Composite dielectric material, composite dielectric substrate, prepreg, coated metal foil, molded sheet, composite magnetic substrate, substrate, double side metal foil-clad substrate, flame retardant substrate, polyvinylbenzyl ether resin composition, and method for preparing thermosetting polyvinylbenzyl ether resin composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1-1

[0362] First, a ceramic powder and a polyvinylbenzyl ether compound were mixed in accordance with a formulation as shown in Tables 3 and 4, thoroughly milled in toluene and dried at 90 to 120° C. for about 2 hours. This was ground into a powder of the ceramic powder and polyvinylbenzyl ether compound mixture, having a mean particle size of 50 to 1,000 μm. The powder was placed in a mold of 6.5 cm×5 cm and cured at 120 to 200° C. for 2 hours, obtaining the end composition.

[0363] The ceramic powders used were MgTiO3 (mean particle size 5 μm), Ba2(Ti,Sn)9O20 base (mean particle size 10 μm), Bi2O3—BaO—Nd2O3—TiO2 base (mean particle size 5 μm), CaTiO3 (mean particle size 0.5 μm), and SrTiO3 (mean particle size 0.5 μm) powders.

[0364] The polyvinylbenzyl ether compound (VB) used was of the formula (1) wherein R1 is methyl, R2 is benzyl, R3 is a mixture of hydrogen and vinylbenzyl in a molar ratio of 0:100, and n=3.

[0365] From each of the compositions, a rod sample of about 1.0 mm square...

example 1-2

[0369] Compositions were prepared as in Example 1-1 by mixing the ceramic powder and the polyvinylbenzyl ether compound both used in Example 1-1 in the following combination.

[0370] Ba2(Ti,Sn)9O20 base ceramic powder (60 vol %)+polyvinylbenzyl ether compound (40 vol %) (the same as sample No. 17 in Example 1-1).

[0371] Bi2O3—BaO—Nd2O3—TiO2 base ceramic powder (60 vol %)+polyvinylbenzyl ether compound (40 vol %) (the same as sample No. 27 in Example 1-1).

[0372] SrTiO3 ceramic powder (60 vol %)+polyvinylbenzyl ether compound (40 vol %) (the same as sample No. 43 in Example 1-1).

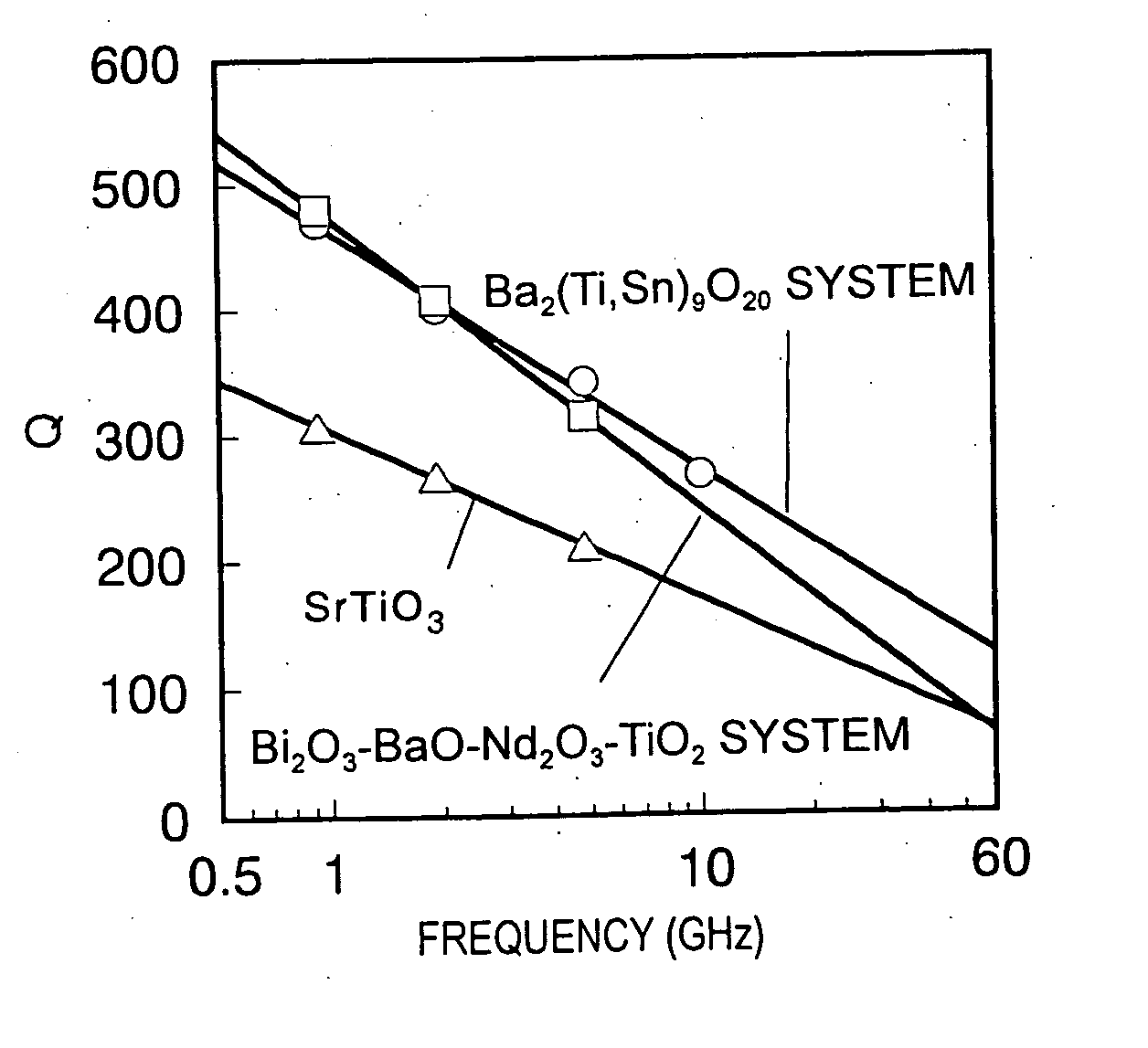

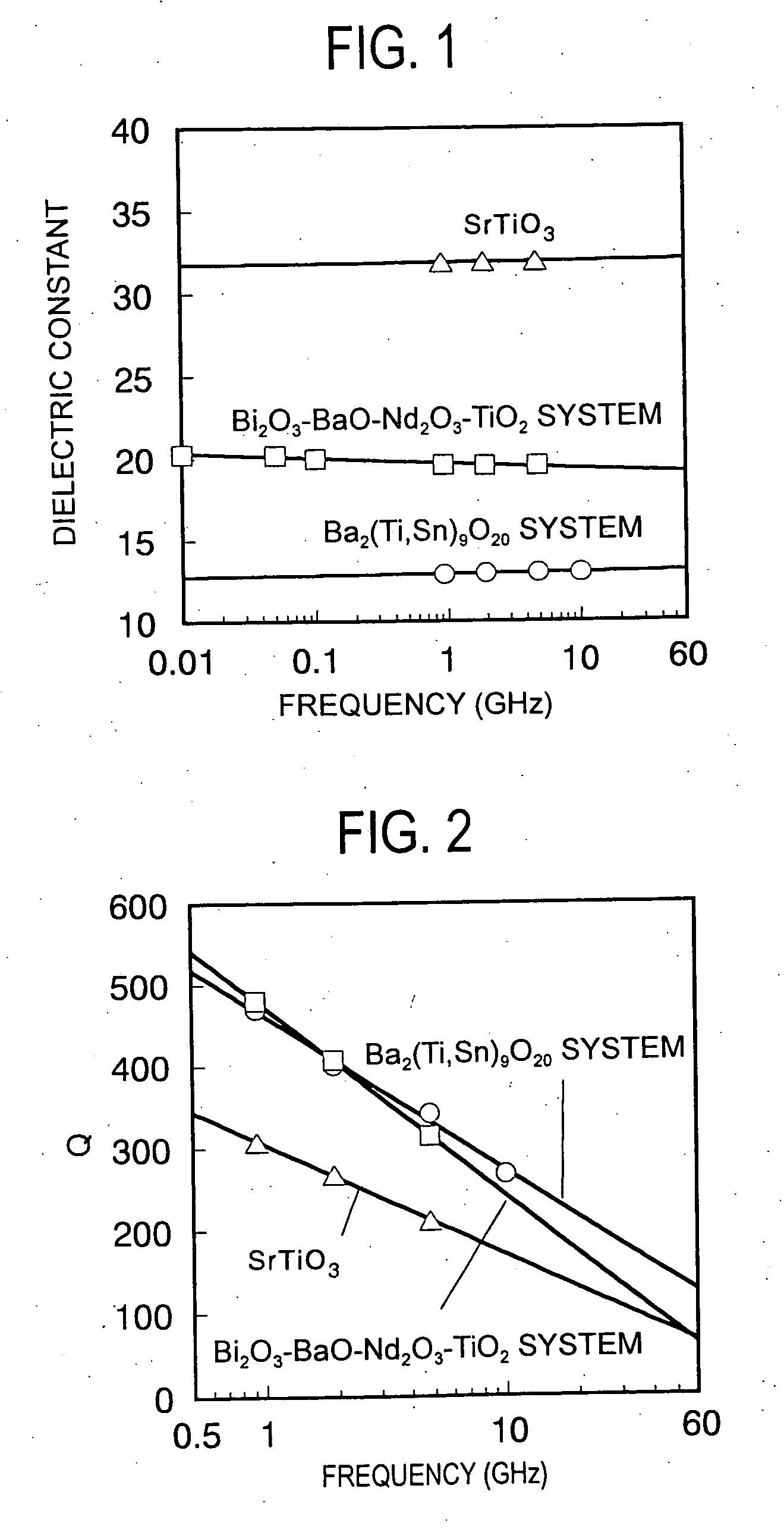

[0373] These samples were measured for dielectric constant at a frequency of 0.01 to 10 GHz, with the results being plotted in the graph of FIG. 1. The Q of the samples at a frequency of 1 to 10 GHz is shown in FIG. 2. These measurements were the same as in Example 1-1. A dielectric constant at a frequency of less than 100 MHz (0.1 GHz) was measured using an impedance / material analyzer 4291A by Hewlett Packar...

example 2-1

[0375] First, a ceramic powder and a polyvinylbenzyl ether compound were mixed in accordance with a formulation as shown in Table 5, thoroughly milled in toluene and dried at 90 to 120° C. for about 2 hours. This was ground into a powder of the ceramic powder and polyvinylbenzyl ether compound mixture, having a mean particle size of 50 to 1,000 μm. The mixture powder was placed in a mold of 6.5 cm×5 cm and cured at 120 to 200° C. for 2 hours, obtaining the end composition.

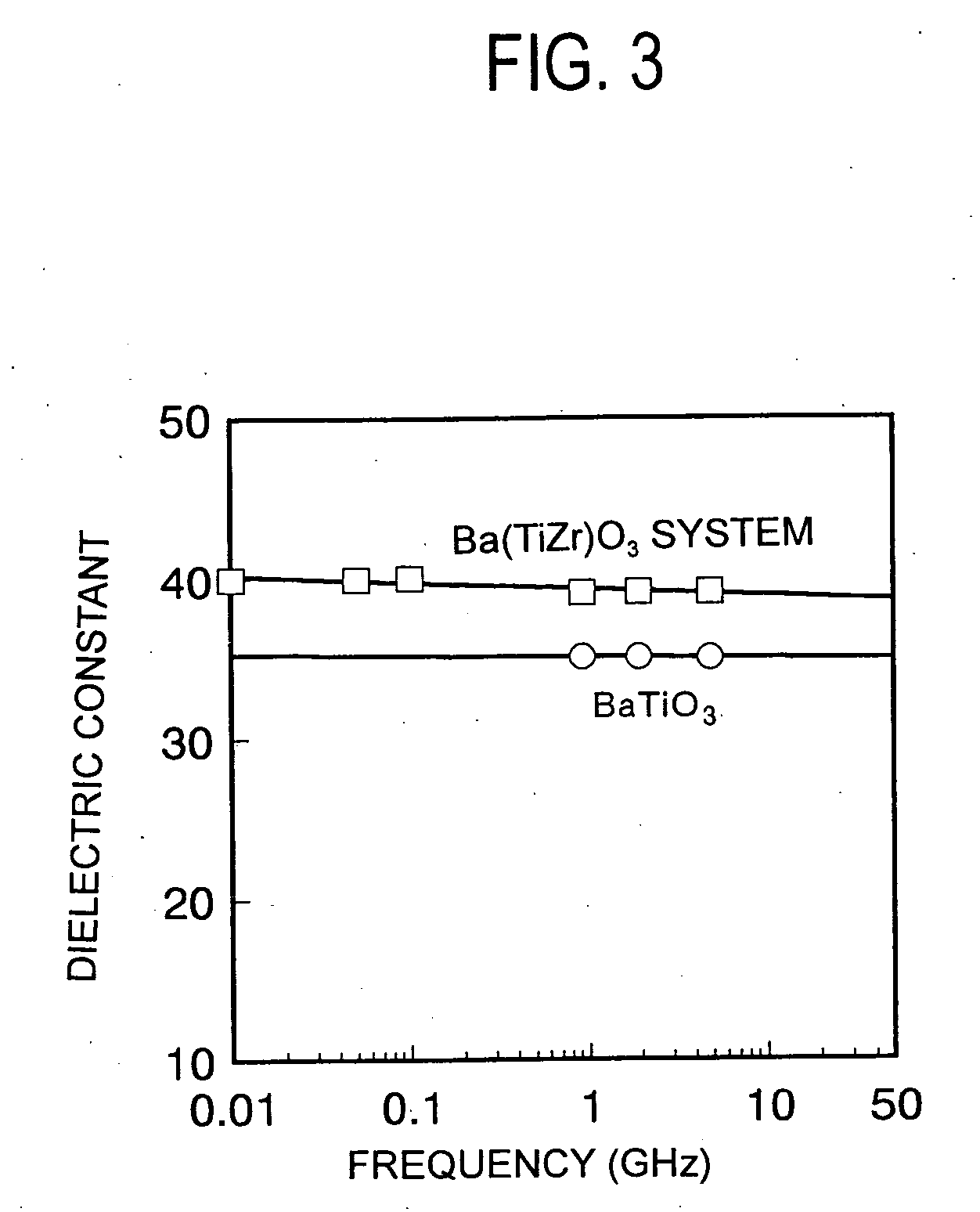

[0376] The ceramic powders used were BaTiO3 (mean particle size 0.5 μm) and Ba(Ti,Zr)O3 base (mean particle size 5 μm) powders.

[0377] The polyvinylbenzyl ether compound (VB) used was of the formula (1) wherein R1 is methyl, R2 is benzyl, R3 is a mixture of hydrogen and vinylbenzyl in a molar ratio of 0:100, and n=3.

[0378] From each of the compositions, a rod sample of about 1.0 mm square by about 6.5 mm long was formed and measured for dielectric constant at 2 GHz by the cavity resonator perturbation method usin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com