Process for producing extremely flat microcrystalline diamond thin film by laser ablation method

a laser ablation and diamond thin film technology, applied in the direction of crystal growth process, solid state diffusion coating, polycrystalline material growth, etc., can solve the problem of future coating and electronic device application difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

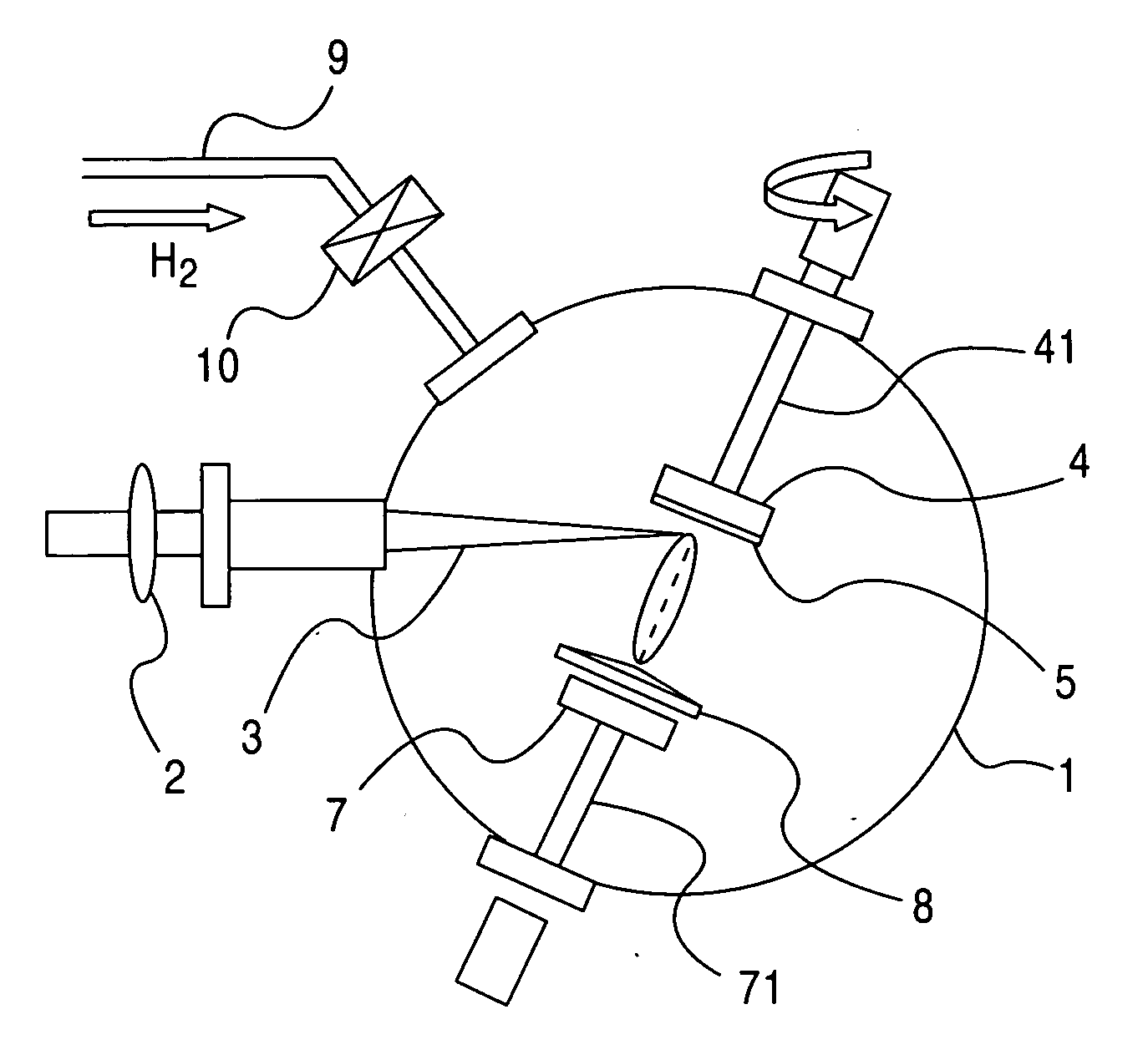

Method used

Image

Examples

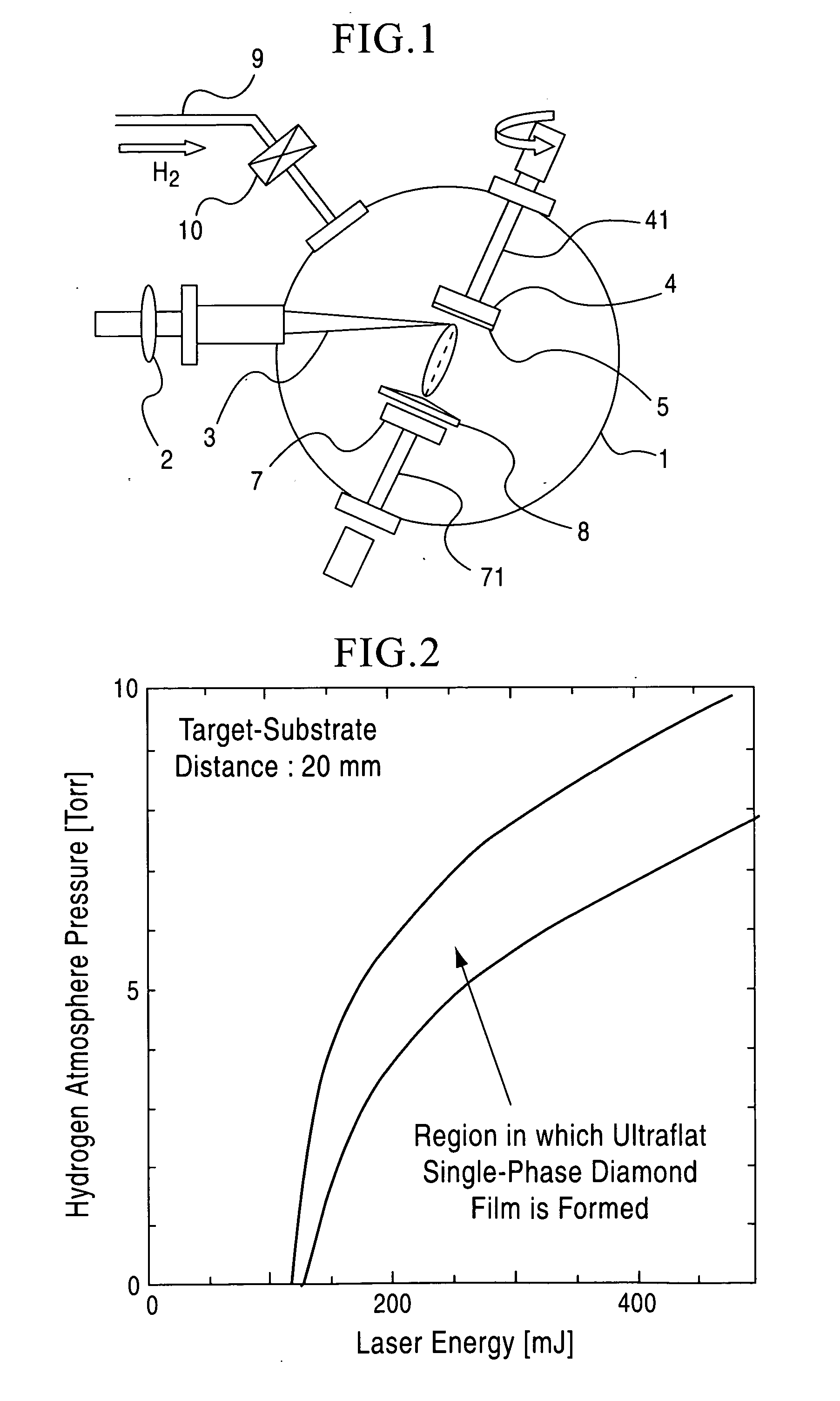

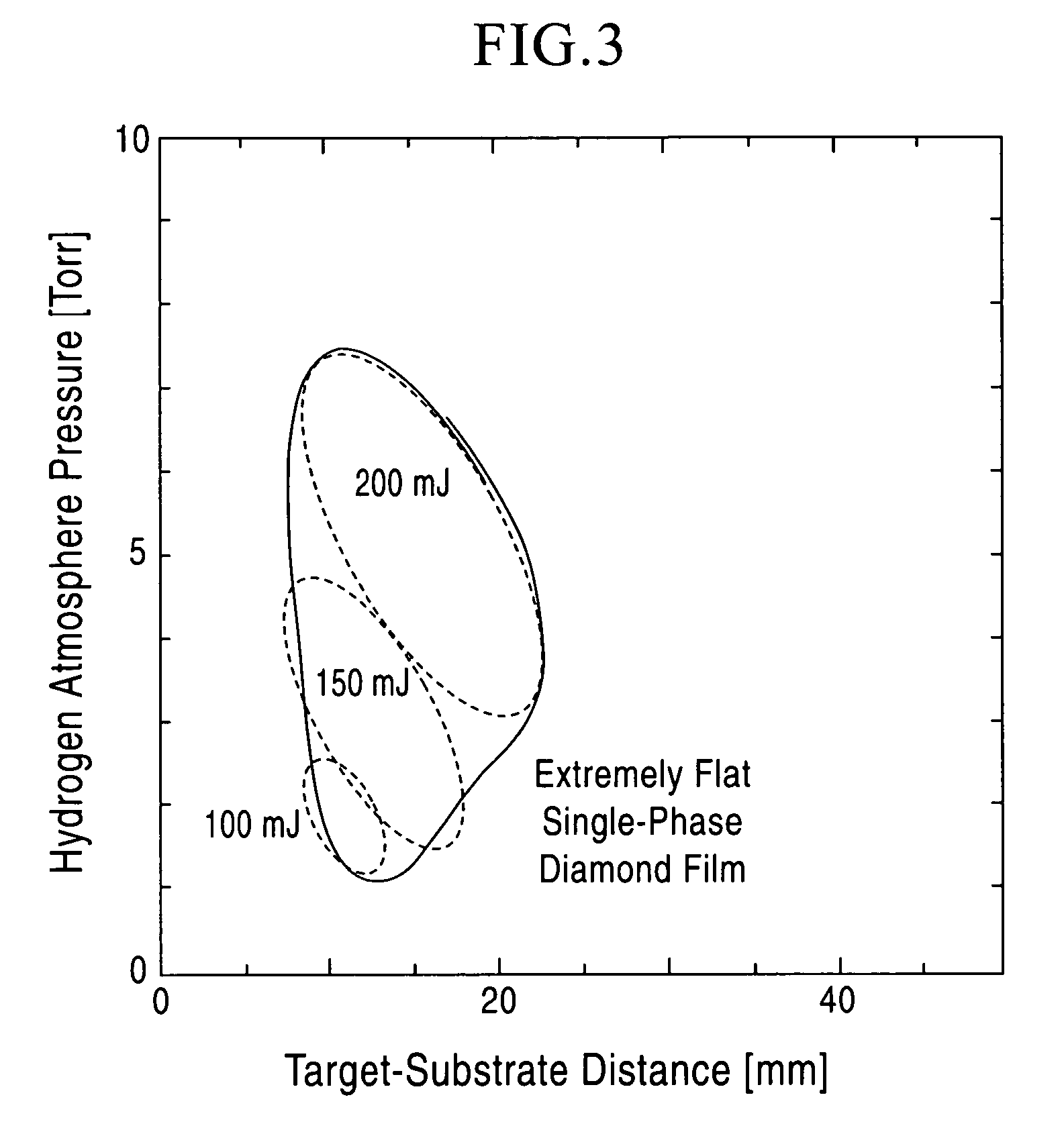

example 1

[0059] The hydrogen pressure was 4 Torr. For the hydrogen pressure, a film that was ultraflat over the surface was observed, as shown in FIG. 6. According to Raman spectrometry, only a shape peak at 1,333 cm−1, which is attributed to diamond, was observed, as shown in FIG. 7. These results indicate the growth of single-phase diamond containing substantially no non-diamond component.

[0060] A comparison of the SEM image in FIG. 6 with the SEM image in FIG. 8, which shows a diamond film produced using oxygen as an atmospheric gas, reveals that the film produced using hydrogen as an atmospheric gas was ultraflat. FIG. 9 shows an AFM image of the diamond film produced in Example 1. FIG. 10 shows a surface irregularity profile obtained by AFM measurement. A stripe pattern derived from the diamond substrate was observed. The average surface roughness was measured to be 2.2 nm; the film can be determined to be ultraflat at the atomic level with a roughness of about 1 nm or less without the...

example 2

[0063] A continuous, ultraflat, single-phase nanocrystalline diamond thin film grew under the same conditions as in Example 1 except that the laser energy was 150 mJ, the target-substrate distance was 15 mm, and the hydrogen pressure was 2 Torr.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com