Prepn process of nanometer nickel sulfide rod

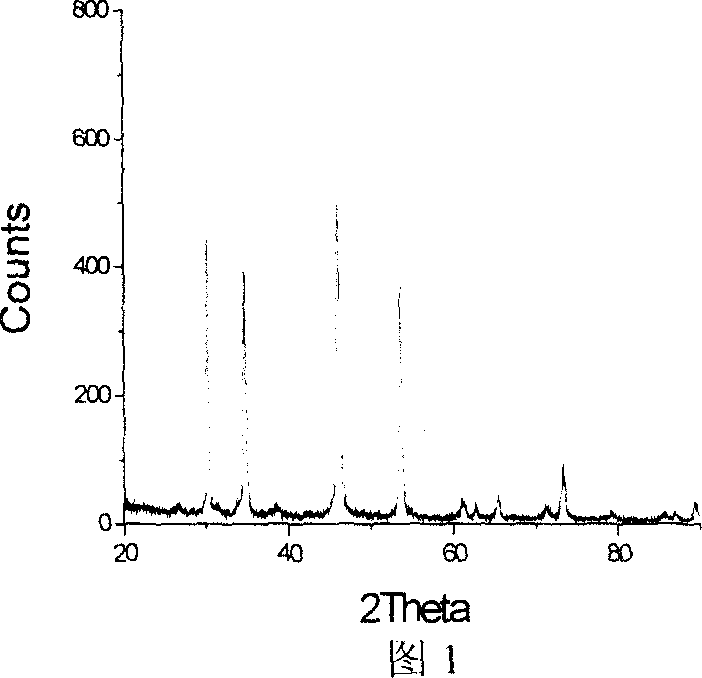

A technology of nano-rods and nickel sulfide, applied in the direction of nickel sulfide, etc., can solve the problems of complex precursor preparation process, non-single reaction product, and difficult control of product shape, and achieve high yield, short reaction time, and thermal stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

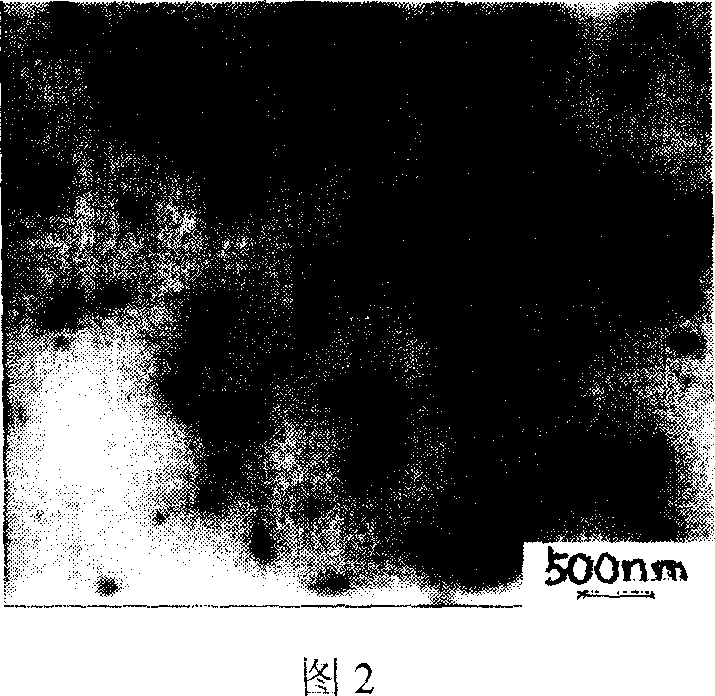

[0025] Embodiment 1, the preparation steps of nickel sulfide nanorods are: (1) preparation of nickel octane sulfonate: take 0.005molNiSO 4 ·6H 2 O was dissolved in water, weighed 0.01mol octane potassium sulfonate and dissolved in methanol, and added the nickel sulfate aqueous solution dropwise into the potassium sulfonate solution to obtain a khaki-yellow precipitate immediately. After the dropwise addition, fully stir. The resulting mixture was filtered with suction, and the filter cake was washed three times with methanol:water at a ratio of 3:1 (volume ratio), and then washed once with methanol, filtered with suction, and the filter cake was vacuum-dried for later use. The resulting product is nickel octane sulfonate. (2) Preparation of ionic liquid: methylimidazole and hexyl bromide 1:1 (molar ratio) were added to the flask, the temperature of the oil bath was slowly raised to 60°C and stirred for 5 hours, then cooled to room temperature, dissolved in distilled water, an...

Embodiment 2

[0028] Embodiment 2, the preparation steps of nickel sulfide nanorods are: (1) Preparation of nickel cetyl sulfonate: the raw material is potassium cetyl sulfonate, and the preparation method is the same as in Example 1. (2) Preparation of ionic liquid: the raw material was changed to potassium hexafluorophosphate, and the preparation method was the same as in Example 1. (3) Preparation of nickel sulfide nanorods: Add 0.03g of nickel hexadecyl sulfonate and 3mL of 1-hexyl-3-methylimidazolium hexafluorophosphate ionic liquid into a 50mL single-necked bottle, and gently stir with a magnetic stirrer. Stir to disperse nickel cetyl sulfonate evenly in the ionic liquid, put the one-necked bottle into the oil bath, and slowly heat the oil bath from room temperature to 170°C, while stirring magnetically, keep it for 5 minutes, then place the one-necked bottle After the solution is cooled to room temperature, the product is separated by centrifugation, and the separated product is wash...

Embodiment 3

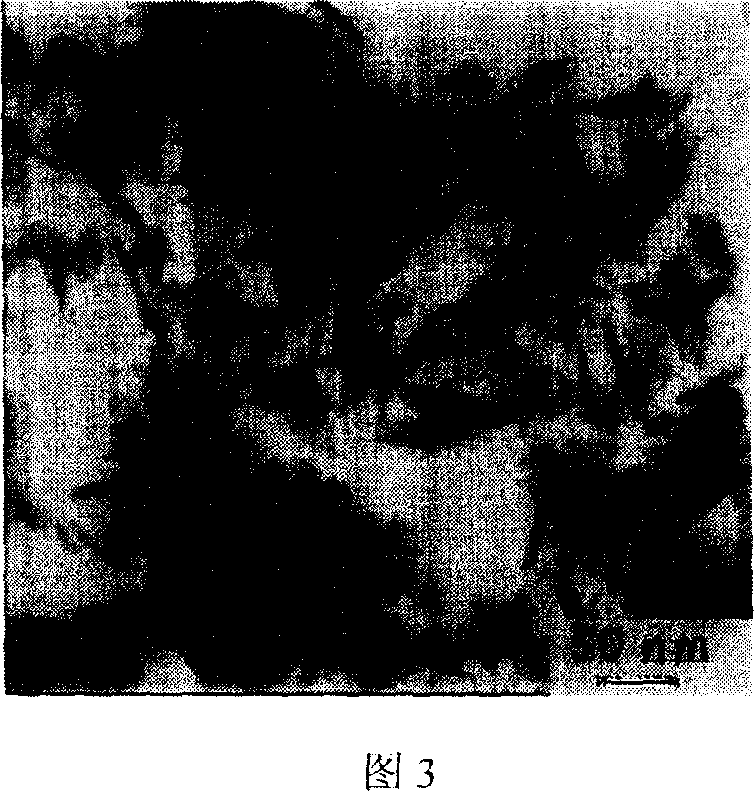

[0030]Embodiment 3, the preparation steps of nickel sulfide nanorods are: (1) Preparation of nickel hexadecyl sulfonate: same as in embodiment 2. (2) The preparation method of the ionic liquid is the same as in Example 2. (3) Preparation of NiS nanorods: Add 0.03g of nickel hexadecyl sulfonate and 3mL of 1-hexyl-3-methylimidazolium hexafluorophosphate ionic liquid into a 50mL single-necked bottle, and stir gently with a magnetic stirrer , so that nickel hexadecyl sulfonate is evenly dispersed in the ionic liquid, put the one-mouth bottle into the oil bath, and slowly heat the oil bath from room temperature to 210 ° C, while magnetic stirring, keep for 30 minutes, and then take out the one-mouth bottle , after the solution was cooled to room temperature, the product was separated by centrifugation, the separated product was washed 5 times with acetone, and then dried at room temperature to obtain a shuttle-shaped nickel sulfide nanorod.

[0031] As shown in FIG. 4 , the analys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com