Method for making amine-modified epoxy resin and cationic electrodeposition coating composition

A cationic electrodeposition, epoxy resin technology, applied in the direction of epoxy resin coating, electrophoretic coating, coating, etc., can solve the problems such as prone to pinholes, and achieve the effect of excellent appearance, excellent appearance and high dispersion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0142] Preparation of lead-free cationic electrodeposition paint composition (first embodiment)

[0143] The lead-free cationic electrodeposition coating composition of the present invention is prepared by dispersing the above-mentioned amine-modified epoxy resin, blocked isocyanate curing agent, pigment dispersion paste and catalyst in an aqueous medium. In addition, a neutralizing acid may be included in the aqueous medium to neutralize the cationic epoxy resin and improve the dispersibility of the binder resin emulsion. Examples of acids for neutralization include inorganic acids or organic acids such as hydrochloric acid, nitric acid, phosphoric acid, formic acid, acetic acid, lactic acid, sulfamic acid, acetylglycine and the like. The aqueous medium used here is water or a mixture of water and an organic solvent. The water preferably used is deionized water. Examples of organic solvents used include hydrocarbons (such as xylene or toluene), alcohols (such as methanol, n...

preparation Embodiment 1

[0184] Production Example 1 (1st and 2nd Embodiments)

[0185] Preparation of Blocked Polyisocyanate Curing Agents

[0186]1250 parts of diphenylmethane diisocyanate and 266.4 parts of methyl isobutyl ketone (hereinafter referred to as MIBK) were placed in a reaction kettle, and 2.5 parts of dibutyltin dilaurate were added thereto after heating to 80°C. A solution obtained by dissolving 226 parts of ε-caprolactam in 944 parts of butyl cellosolve was dropped thereto over 2 hours at 80°C. It was reacted at 100°C for 4 hours, and the absorption based on the isocyanate group was confirmed to disappear by infrared spectrum measurement, and allowed to cool. 336.1 parts of MIBK were added to obtain a blocked isocyanate curing agent with a glass transition temperature of 8°C.

preparation Embodiment 2

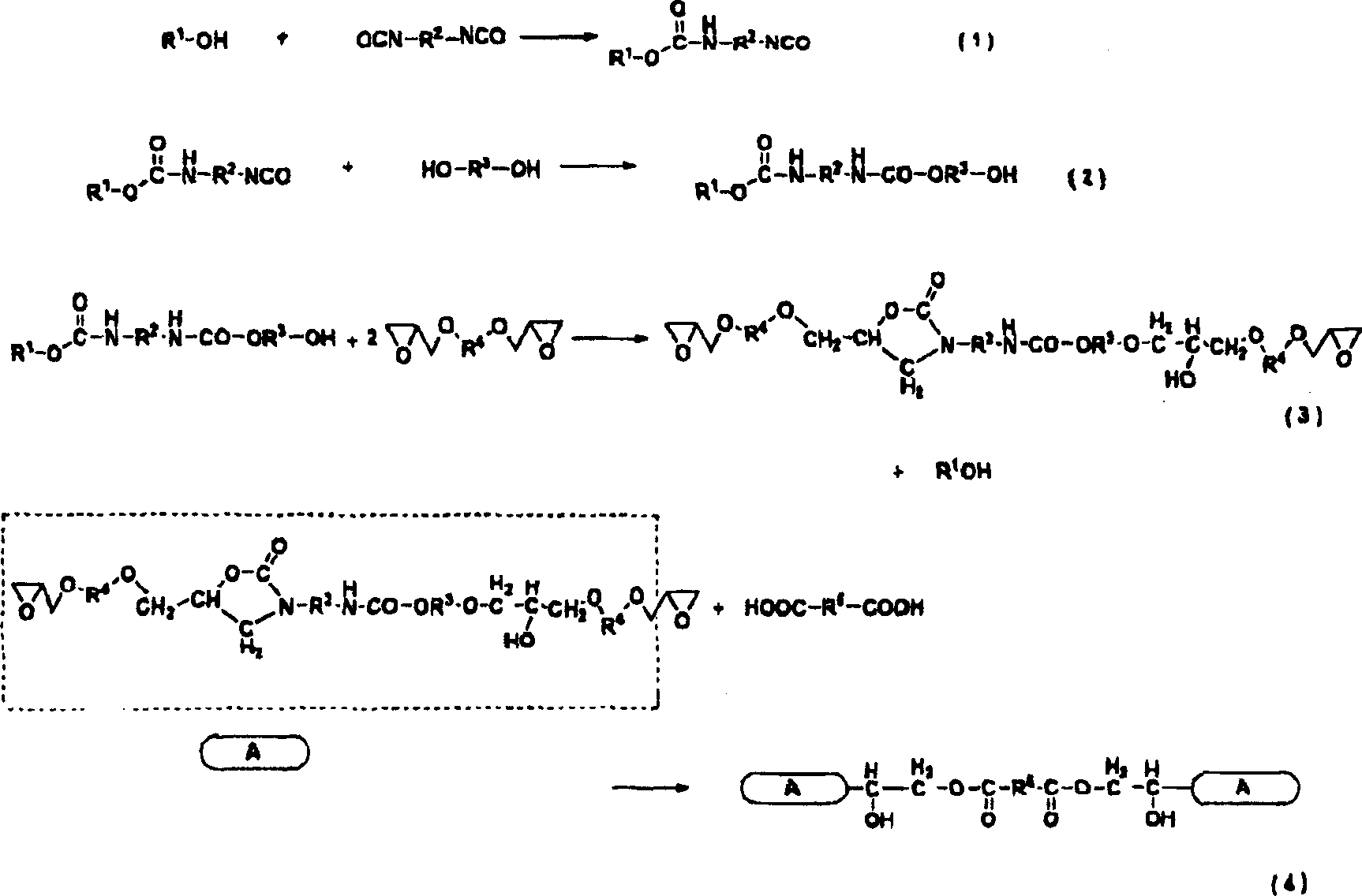

[0188] Preparation of amine-modified epoxy resin (first embodiment)

[0189] 35 parts of 2,4- / 2,6-toluene diisocyanate (weight ratio=8 / 2), 94 parts of MIBK and 0.5 part of dibutyltin dilaurate were placed in a device equipped with agitator, condenser, nitrogen conduit, thermometer and dropping funnel in the flask. While stirring the above reaction mixture, 7 parts of methanol were added thereto. Starting from room temperature, the reaction mixture was heated to 60°C due to exotherm, the reaction was maintained for 30 minutes, and 12 parts of ethylene glycol mono-2-ethylhexyl ether were added dropwise from the dropping funnel. In addition, 33 parts of bisphenol A-propylene oxide 5 mol adduct were added. The reaction is mainly carried out in the temperature range of 60-65 °C until the absorption based on the isocyanate group disappears in the infrared spectroscopic measurement. Next, 383 parts of an epoxy resin having an epoxy equivalent of 188 synthesized from bisphenol A an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com