Method and composition for the triggered release of polymer-degrading agents for oil field use

a technology of degrading agent and oil field, applied in the field of compositions, can solve the problems of filter cake being a significant impediment, not being easily or completely flushed out of formation, filter cake sealing, etc., and achieve the effect of preventing screen damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

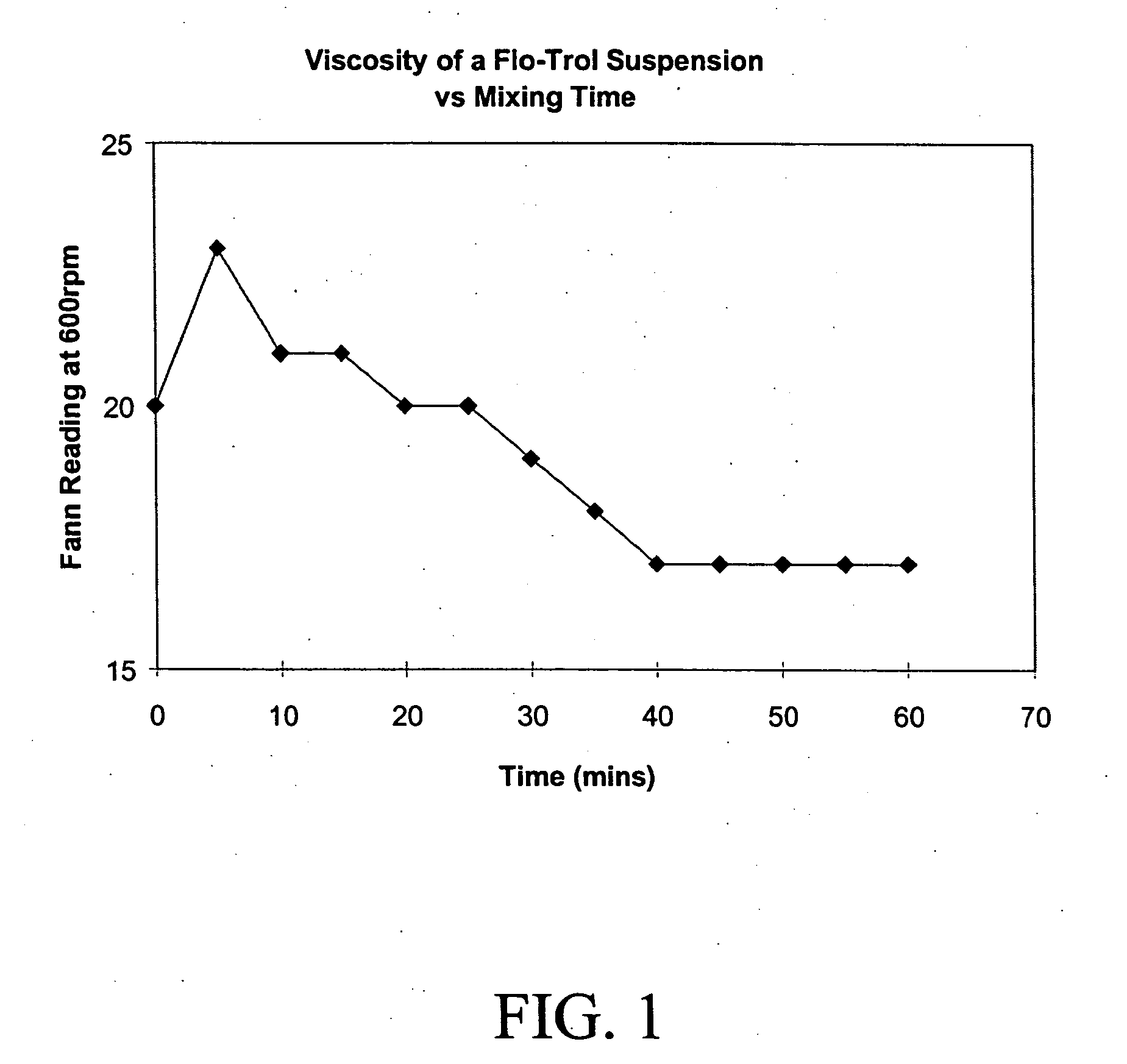

example 1

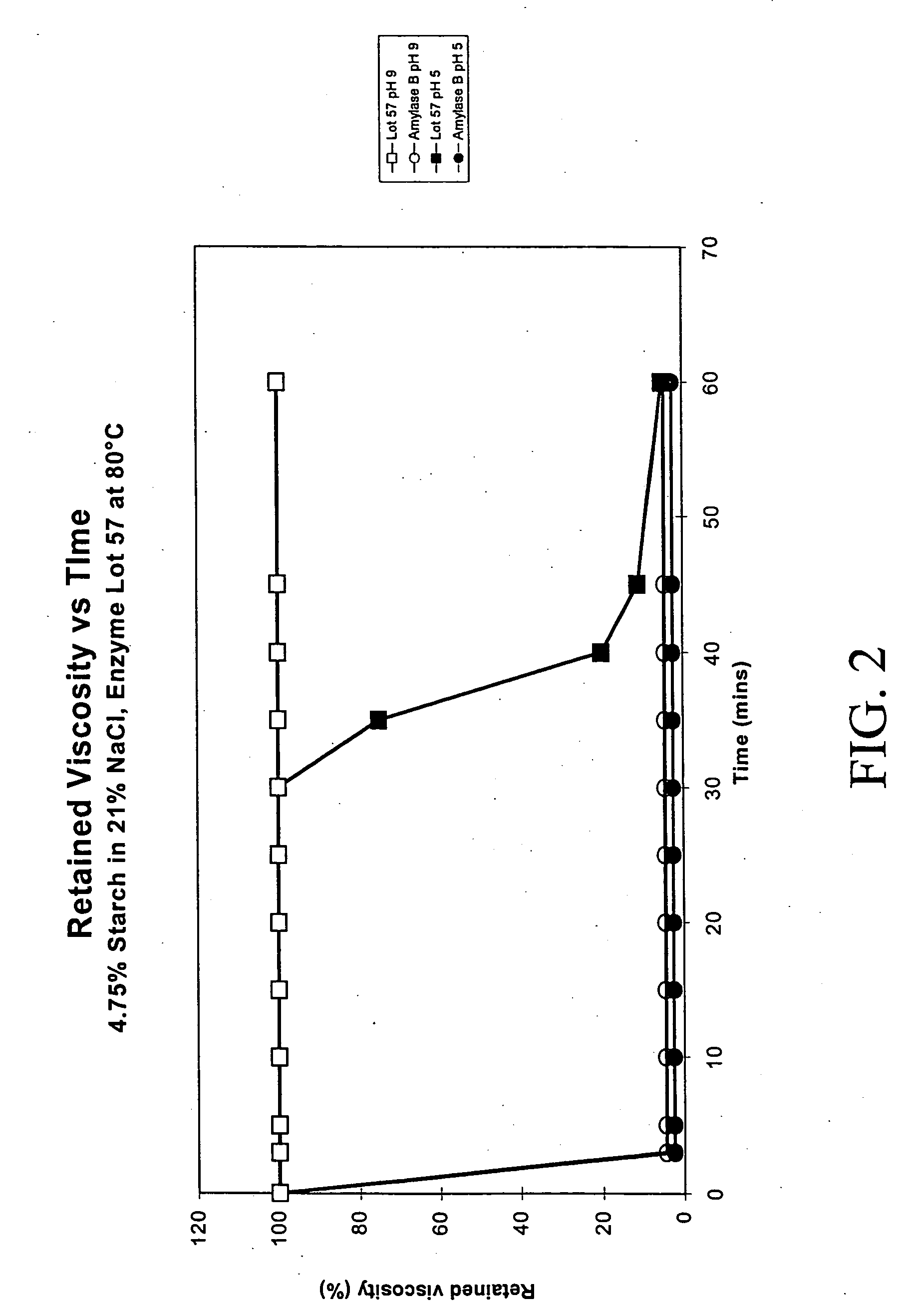

[0144] Employing the above-described procedures, the inventors have developed an encapsulated starch-degrading enzyme that is inactive at pH 10 and higher but releases active enzyme at pH 8 and lower. A choice was made among several alpha-amylases offered by Novo-Nordisk Pharmaceutical Company, selecting one that has the highest activity at the temperature and pH expected to be encountered for the present examples. The enzyme solution was then lyophylized to remove water and made suitable for the application of an encapsulation technology described by Ciba in U.S. Pat. Nos. 5,492,646; 5,460,817 and 5,324,445 and in PCT publication WO 97 / 24178, the disclosures of which are incorporated herein by reference.

[0145] Encapsulation was accomplished. using a suitable co-polymer of styrene (when preparing sample lots #57 and #63) or methyl methacrylate (when preparing sample #37) and t-butyl amino ethyl methacrylate was synthesized by isothermal solution polymerization in an organic solvent...

example 2

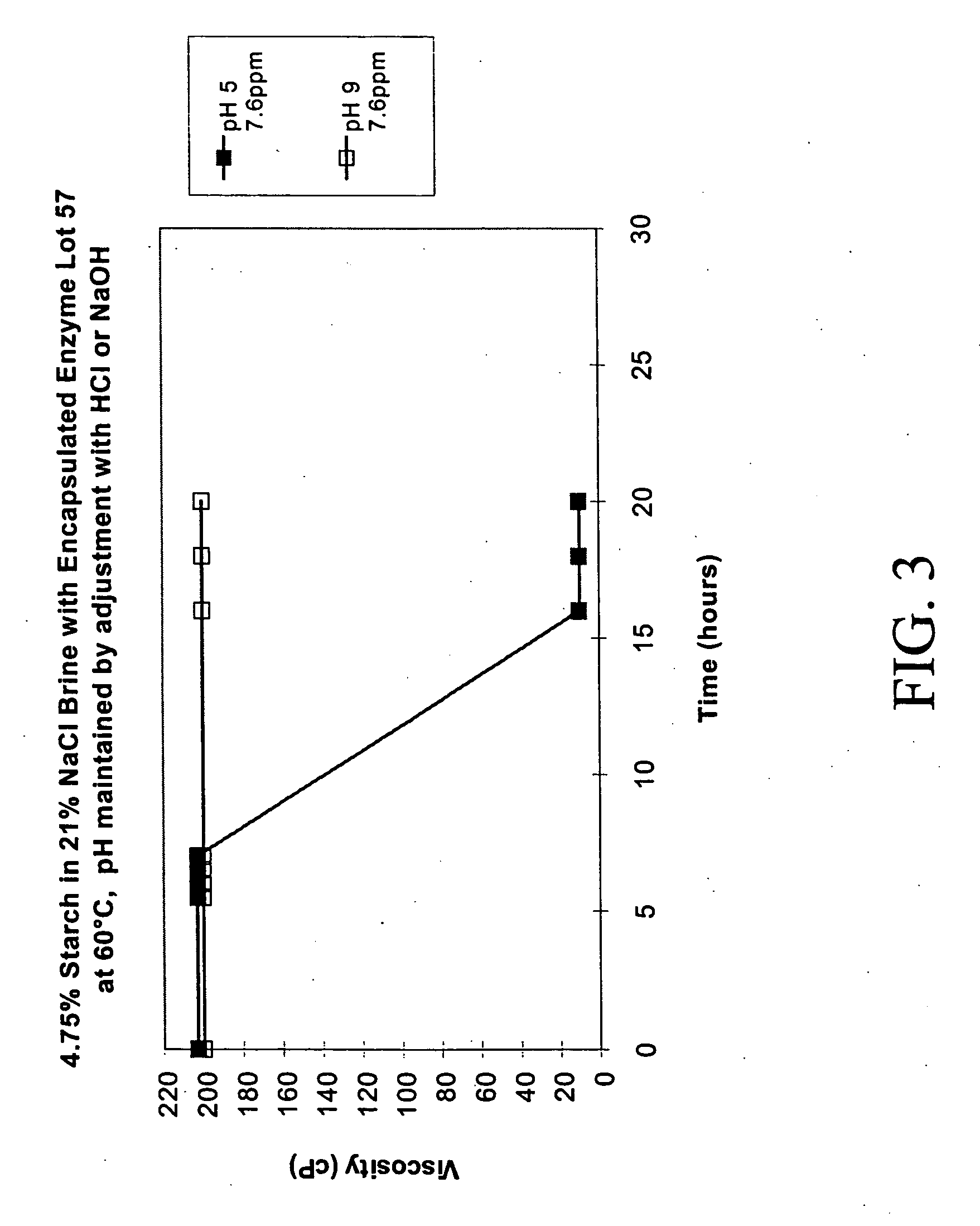

[0159] Four exemplary reservoir drilling fluids containing the encapsulated α-Amylase enzyme, encapsulated as described above, were prepared and it was demonstrated that the incorporation into finished reservoir drilling fluid without release of enzymes under operating conditions is feasible. The composition of the four reservoir drilling fluid formulations numbered 1 to 4 are reported in Table IV. Fluids were prepared using standard oilfield products and procedures. References to numbered fluids in the following tables refer to this chart.

[0160] Fluid 1 shows good rheology and fluid loss control as shown in Table V. When treated with encapsulated enzyme and maintained at pH 10, rheology and fluid loss properties are essentially unchanged. Treatment with neat enzyme results in loss of viscosity and an increase in API fluid loss. When the stable pH 10 fluid was adjusted to pH 5 with phosphoric acid, rheology and fluid loss go to nearly the levels of the fluid treated with neat enzym...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com