Light filtering plate with function of preventing electromagnetic radiation and filtering light for plasma display

An anti-electromagnetic radiation and plasma technology, applied in gas discharge tubes/containers, instruments, circuits, etc., can solve the difficulty of controlling film thickness and visible light transmittance, reduce the EMI shielding ability of three-layer silver, and the EMI shielding effect is not enough, etc. problems, to achieve the effect of low cost, increased convenience and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

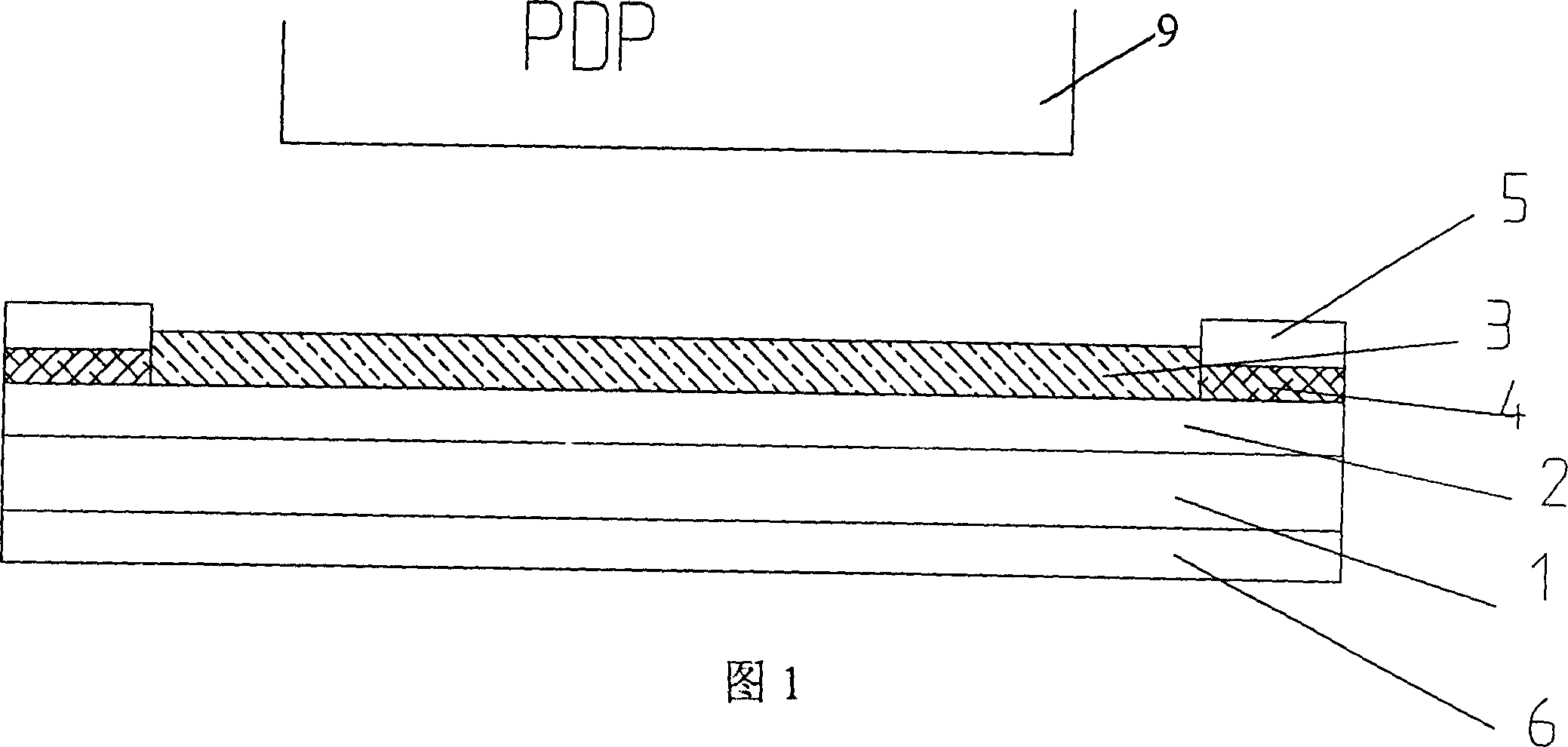

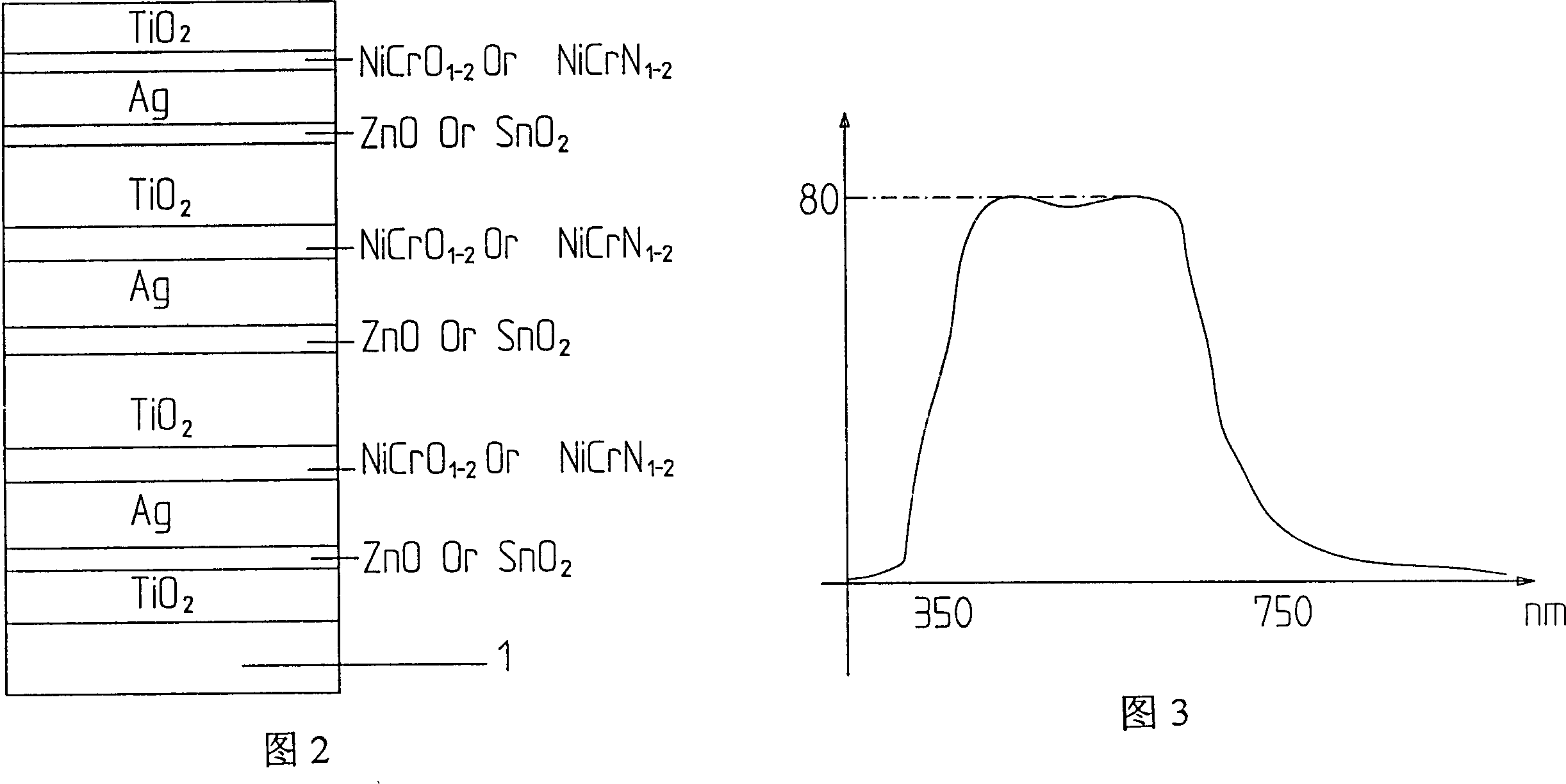

[0026] Figure 1 shows the first diagram of this embodiment. Referring to Figure 1, the substrate 1 is made of 3mm thick optical grade float glass (temperable) or 2mm thick polymethyl methacrylate (PMMA) plastic substrate or 0.2mm thick polyester (PET) substrate, After cleaning with deionized water, it enters the continuous magnetron sputtering coating production line and uses continuous magnetron sputtering to coat the three-silver film system (or four-silver film system) as shown in Figure 2. 2 / ZnO (or SnO 2 ) / Ag / NiCrOx(or NiCrNx) / TiO 2 13-layer film composed of repeating structures (adjacent TiO layers of adjacent structural layers 2 Coating layer with anti-electromagnetic radiation and filter function (ie, EMI shielding coating layer)2, in which TiO 2 , ZnO were prepared by twin intermediate frequency reactive magnetron sputtering, while Ag and NiCrOx were prepared by planar DC magnetron sputtering. If three layers of TiO 2 / ZnO (or SnO 2 ) / Ag / NiCrOx(or NiCrNx) / TiO ...

Embodiment 2

[0029] FIG. 6 shows the structure diagram of the second embodiment. The second embodiment is basically the same as the first embodiment, the difference is that there is no AR film layer on the other side of the substrate, which becomes the most basic type of filter plate.

Embodiment 3

[0031] FIG. 7 is a schematic structural diagram of the third embodiment. This embodiment 3 is basically the same as the embodiment 1, except that the other side of the resin film (or glass substrate) is pasted with a resin sheet 7 (biaxially oriented polyester film BOPET) coated with an anti-reflection layer AR film 6 ), one side of which is plated with AR film 6, and the other side uses acrylic pressure-sensitive adhesive or two-component polyurethane adhesive layer 8 to be pasted and compounded with glass substrate 1, so that the glass substrate becomes Impact-resistant safety glass, and can become a safety screen for PDP displays.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com