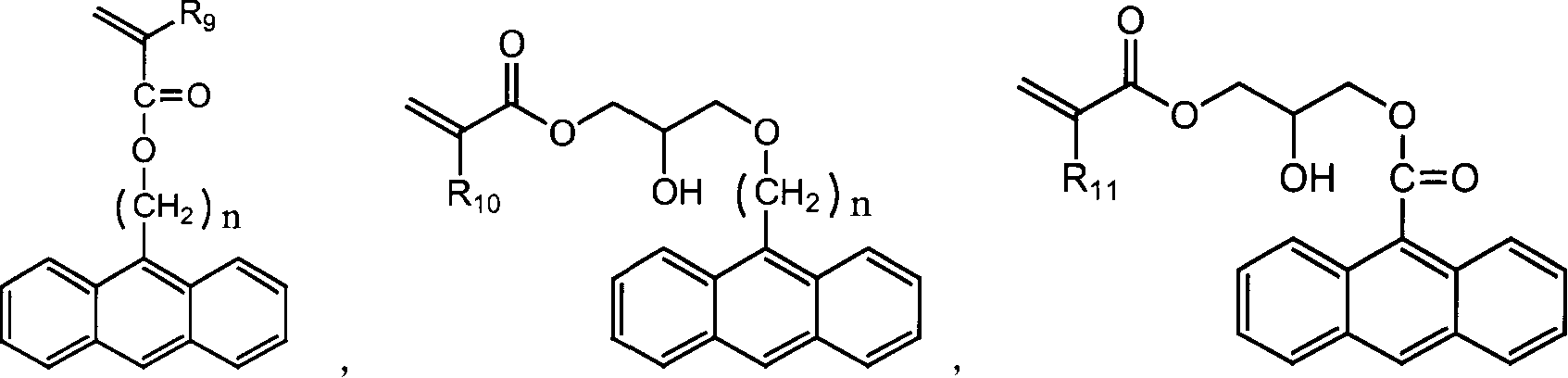

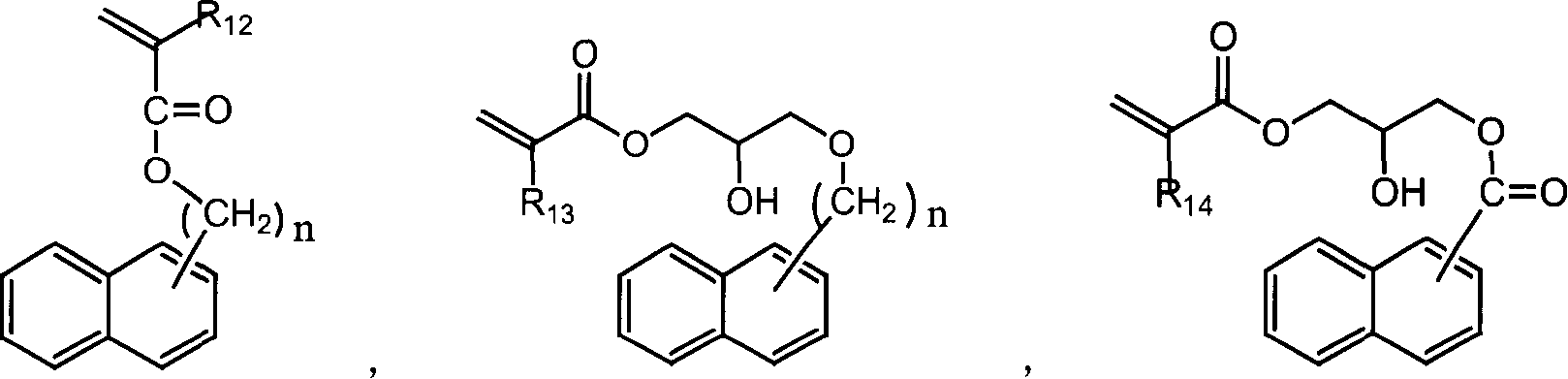

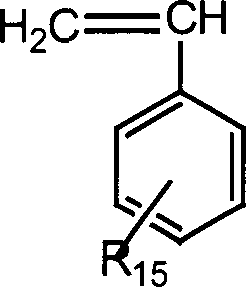

Filming copolymer resin containing silicon coupler and its organic antiflecting coating

A technology of film-forming resin and silicon coupling agent, which is applied in the direction of coating and photosensitive materials used in optomechanical equipment, etc. It can solve the problems of photolithographic pattern deformation, affecting the smoothness and flatness of the coating film, and insufficient etching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0140] (1). Synthesis of 9-anthracene methyl methacrylate:

[0141]

[0142] In a 1000ml three-neck flask equipped with an electric stirrer, condenser, thermometer, temperature controller, heating mantle and nitrogen inlet, add 104 grams of 9-methylanthracenol, 40.0 grams of pyridine, and 300 grams of tetrahydrofuran. Slowly add 54.5 g of methacrylic acid chloride. After heating to 60-65°C and continuing to stir for 6 hours, the solid was removed by filtration. Add 300 g of ethyl acetate, wash with water three times, and concentrate in vacuo to obtain the product 9-anthracene methyl methacrylate with a yield of 82%.

[0143] (2). A copolymer film-forming resin containing a silicon coupling agent, prepared from the following comonomers and their contents, in the presence of a free radical initiator, by heating for copolymerization. The chemical formula (not representing sequence structure) of copolymer film-forming resin is as follows:

[0144]

[0145] 48.3 grams of 9...

Embodiment 2

[0150] (1). Synthesis of 9-anthracene ethyl methacrylate:

[0151]

[0152] In a 1000ml three-neck flask equipped with an electric stirrer, condenser, thermometer, temperature controller, heating mantle and nitrogen inlet, add 111.0 grams of 9-ethylanthracenol, 40.0 grams of pyridine, and 300 grams of tetrahydrofuran. Slowly add 54.5 g of methacrylic acid chloride. After heating to 60-65°C and continuing to stir for 6 hours, the solid was removed by filtration. Add 300 g of ethyl acetate, wash with water three times, and concentrate in vacuo to obtain the product 9-anthraceneethyl methacrylate with a yield of 81%.

[0153] (2). A copolymer film-forming resin containing a silicon coupling agent, prepared from the following comonomers and their contents, in the presence of a free radical initiator, by heating for copolymerization, the copolymer film-forming The chemical formula of the resin (not indicating the sequence structure) is as follows:

[0154]

[0155] 50.7 gr...

Embodiment 3

[0160] (1). Synthesis of [-2-hydroxyl-3-(9-anthracenemethyl)]propyl methacrylate:

[0161]

[0162] In a 1000ml three-neck flask equipped with electric stirrer, condenser, thermometer, temperature controller, heating mantle and nitrogen inlet, add 104 grams of 9-anthracene methyl alcohol, 40.0 grams of tetramethylamino ammonium hydroxide (TMAH) , 300 grams of propylene glycol monomethyl ether (PGME). Slowly add 72.5 grams of glycidyl methacrylate, heat to 120-125°C, and continue stirring for 24 hours. Add 300 g of ethyl acetate, wash with water three times, and concentrate in vacuo to obtain the product [-2-hydroxyl-3-(9-methylanthracene)]propyl methacrylate with a yield of 82%.

[0163] (2). A copolymer film-forming resin containing a silicon coupling agent, prepared from the following comonomers and their contents, in the presence of a free radical initiator, by heating for copolymerization, the copolymer film-forming The chemical formula of the resin (not indicating th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com