Super fine titanium carbonitride powder and its preparing method

A technology of titanium nitride powder and titanium hydride, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve problems such as difficult mass production, polluting the production environment, and low production efficiency, and achieve high efficiency in production and tertiary production , The production process is simple and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

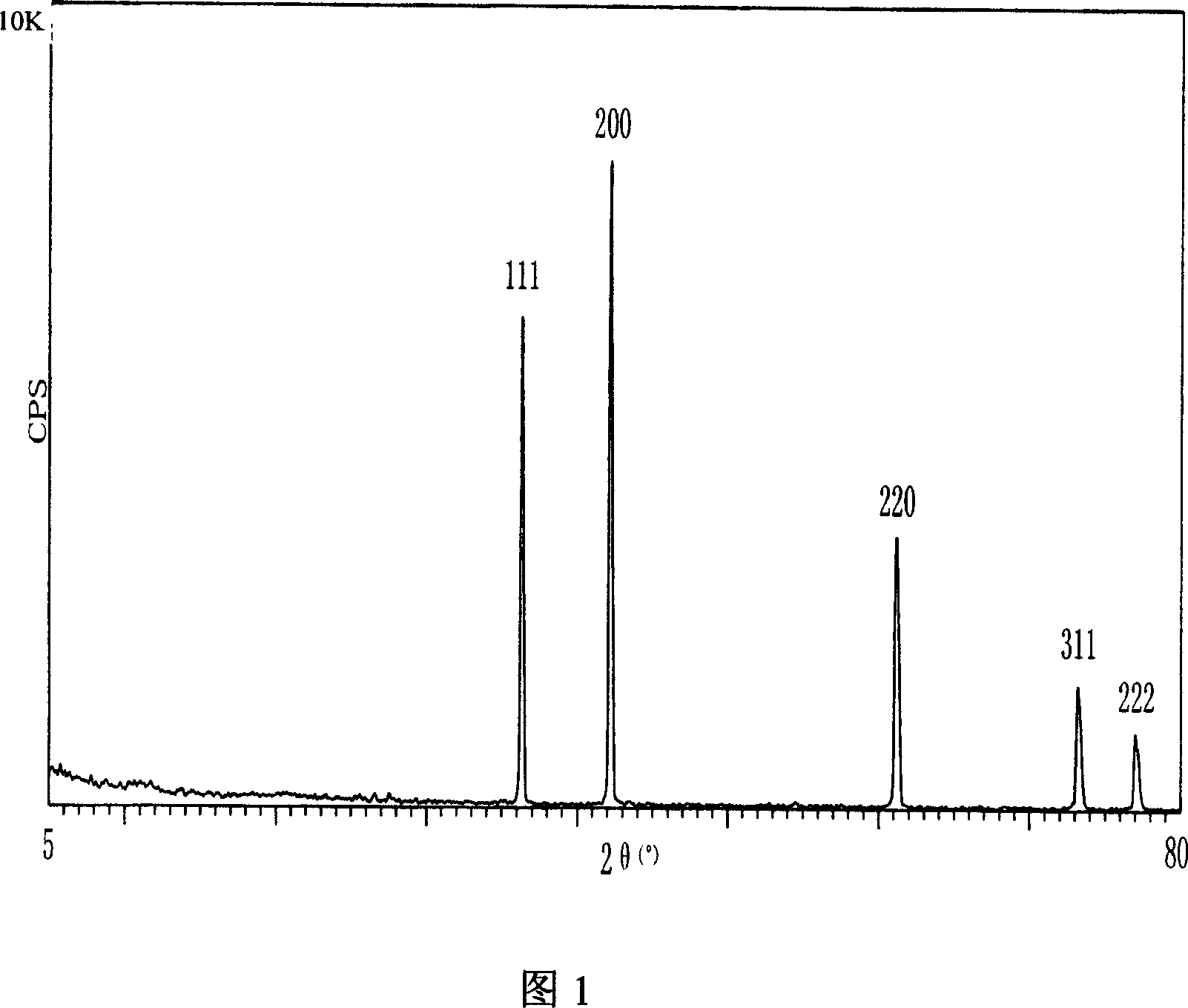

example 1

[0023] Ingredients by weight percentage, starch is 17.2%, titanium hydride is 82.8%, in the polyurethane ball mill tank, with 95% ethanol as medium, with ZrO 2 The ball-to-material ratio is 5:1, and the ball-milling time is 24 hours. The ingredients after ball milling were dried at 60°C, then loaded into a graphite boat, and kept at a constant temperature of 1750°C for 2 hours in a self-made carbon tube furnace. 2 atmosphere (N 2 The red-brown Ti(C,N) ultrafine titanium carbonitride powder was synthesized at high temperature at a flow rate of 3ml / min.

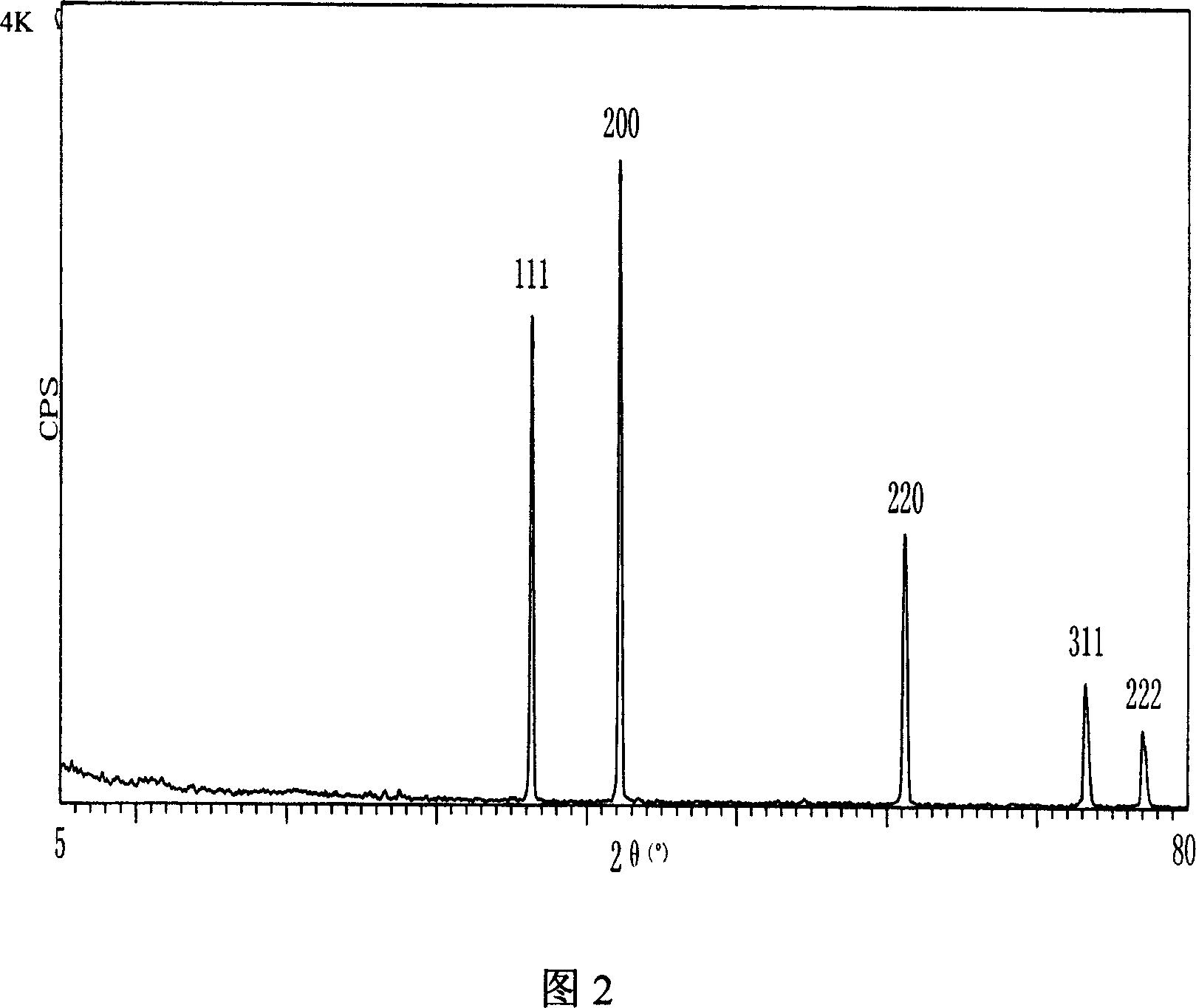

example 2

[0025] Ingredients by weight percentage, starch is 20.6%, titanium hydride is 79.4%, in polyurethane ball mill tank, with 95% ethanol as medium, with ZrO 2 The ball-to-material ratio is 5:1, and the ball-milling time is 24 hours. The ingredients after ball milling were dried at 60°C, then loaded into a graphite boat, and kept at 1700°C for 2 hours in a self-made carbon tube furnace, and then heated under N 2 atmosphere (N 2 The red-brown Ti(C,N) ultrafine titanium carbonitride powder was synthesized at high temperature at a flow rate of 3ml / min.

example 3

[0027] Ingredients by weight percentage, starch is 13.5%, titanium hydride is 86.5%, in the polyurethane ball mill tank, with 95% ethanol as medium, with ZrO 2 The ball-to-material ratio is 5:1, and the ball-milling time is 24 hours. The ingredients after ball milling were dried at 60°C, then loaded into a graphite boat, and kept at 1800°C for 2 hours in a self-made carbon tube furnace. 2 atmosphere (N 2 Brown-red Ti(C,N) ultrafine titanium carbonitride powder was synthesized at high temperature at a flow rate of 6ml / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com