Stable glassy state powder formulations

a powder formulation and glassy state technology, applied in the field of pharmaceutical compositions, can solve the problems of powder particles agglomeration and hard cakes, valve clogging, and various disadvantages of dry powder aerosol systems, and achieve and stable dispersibility over time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

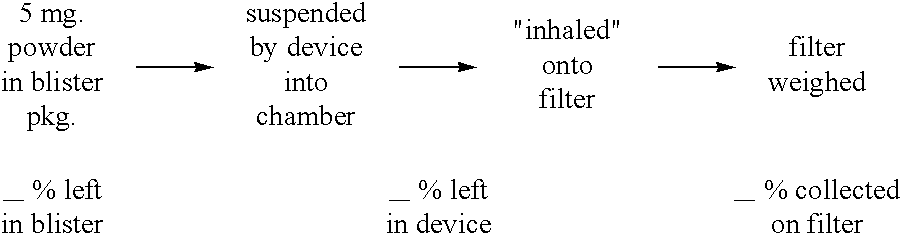

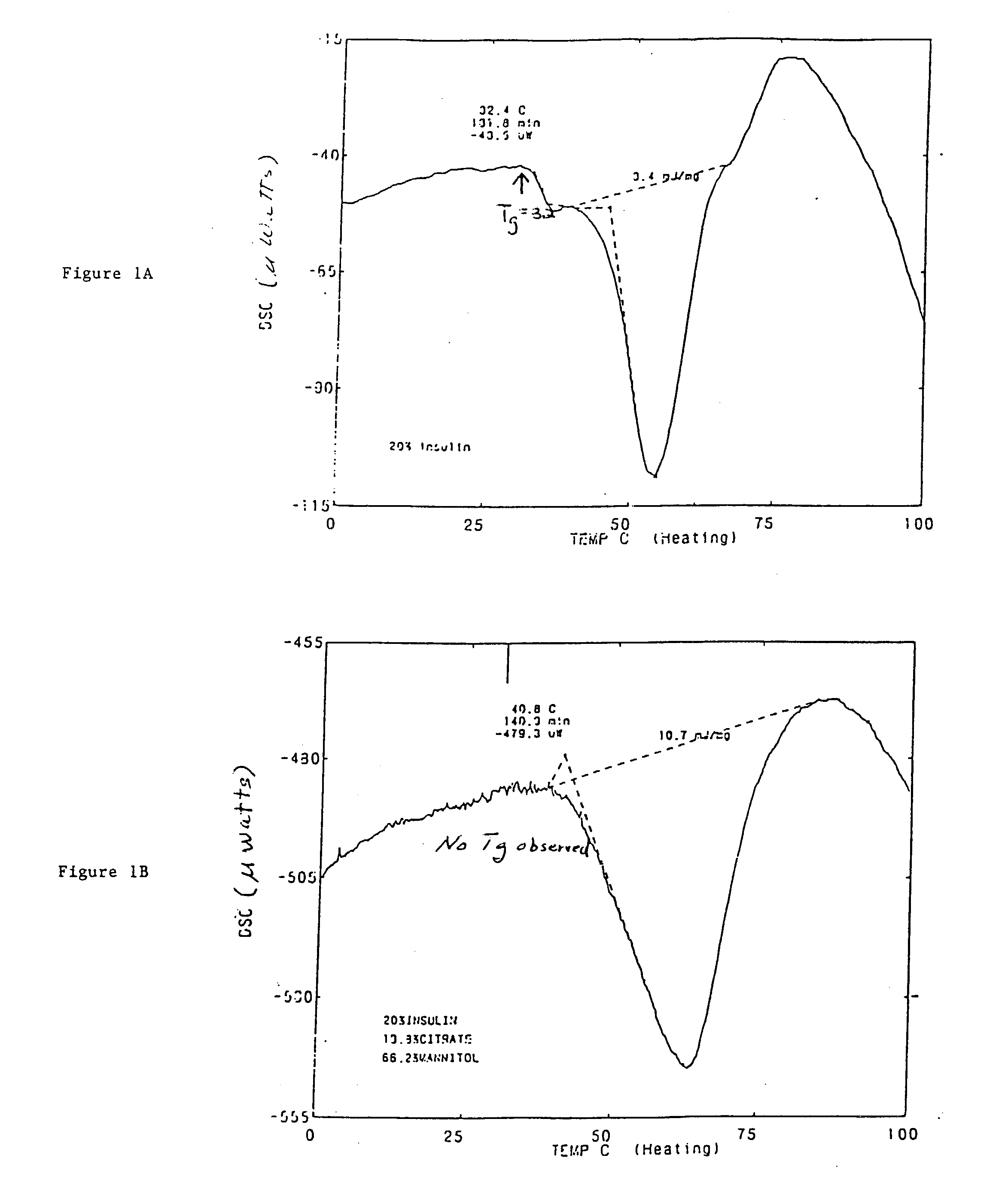

[0104] This example describes a 20% insulin formulation for which the difference between T.sub.g and T.sub.s is less than 10.degree. C. This resulted in a formulation that, although chemically stable, did not have stable dispersibility over the desired shelf life of the product at standard recommended storage temperature (T.sub.s) testing conditions.

[0105] A 20% insulin aerosol formulation was obtained by preparing a solution of human zinc insulin, mannitol, sodium citrate dihydrate, and citric acid monohydrate. Bulk crystalline human zinc insulin, obtained from Eli Lilly and Company, Indianapolis, Ind., and U.S.P. grade excipients were used. The solution contained 1.5 mg insulin, 4.96 mg mannitol, 1.04 mg citrate buffer (sodium citrate and citric acid) per milliliter of deionized water for a total solids concentration of 7.5 mg / mL at pH 6.7. A dry powder was prepared by spray-drying the aqueous solution using a Buchi Laboratory Spray Dryer--Model 190 under the following conditions:...

example 2

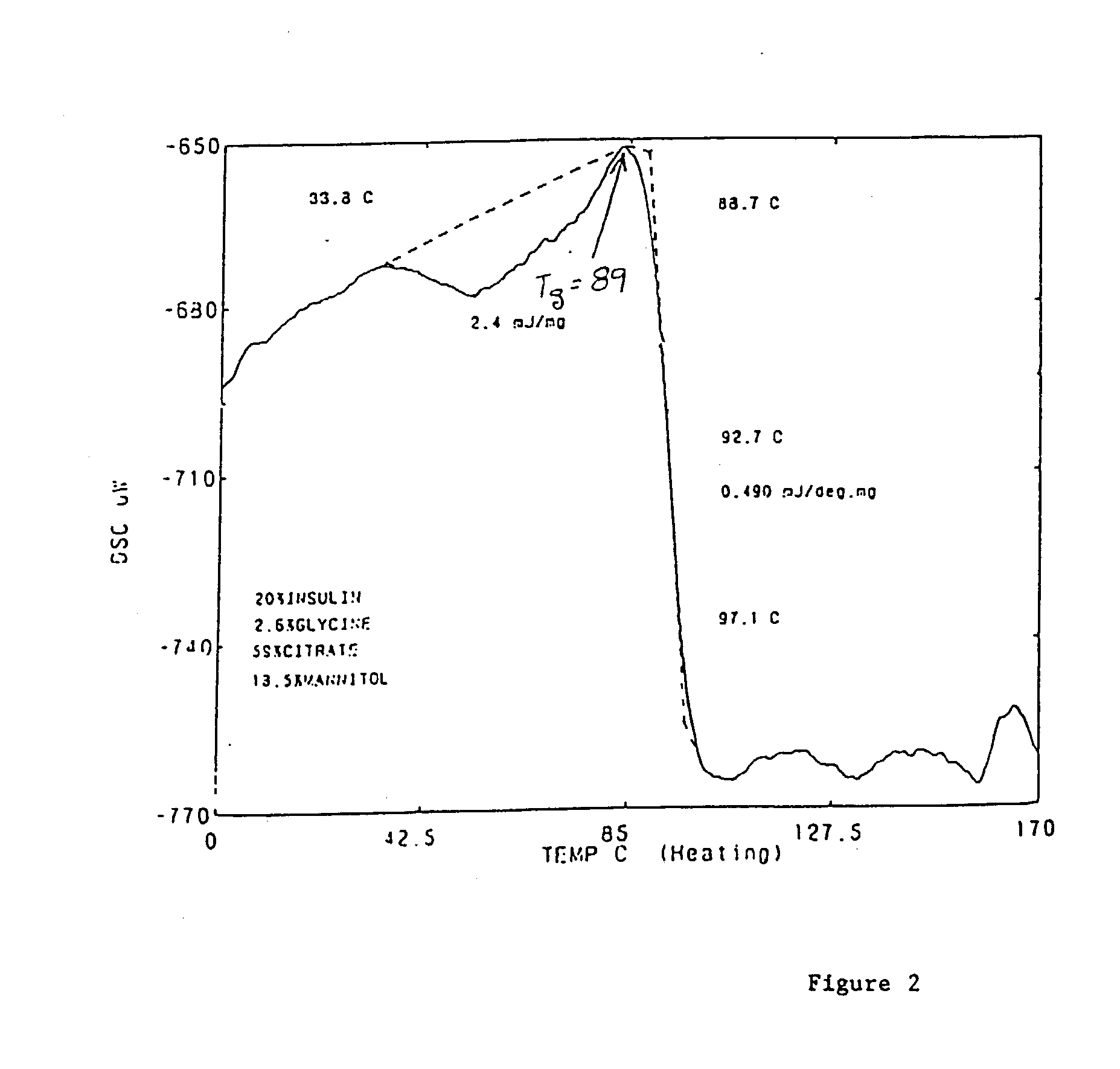

[0114] This example sets forth a 20% insulin composition of this invention that maintained protein integrity and aerosol stability after storage at 30.degree. C., 40.degree. C., 50.degree. C., and temperature cycling at 2 to 37.degree. C.

[0115] A 20% insulin aerosol formulation was obtained by preparing a solution of human zinc insulin, mannitol, sodium citrate dihydrate, and citric acid monohydrate. Bulk crystalline human zinc insulin, obtained from Eli Lilly and Company, Indianapolis, Ind., and U.S.P. grade excipients were used. The solution contained 2.0 mg insulin, 1.82 mg mannitol, 5.91 mg sodium citrate, 0.006 mg citric acid, and 0.26 mg glycine per milliliter of deionized water for a total solids concentration of 10.0 mg / mL at pH 7.3. Dry powders were prepared by spray-drying the aqueous solution using a Buchi Laboratory Spray Dryer under the following conditions:

5 Temperature of aqueous solution 2-8.degree. C. Inlet temperature 128-130.degree. C. Outlet temperature 85-88.deg...

example 3

[0126] This example sets forth a 60% Insulin composition that maintained protein integrity and aerosol stability after storage at 30.degree. C., 40.degree. C., 50.degree. C., and temperature cycling at 2 to 37.degree. C.

[0127] A 60% insulin aerosol formulation was obtained by preparing a solution of human zinc insulin, mannitol, sodium citrate dihydrate, and citric acid monohydrate. Bulk crystalline human zinc insulin, obtained from Eli Lilly and Company, Indianapolis, Ind., and U.S.P. grade excipients were used. The solution contained 7.50 mg insulin, 1.27 mg mannitol, 3.38 mg sodium citrate, 0.026 mg sodium hydroxide, and 0.32 mg glycine per milliliter of deionized water for a total solids concentration of 12.5 mg / mL at pH 7.3.

[0128] A Niro Spray Dryer was used to prepare the dry powder using the following conditions:

8 Temperature of aqueous solution 2-8.degree. C. Atomizer chilling water return 2-6.degree. C. Inlet temperature 143-147.degree. C. Outlet temperature 79-81.degree. C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com