Processes and systems for formation of high voltage, anodic oxide on a valve metal anode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

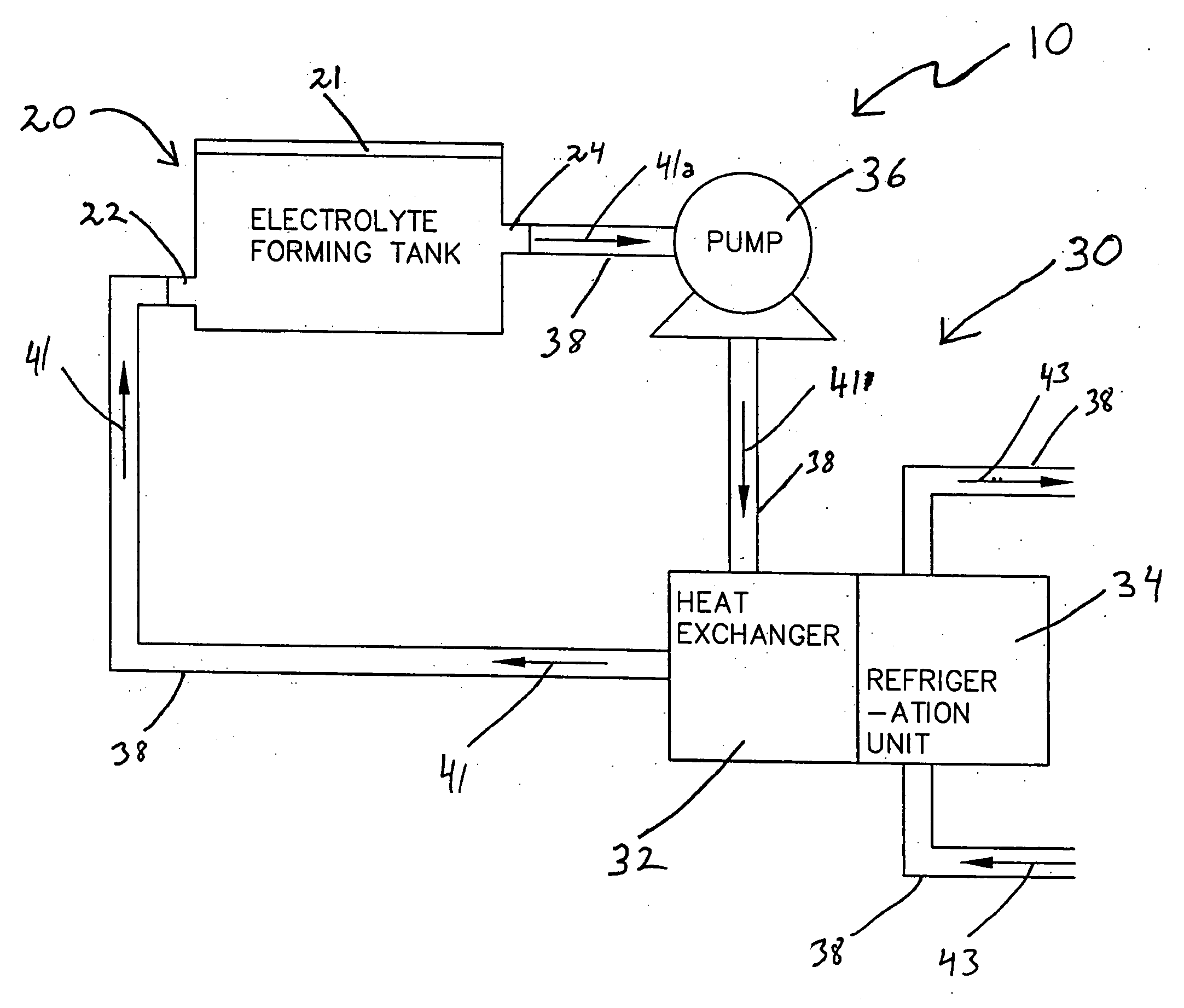

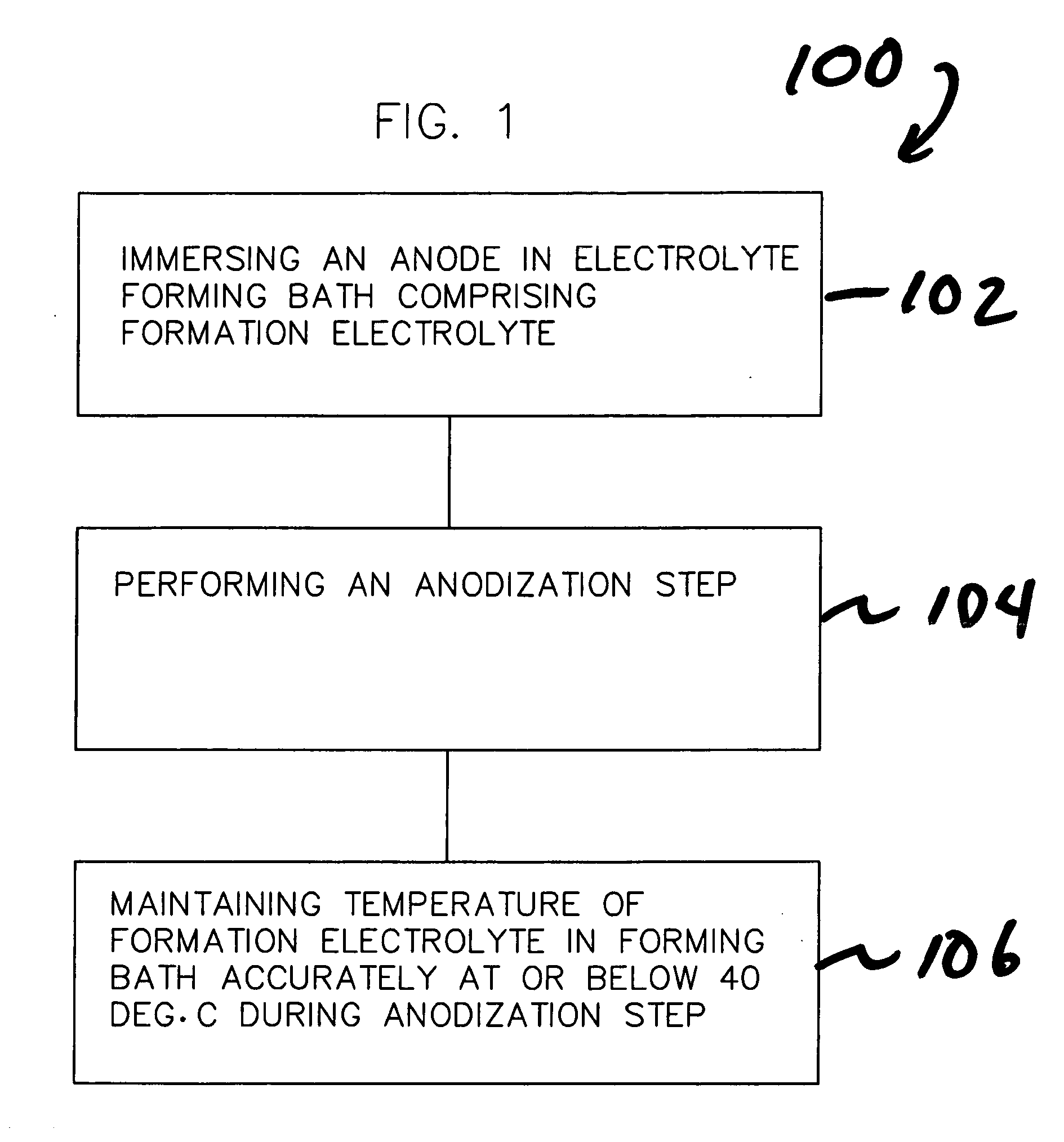

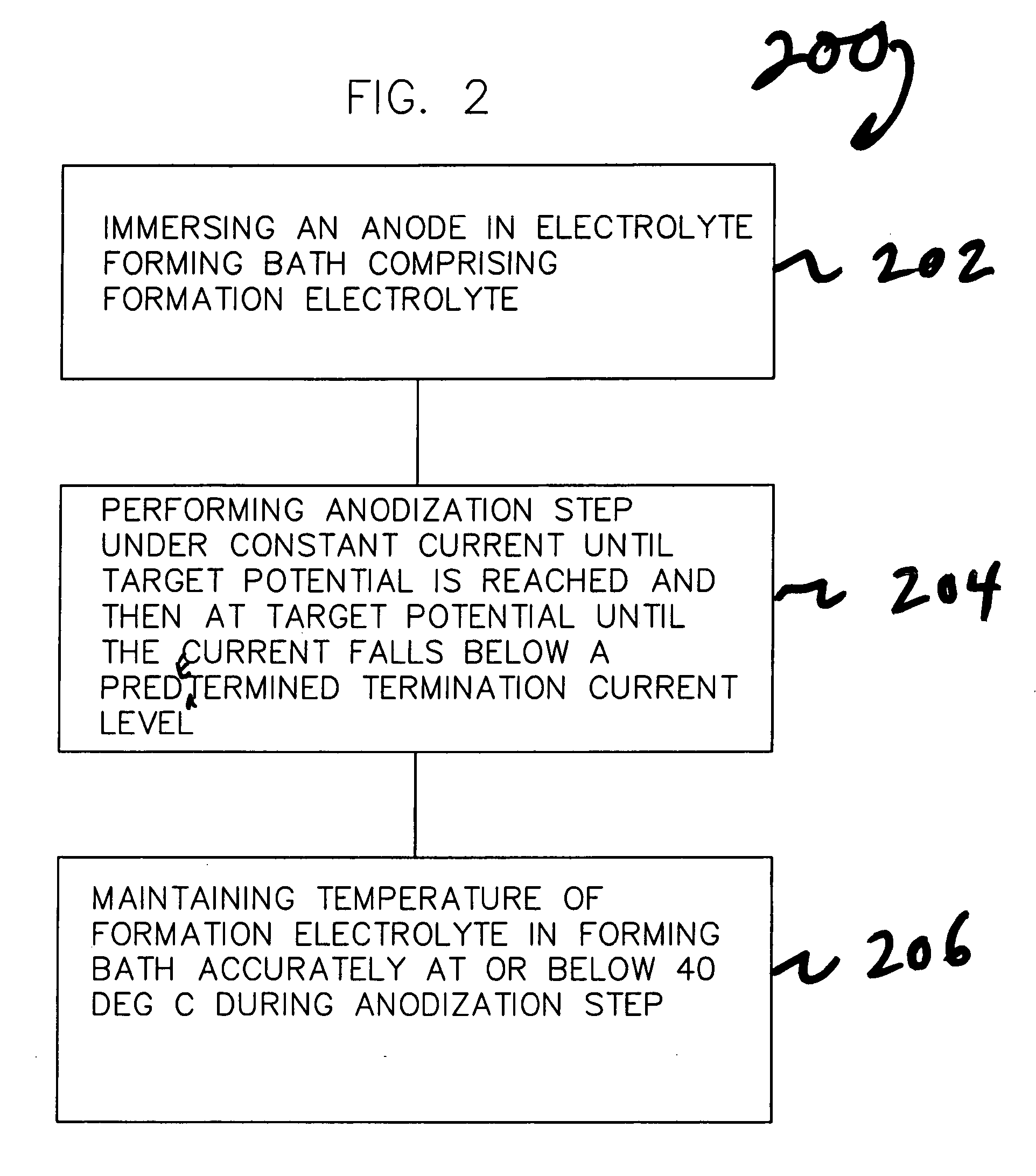

Method used

Image

Examples

example 1

[0081] A set of 8 capacitors were formed with the pulsed formation technique depicted in FIG. 8 and discussed earlier herein. Anodes 1 through 4 were processed in a system without active temperature control, which allowed the bath temperature to fluctuate or climb up to 40° C. at the time of maximum power dissipation, a traditional method. Anodes 5 through 8 were processed in a system with accurate temperature control of the formation bath, keeping the temperature constant at 18° C., a method according to the invention. Processing conditions were otherwise the same for all 8 electrodes, with the exception of the use of active temperature control according to the invention in the processing of Anodes 5-8 to accurately maintain the temperature of the formation electrolyte at 18° C. The target potential was 260 V, initial formation current was 275 mA for four anodes. Formation frequency was about 0.2 mHz with a duty cycle between 95% and 75% depending on the power dissipation. Table 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com