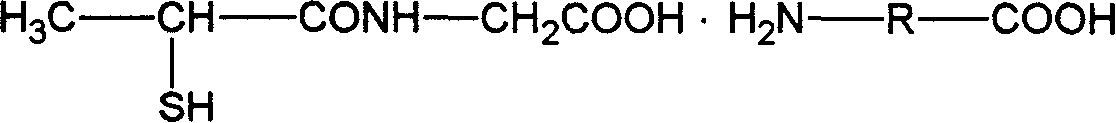

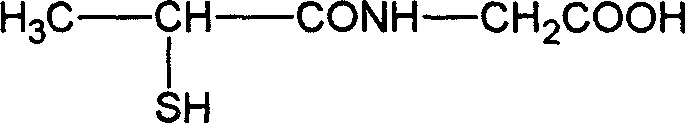

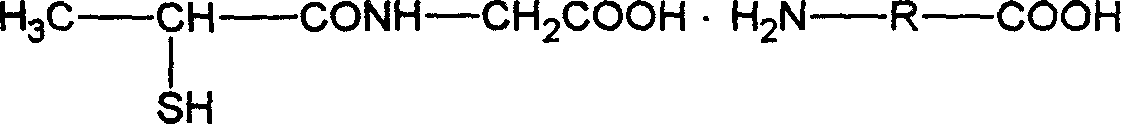

Tiopronin amino salt, and its preparing method

A technology of tiopronin amino acid salt and arginine salt, which is applied in the field of tiopronin amino acid salt and its preparation, and can solve the problems of easy oxidative degradation, limitation of tiopronin, thermal stability of tiopronin easy oxidative degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the preparation of tiopronin arginine salt

[0023] raw material name

Feeding amount

L-Arginine

Methanol (95%)

100g

112g

600ml

1

1.05

[0024] operate:

[0025] Put tiopronin, L-arginine, and ethanol into a 1000ml three-necked reaction flask, stir, heat to 50°C for reflux, and after 3 hours of reflux reaction, filter while hot, and place the filtrate in a refrigerator at 5-10°C to cool and crystallize. After 5 hours, it was filtered to obtain white crystals, which were dried in an oven at 80°C for 6 hours to obtain 196 g of white crystalline solids, yield 94.8%, mp 197-200°C.

[0026] The infrared absorption spectrum data of the sample:

[0027] Absorption peak (cm -1 ): 2957.92, 1647.58, 1604.88, 1525.77, 1457.23, 1407.90, 1386.21, 1357.38, 1335.77, 1313.99, 1246.37, 1159.37, 1012.96, 670.43, 555.97.

Embodiment 2

[0028] Embodiment 2: the preparation of tiopronin lysine salt

[0029] raw material name

Feeding amount

Tiopronin

L-Lysine

Ethanol (95%)

100g

94g

600ml

1

1.0

[0030] The operation method is the same as in Example 1: 177g of white crystalline solid was obtained, yield 93.4%, mp 172-175°C.

[0031] The infrared absorption spectrum data of the sample:

[0032] Absorption peak (cm -1 ): 3328.57, 2939.20, 1646.85, 1593.90, 1521.17, 1405.00, 1357.70, 1316.94, 1023.31, 904.87, 701.58, 550.03, 420.12.

Embodiment 3

[0034] Put tiopronin and phenylalanine salt into a 1000ml three-necked reaction flask at a ratio of 1:0.8, then add 650ml of ethyl acetate for stirring, heat to reflux at 100°C, and after 3 hours of reflux reaction, filter while hot, and place the filtrate in Cool and crystallize in the refrigerator at 5-10°C. After 5 hours, it was filtered to obtain white crystals, which were dried in an oven at 80° C. for 6 hours to obtain 196 g of white crystalline solids, yield 94.2%, mp 195-200° C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com