Thin films of ferroelectric materials and a method for preparing same

a technology of ferroelectric materials and thin films, which is applied in the direction of metallic material coating process, liquid/solution decomposition chemical coating, coating, etc., can solve the problems of inability to randomly orientated pzn-pt films with a very low pzn composition, and inability to achieve optimal characteristics of commercial applications. , to achieve the effect of high dielectric constant, excellent piezoelectric properties and strong ferrolectriqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

PZN-PT Thin Films on LAO Substrate

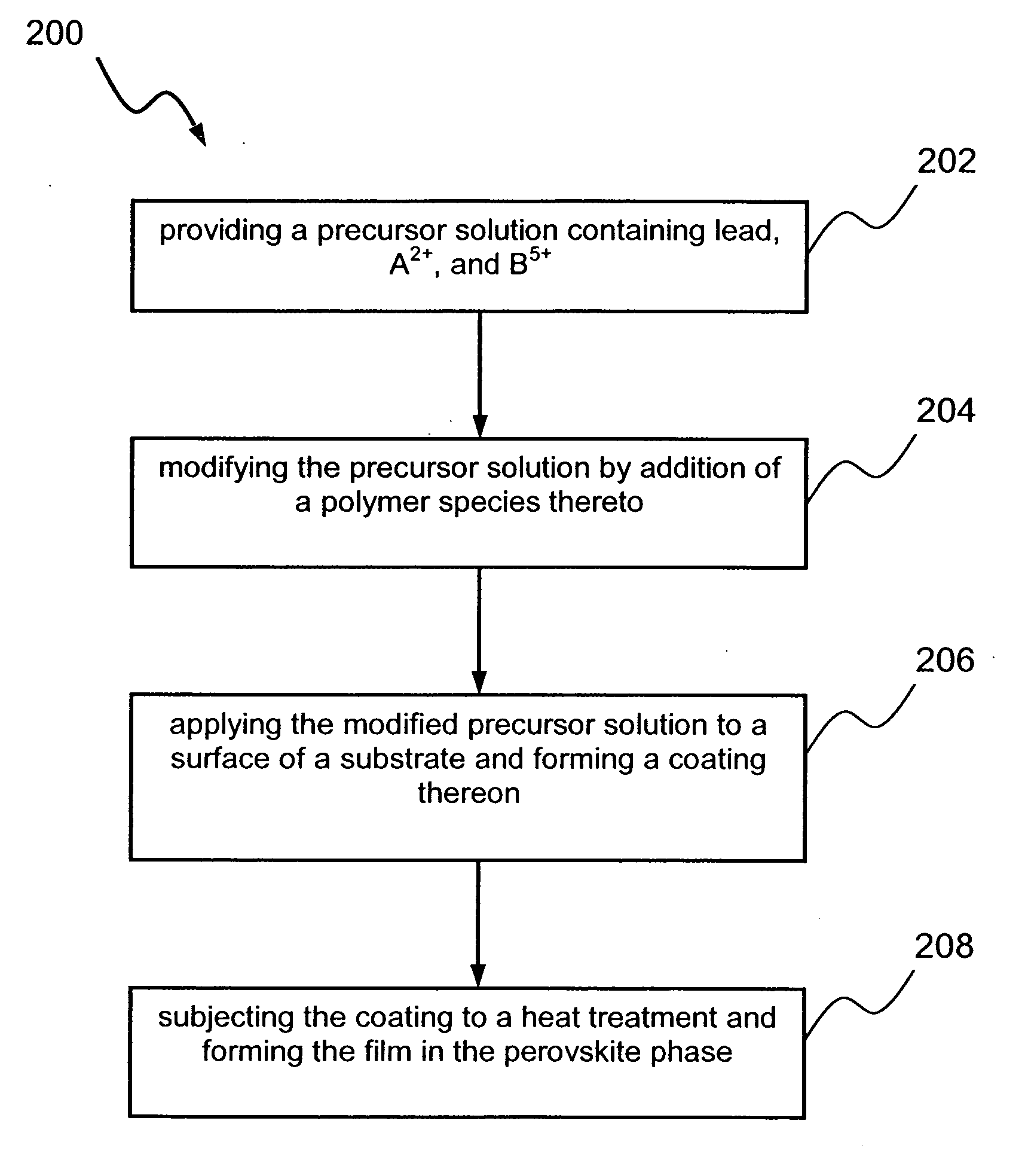

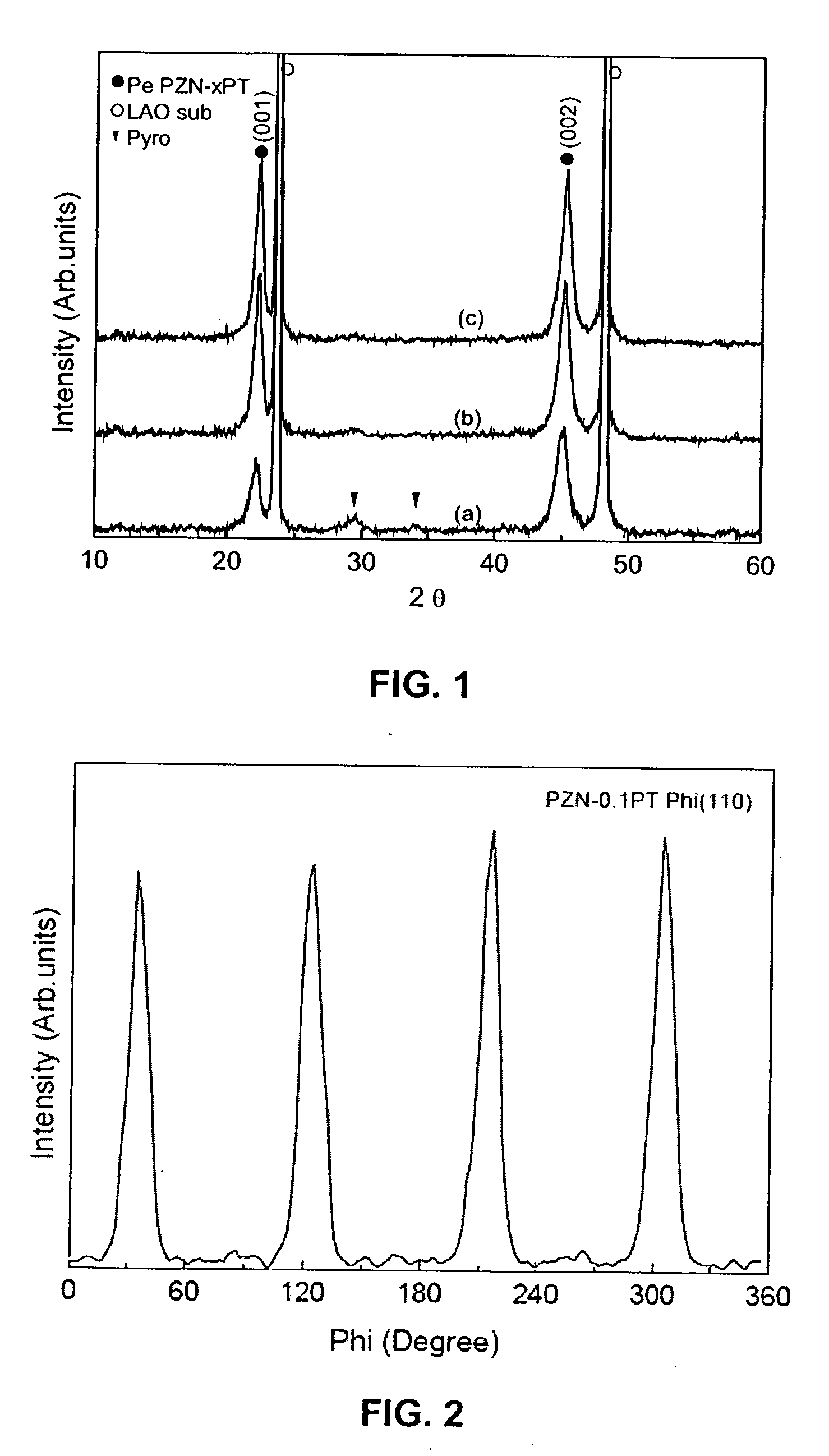

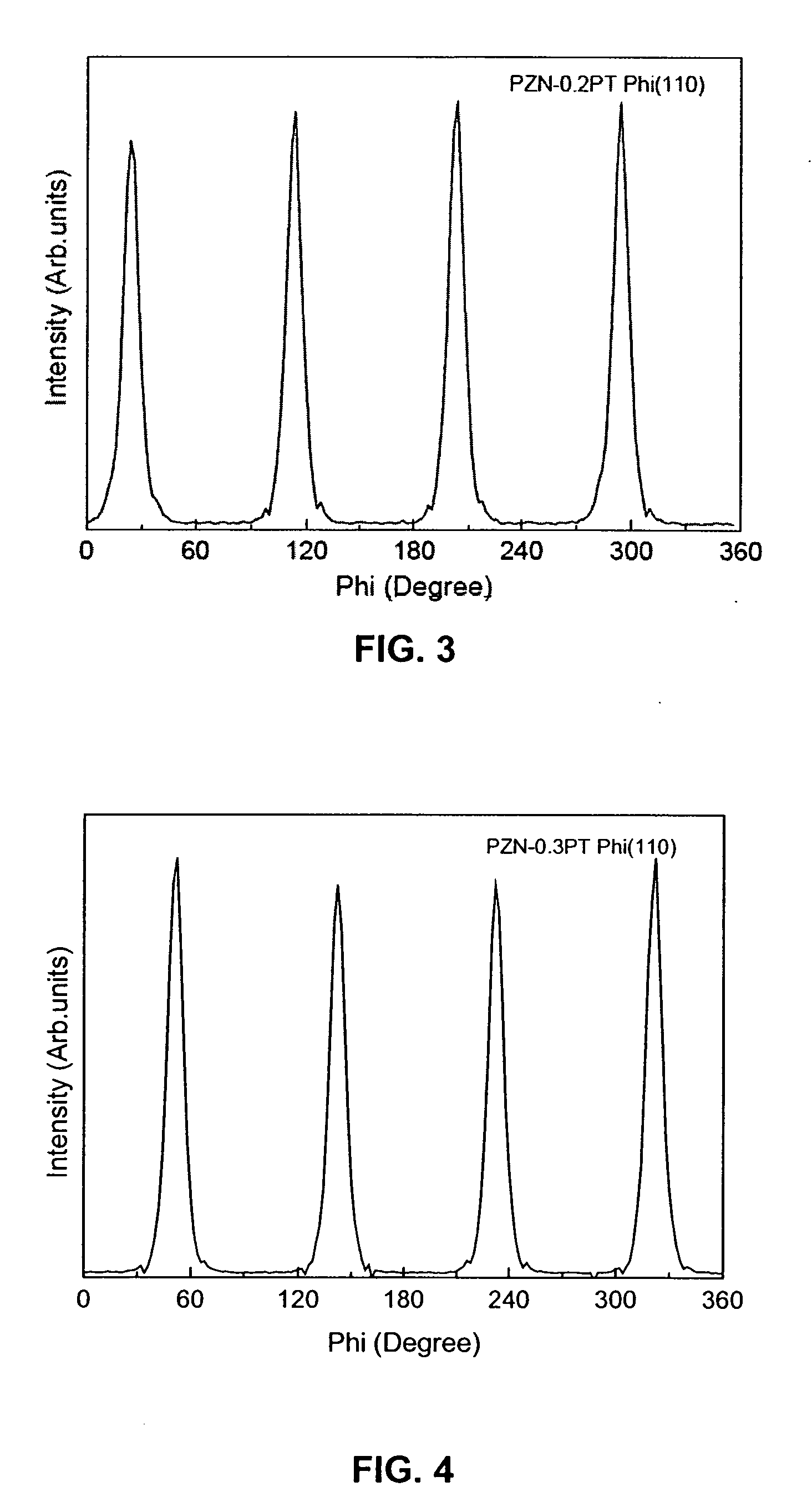

[0118] In this example, the preparation of epitaxial ferroelectric (1-x)Pb(Zn1 / 3Nb2 / 3)O3-xPbTiO3 (PZN-xPT) thin films on a perovskite LaAlO3 (LAO) single crystal substrate is described.

[0119] The PZN precursor solution was prepared by first dissolving zinc acetate trihydrate (0.00500 mol) in 2-methoxyethanol (2-MOE) at 80° C. Subsequently, niobium isopropoxide (0.01000 mol) was added to the solution with mechanical stirring or reluxing. The solution was allowed to clarify then cooled to room temperature. A separate solution of lead acetate trihydrate (0.01725 mol) in 2-MOE was prepared at 115° C. and the solution was stirred for 15 minutes. The two solutions were then mixed at room temperature and diluted with 2-MOE to obtain a concentration of 0.3 M.

[0120] The PT precursor solution was prepared by dissolving lead acetate trihydrate (0.03450 mol) in 2-MOE at 115° C. A separate solution of titanium isopropoxide (0.0300 mol) in 2-MOE was prepared a...

example 3

PZN-XPT Thin Films on Perovskite Conductive Oxide Layers on Silicon

[0143] Epitaxial PZN-XPT thin films can also be prepared on a conductive oxide layer which is expitaxially grown on some substrates whose structures or lattice parameters do not match perovskite PZN-xPT thin film through introduction of appropriate buffer layers. The perovskite conductive thin films include LaxSr1-xMnO3, LaxCa1-xFeO3, LaNiO3, SrRuO3, LaxSr1-xCoO3, LaxSr1-xFeO3, etc.

[0144] In Example 3, epitaxial yttria-stabilized zirconia (YSZ), YBa2Cu3o7-δ(YBCO), and La0.7Sr0.3MnO3 (LSMO) layers are successively grown on (100)-oriented single crystal silicon substrate, followed by deposition of an epitaxial PZN-xPT thin film. The epitaxial deposition of the conductive LSMO and its buffer layers can be achieved by using any existing methods of epitaxy and, notably, vapor phase epitaxy, metal organic chemical vapor deposition (MOCVD), molecular beam epitaxy (MBE), metal organic molecular beam epitaxy (MOMBE) or liqu...

example 5

(1-x)Pb((Zn,Mg)⅓Nb⅔)03-xPbTiO3(PZMN-xPT) Thin Films on LSMO / LAO

[0159] An epitaxial La0.7Sr0.3MnO3 (LSMO) thin film was coated on a LAO substrate as bottom electrode by pulsed laser deposition (PLD) method. The processing conditions were the same as described in Example 3, resulting in a conductivity of about 3×10−4 Ω·cm.

[0160] A PZMN-xPT thin film was then coated using the same PZMN-PT solution with 60 wt % PEG200 additive, which was prepared according to the method in Example 4, on the top of the LSMO film. The spin coating was conducted at 5000 rpm for 30 seconds in a clean room. Each coating layer was dried at 100° C. for 2 minutes, followed by pyrolysis at 430° C. for 5 minutes and pre-annealing at 580° C. for 10 minutes. A thickness of 1 um was obtained by repeating the process. Finally, the film was annealed at 700° C. for 10 minutes.

[0161]FIG. 16 (a) and (b) show the XRD patterns of the 0.77(0.6PZN-0.4PMN)-0.23PT thin films grown on the LSMO-coated LAO substrates, annealed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Digital information | aaaaa | aaaaa |

| Digital information | aaaaa | aaaaa |

| Percent by mole | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com