Prepn process of nanometer silicon line array

A silicon nanowire array and silicon wafer surface technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve problems such as difficulty in obtaining uniformly arranged nanowires in diameter, and difficulty in controlling the diameter of silicon wires. The effect of orderly layout, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

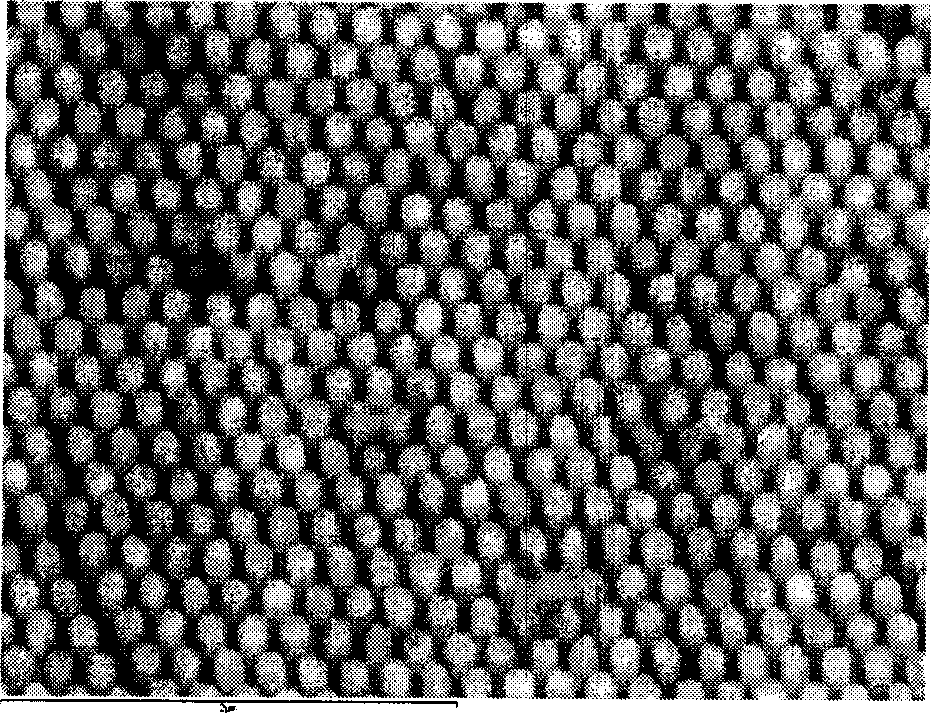

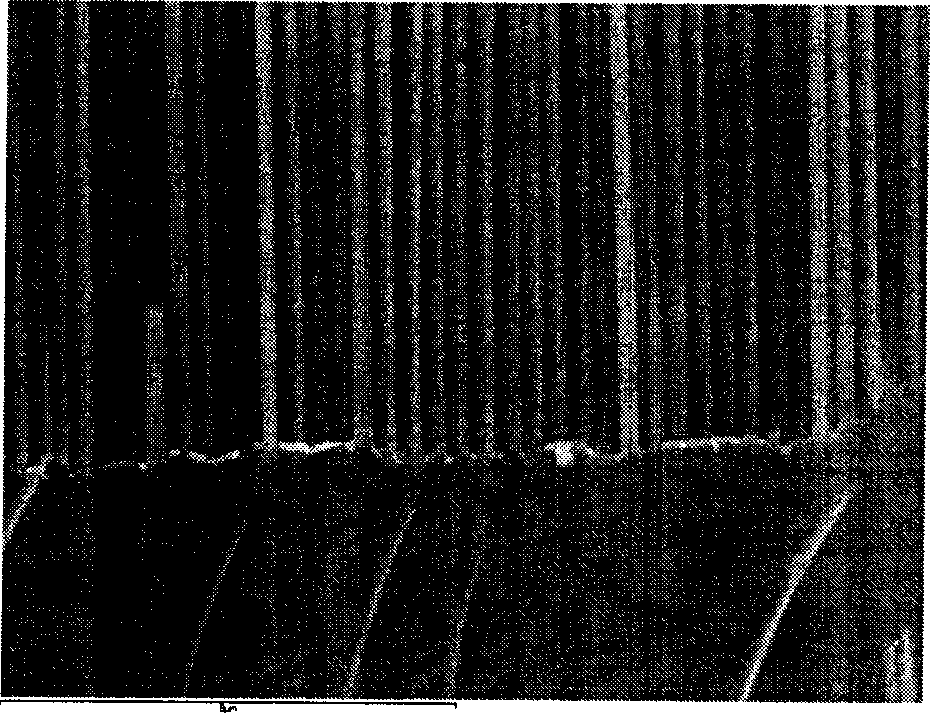

[0027] According to the surface area of the substrate, the solution of polystyrene beads with a concentration of 0.01% was dropped onto the surface of the cleaned silicon wafer, dried and kept at 90° C. for 6 minutes. Perform reactive ion etching on the PS balls for 60 ± 5 seconds, and then use a vacuum evaporation device to vapor-deposit a 25nm (± 3nm) thick Ag film on the surface of the silicon wafer where the PS ball array is arranged, and then deposit a silver film The sample was immersed in a closed container kettle containing a mixed solution of hydrofluoric acid and hydrogen peroxide (the concentrations of hydrofluoric acid and hydrogen peroxide were 1.15mol / L and 0.44mol / L respectively) and treated for 10 minutes, and a large area of organic matter could be obtained. array of silicon nanowires.

Embodiment 2

[0029] According to the surface area of the substrate, the solution of polystyrene beads with a concentration of 0.09% was dropped onto the surface of the cleaned silicon wafer, dried and kept at 90° C. for 10 minutes. Perform reactive ion etching on the PS balls for 80±5 seconds, and then use a vacuum evaporation device to vapor-deposit a 40nm (±5nm) thick Ag film on the surface of the silicon wafer where the PS ball array is arranged, and then deposit a silver film The sample was immersed in a closed container kettle containing a mixed solution of hydrofluoric acid and hydrogen peroxide (the concentrations of hydrofluoric acid and hydrogen peroxide were 2.3mol / L and 0.88mol / L respectively) and treated for 30 minutes, and a large area of organic matter could be obtained. array of silicon nanowires.

Embodiment 3

[0031] According to the surface area of the substrate, the solution of polystyrene beads with a concentration of 0.1% was dropped onto the surface of the cleaned silicon wafer, dried and kept at 100° C. for 20 minutes. Perform reactive ion etching on the PS balls for 120 ± 5 seconds, and then use a vacuum evaporation device to vapor-deposit a 40nm (± 5nm) thick Ag film on the surface of the silicon wafer where the PS ball array is arranged, and then deposit a silver film The sample was immersed in a closed container kettle containing a mixed solution of hydrofluoric acid and hydrogen peroxide (the concentrations of hydrofluoric acid and hydrogen peroxide were 2.3mol / L and 1.76mol / L respectively) and treated for 20 minutes, and a large area of organic matter could be obtained. array of silicon nanowires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com