Preparation of electrocatalysis electrode of Nano carbon fiber in use for organic electrochemical synthesis process

A technology of nano-carbon fiber and chemical synthesis, applied in electrolysis process, electrodes, electrolysis organic production, etc., can solve problems such as human health hazards, electrode inactivation, affecting production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 0.1 gram of tubular carbon nanofibers, add water, make the mass percent of the nanocarbon fiber mixed liquid A obtained through ultrasonic dispersion be 25%, weigh 0.25 grams of polytetrafluoroethylene solution with a mass percent of 60%, add 2.25 grams of water , diluted to 6% polytetrafluoroethylene solution B in mass percent. In a water bath at 80°C, put the mixed liquid A into a beaker, and gradually add solution B under vigorous stirring. Continue to stir until a gel forms. Afterwards, the obtained jelly was uniformly coated on the nickel foam, and then pressed into a tablet at 250° C. under a pressure of 5 MPa to prepare a carbon nanofiber electrocatalyst.

[0023] The prepared carbon nanofiber electrocatalyst was embedded in 0.05mol / L Pb(NO 3 ) 2 in solution. The constant potential deposition was carried out under the conditions of a deposition temperature of 25° C. and a potential of −0.85 V (relative to a saturated calomel electrode), and the depositi...

Embodiment 2

[0028] Weigh 1 g of herringbone carbon nanofibers and weigh 0.5 g of polyethylene glycol with a purity of 100% in a ratio of 2:1. Fully mix the carbon nanofibers and polyethylene glycol, press into a tablet under a pressure of 5MPa at room temperature, and then add 0.05mol / L of Pb(AC) 2 in solution. The cyclic voltammetry scan was carried out under the conditions of a temperature of 10°C and a potential range of -0.35--0.95V to deposit metal, and the scan time was 30 minutes. Afterwards, the obtained electrocatalyst electrode was washed with ultrapure water until the pH was neutral.

[0029] Put the obtained carbon nanofiber electrocatalyst electrode into the oxalic acid solution of 0.5mol / L, in the negative electrode in the H-type electrolyzer, with 1500A / m 2 constant current electrolysis. After 6h electrolysis, the average current efficiency is 75%.

Embodiment 3

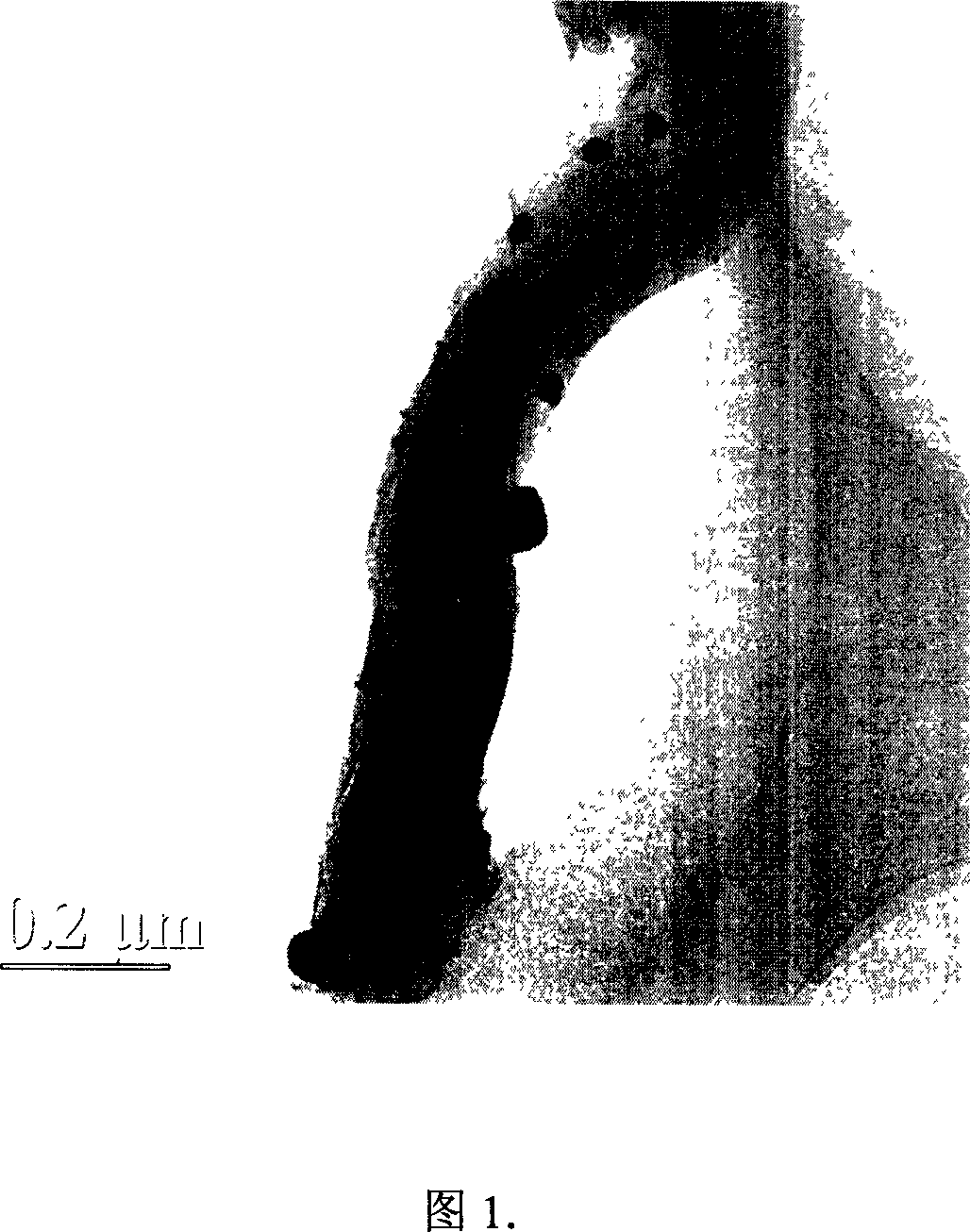

[0031] Weigh 5 mg plate-type carbon nanofibers and add 1 ml of 0.5 wt% Nafion solution (Dupont Corp.). After ultrasonic dispersion, 10 μL of the mixed liquid was dropped on a glassy carbon electrode with a diameter of 3 mm with a pipette gun, and then dried naturally in an air atmosphere for 1 h, and then placed in 0.05 mol / L Pb(COO) 2 In the solution, constant potential electrodeposition was carried out in the potential range of -0.95V for 5 minutes. Afterwards, the obtained electrocatalyst electrode was washed with ultrapure water until the pH was neutral, and the morphology of the electrode was observed with HRTEM.

[0032] Put the obtained carbon nanofiber electrocatalyst electrode into the electrolyte solution containing 20% acrylonitrile, with 2000A / m 2 The current density of constant current electrolysis is carried out in the cathode of the H-type electrolyzer. After 6h electrolysis, the average current efficiency is 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com