Reduced preparation method for metal nanometer particle using hydroxy ion liquid

A technology of metal nanoparticles and ionic liquids, which is applied in the field of nano powder preparation, can solve the problems of a large amount of waste liquid, waste gas, complex methods, environmental pollution, etc., and achieve the advantages of avoiding the introduction of impurities, simple preparation process and high product purity Effect

- Summary

- Abstract

- Description

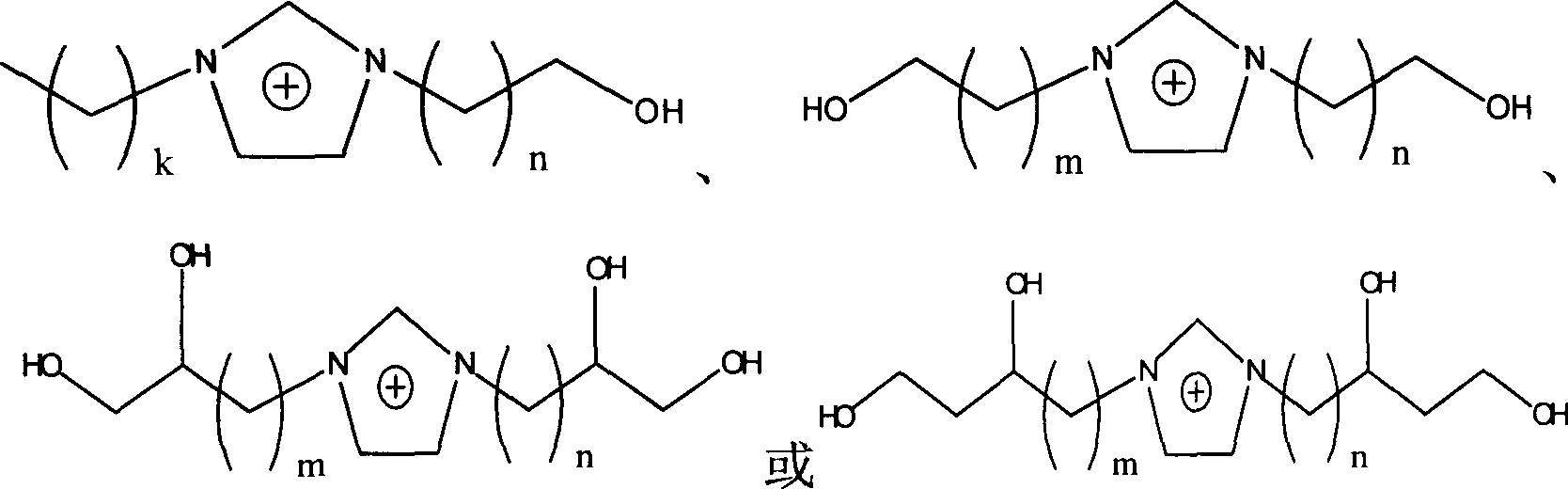

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

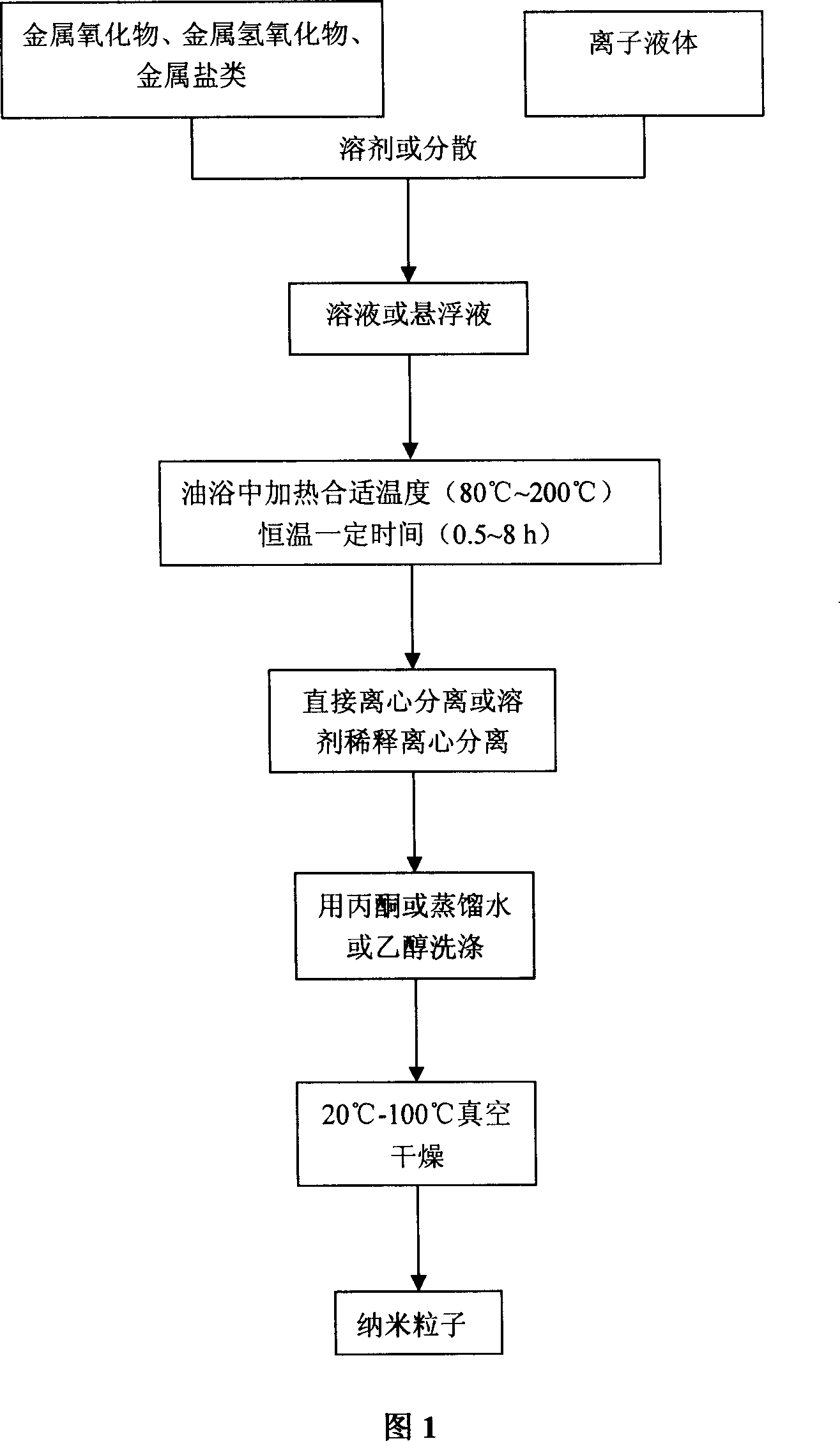

Method used

Image

Examples

Embodiment 1

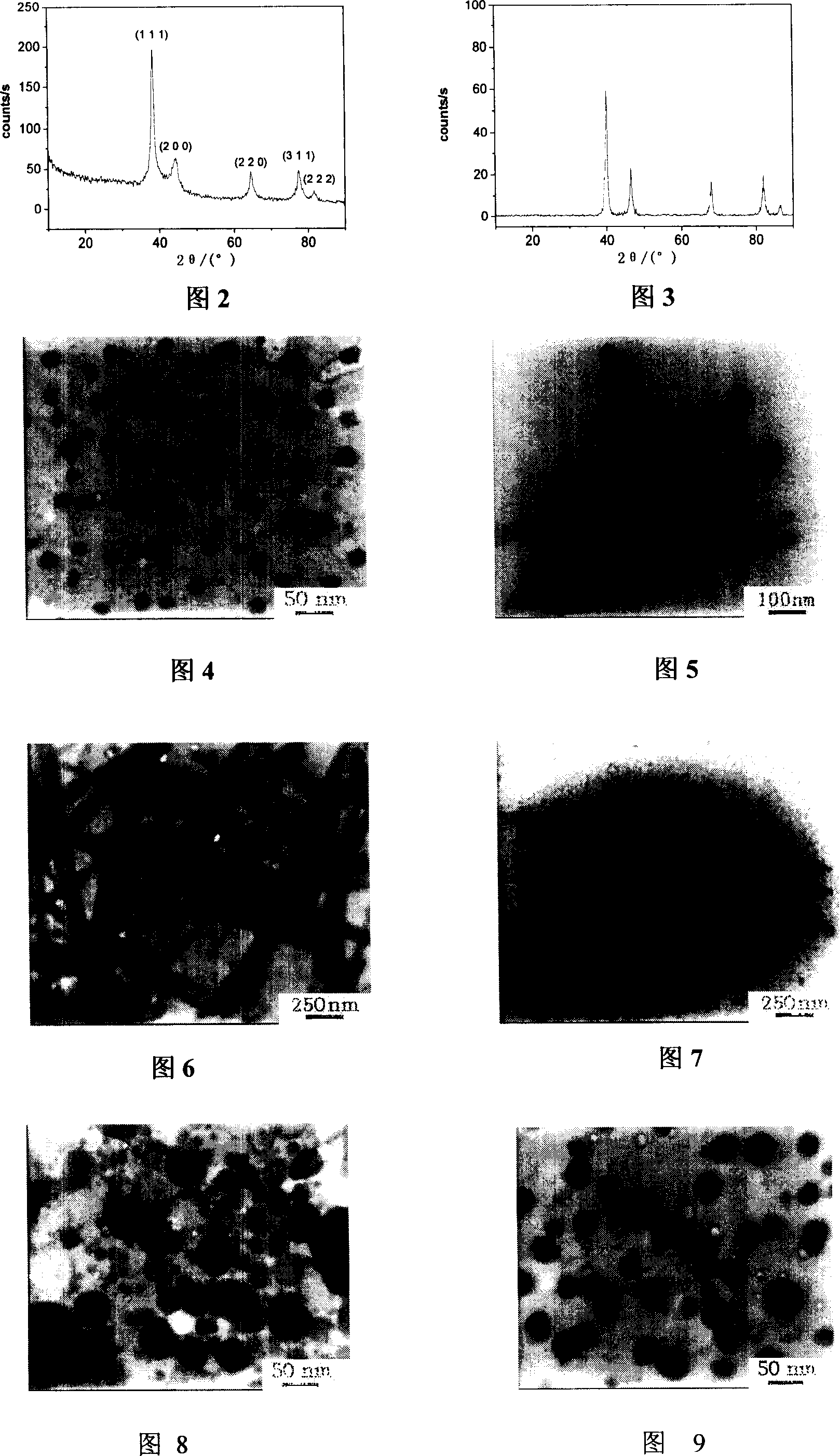

[0033] Example 1 Preparation of Ag nanoparticles

[0034] (1) Preparation of ionic liquid: Take 0.48mol chloroethanol and 0.32mol methylimidazole and reflux in 80°C oil bath for 24h. After the reaction, a viscous colorless transparent liquid is obtained. When the temperature drops to normal temperature, the amount of heat released becomes The solid was washed four times with ether to obtain a colorless crystal 1-hydroxyethyl-3-methylimidazolium chloride ionic liquid, which was dried in a vacuum oven at 80°C for 48 hours, and the dried 1-hydroxyethyl-3-methylimidazole Add 25g (0.15mol) of chloride ionic liquid into 150mL acetone, then add 19g (0.17mol) sodium fluoroborate, stir at room temperature for 24 hours, and filter with suction. The filter residue is a waxy solid, which is washed twice with acetone. Anhydrous MgSO 4 After drying overnight, the acetone was evaporated by rotary evaporation at 40°C, and then the water was evaporated by rotary evaporation in an oil bath at ...

Embodiment 2

[0036] Example 2 Preparation of Ag nanorods

[0037] (1) Weigh 0.85g AgNO 3 Dissolve in 50mL of distilled water, add 0.5g of thioglycolic acid dropwise after dissolving, a large amount of light yellow precipitates will gradually appear in the solution after mixing, after the addition of thioglycolic acid is completed, react for another hour, filter under normal pressure, and wash the product three times with distilled water , vacuum-dried at normal pressure, and finely ground after drying to obtain silver thioglycolate powder;

[0038] (2) Preparation of ionic liquid: 1-(4'-hydroxyl) butyl-3-methylimidazolium tetrafluoroborate ([C 4 OHmim] BF 4 ) The preparation steps of ionic liquid are the same as in Example 1;

[0039] (3) Add 10 mg of silver thioglycolate to 5 mL of 1-(4'-hydroxy)butyl-3-methylimidazolium tetrafluoroborate ([C 4 OHmim] BF 4 ) in the ionic liquid, ultrasonically dispersed, heated on an oil bath at 160°C for 4 hours, cooled to room temperature, centrifu...

Embodiment 3

[0040] Example 3 Preparation of Ag nanowires

[0041] (1) Preparation of ionic liquid: 1-(6'-hydroxyl) hexyl-3-methylimidazolium tetrafluoroborate ([C 6 OHmim] BF 4 ) The preparation steps of the ionic liquid are the same as in Example 1;

[0042](2) preparation of silver thioglycolate: with embodiment 2;

[0043] (3) Add 10 mg of silver thioglycolate to 5 mL of 1-(6'-hydroxyl) hexyl-3-methylimidazolium tetrafluoroborate ([C 6 OHmim] BF 4 ) in the ionic liquid, ultrasonically disperse it, keep the temperature in an oil bath at 160°C for 6 hours, cool to room temperature, and centrifuge the product, wash it four times with distilled water, and finally dry it under vacuum at room temperature. That is, Ag nanowires are obtained. The diameter distribution of the prepared Ag nanowires is wide, distributed between 40-100nm, and the length exceeds 5μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com