Method for making same dye molecule emit light with different colors by substrate induction

A technology of substrates and dyes, applied in the field of fluorescent dye molecules, can solve the problems of waste, not being used, and unable to be regulated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

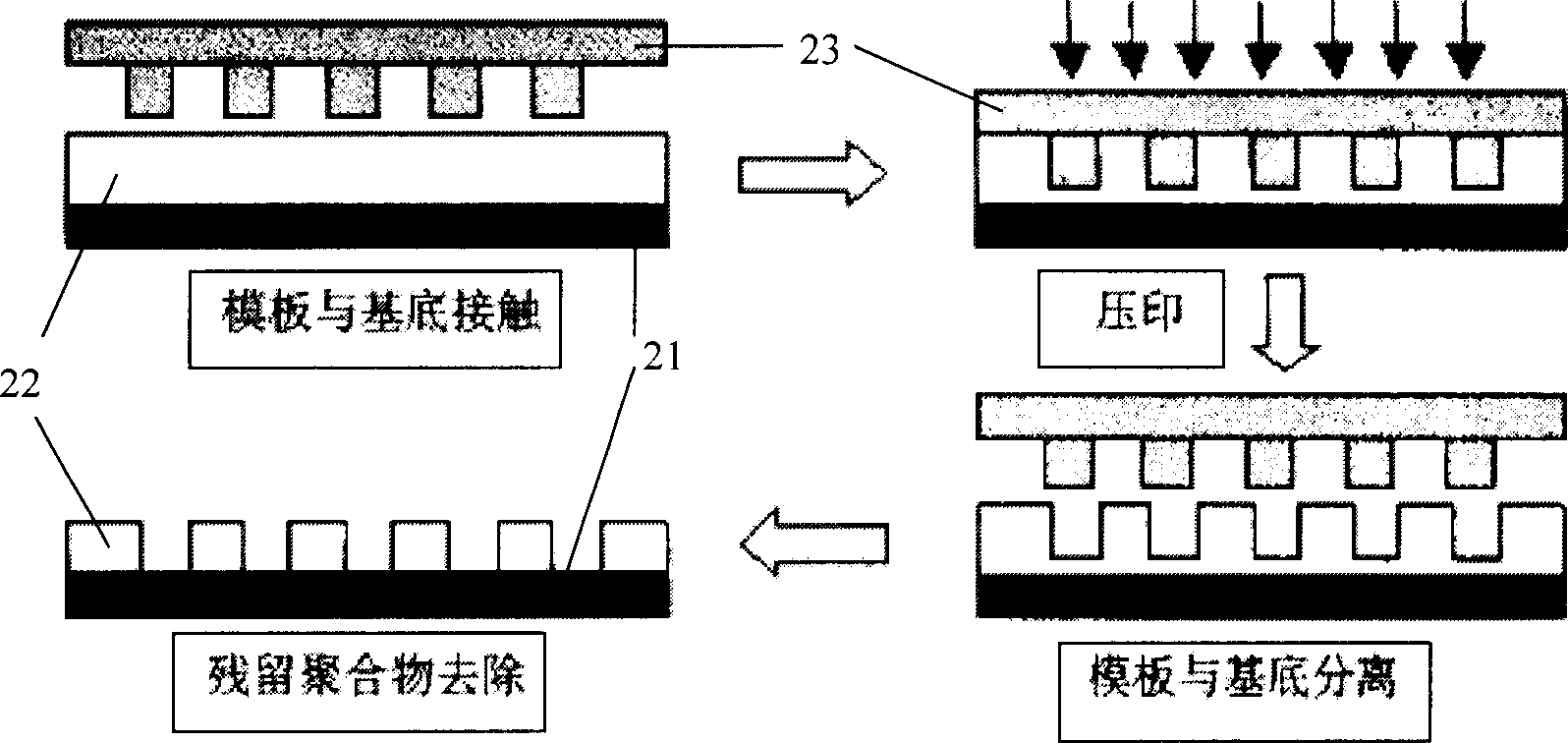

Method used

Image

Examples

Embodiment 1

[0067] Take 10ml of PDMS (Silicone elastomer KIT 184, Daw corning, KIT 184 type silicone rubber, Dow Corning Company) prepolymer, add 500mg of polymerization initiator, stir well, let it stand to remove air bubbles, then pour it into a plastic petri dish and let it stand for 2 hours, and then placed in an oven at 70°C for heating and polymerization for 6 hours. Cut out 1 cm x 2 cm slices (thickness 1.5 mm).

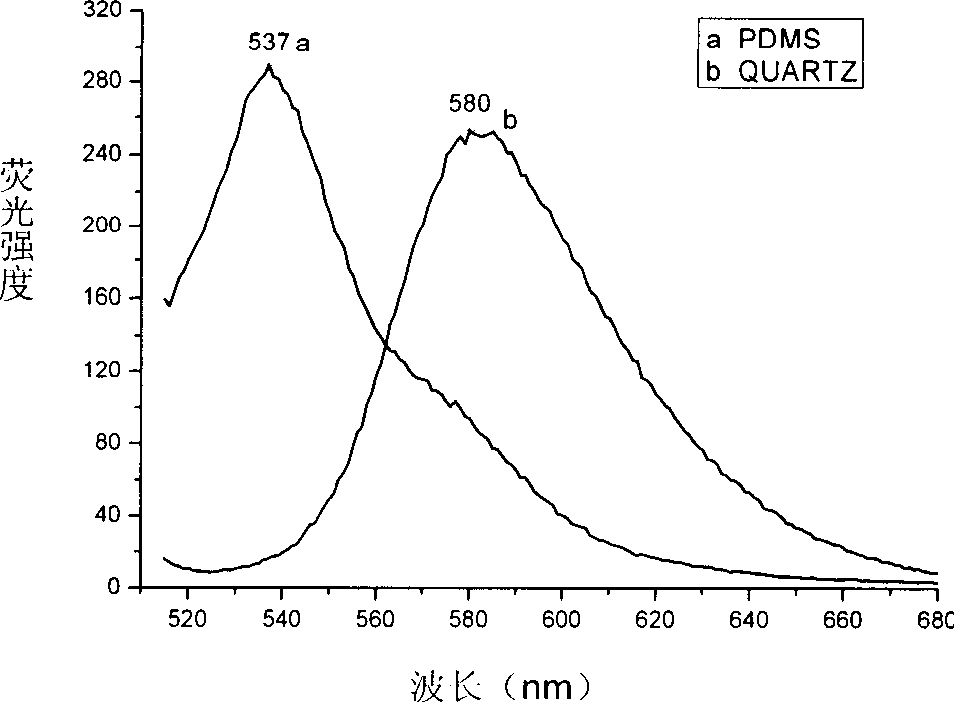

[0068] Take the PDMS sheet and the quartz sheet with a thickness of 1.5mm of 1cm×2cm respectively, and vapor-deposit quinacridone with a thickness of 5nm-500nm. Under the excitation of 495nm incident light, the obtained fluorescence spectrum is shown in Fig. 1(a). The peak on quartz is 580nm, and the corresponding fluorescent color is orange; the peak on PDMS is 537nm, and the corresponding fluorescent color is green. That is, the same dye molecule emits different colors of fluorescence under the same conditions due to different substrate materials.

[0069] Similarly,...

Embodiment 2

[0071] Alkyl silylating reagents (Octadecyltrimethoxysilane, tech., 90%, Sigma-aldrich.inc) were assembled on the surface of single crystal silicon by liquid phase assembly (5 μg / ml toluene solution of alkyl silylating reagents, soaked for 2 h). Fluorosilylating reagent ((Heptadecafluoro-1, 1.2, 2-tetrahydradecyl) triethoxysilane, C 16 h 19 f 17 o 3 Si, ABCR GmbH&Co.KG) was assembled onto the surface of single crystal silicon (5 μl of fluorosilylating reagent was added dropwise, the pressure was maintained at 0.012±0.002Mpa, and the deposition was carried out for 30min).

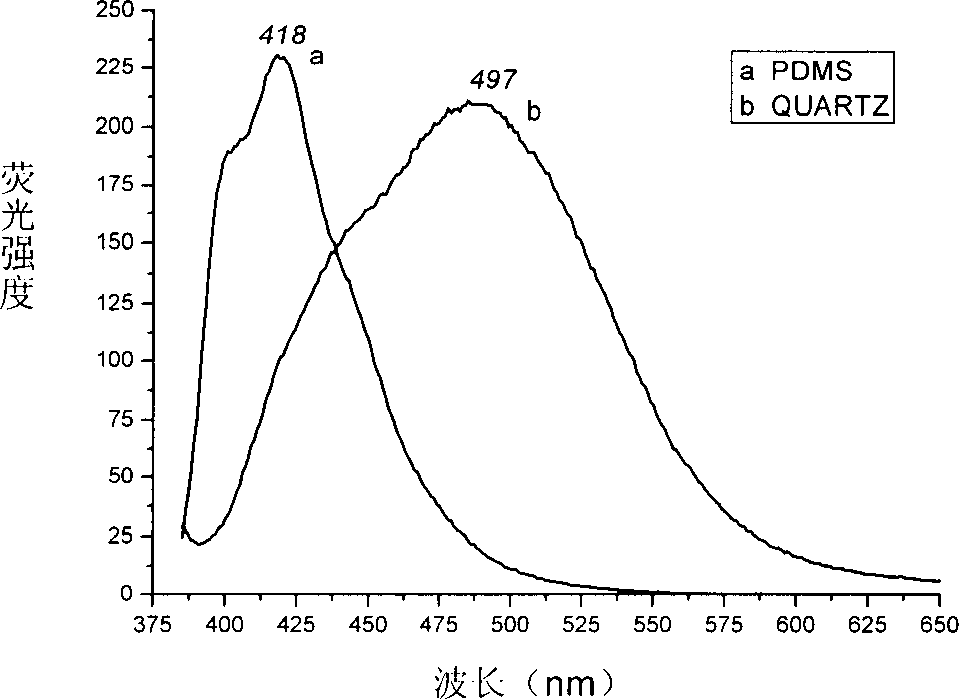

[0072] The monocrystalline silicon treated above was taken, and ANP with a thickness of 5 nm was vapor-deposited. Fluorescence spectrophotometer tests show that the fluorine-modified single crystal silicon emits blue (418nm) fluorescence, while the alkyl-modified single crystal silicon emits green (478nm) fluorescence (such as Figure 4 ).

[0073] Implementation column 3:

[0074] Controlling the liqu...

Embodiment 4

[0078] Extract tar acid (purity > 99%, C 23 h 47 COOH (purchased from Lardan Fine Chemicals, Malmo, Sweden) was vapor-deposited with 5 nm of pyrazolene on a monolayer film.

[0079] Preparation parameters of LB film: V 0 = 20 μl, C 1 =1 mg / ml, CHCl 3 solution, t 1 = 30min,

[0080] S 1 =15cm 2 / min, P=22mN / m, t 2 = 30min, S 2 =2mm / min

[0081] The aggregation state of pyrazolene observed by atomic force microscope Tapping mode is shown in Figure 6. Figure a shows the aggregation state of pyrazole anthracene on the freshly peeled mica, which is irregularly aggregated, and the light-colored part is pyrazole anthracene; Figure b It is the aggregation state of pyrazolene on the single-layer film of tar acid extracted by LB technology on the mica sheet. This example proves that the single-layer film structure can induce different aggregation states of dye molecules with a thickness of several nanometers to tens of nanometers, so that regular or irregular pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com