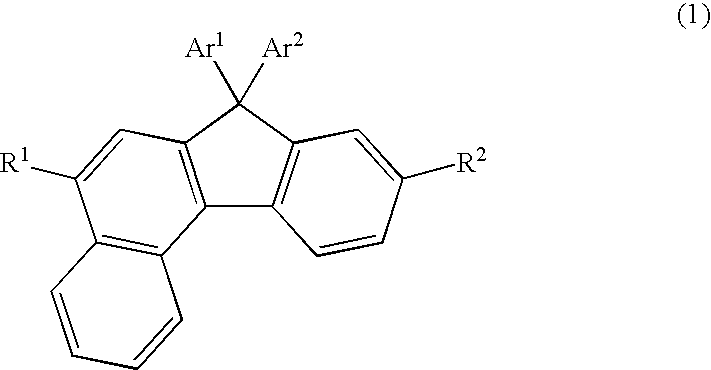

Benzofluorene compound, emission materials and organic electroluminescent device

a technology of organic electroluminescent devices and emission materials, which is applied in the direction of discharge tube luminescnet screens, diaryl/triaryl methane dyes, transportation and packaging, etc., can solve the problems of device life and external quantum efficiency, luminous efficiency, current efficiency, etc., and achieve excellent solubility in solvents, excellent heat resistance, and current efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

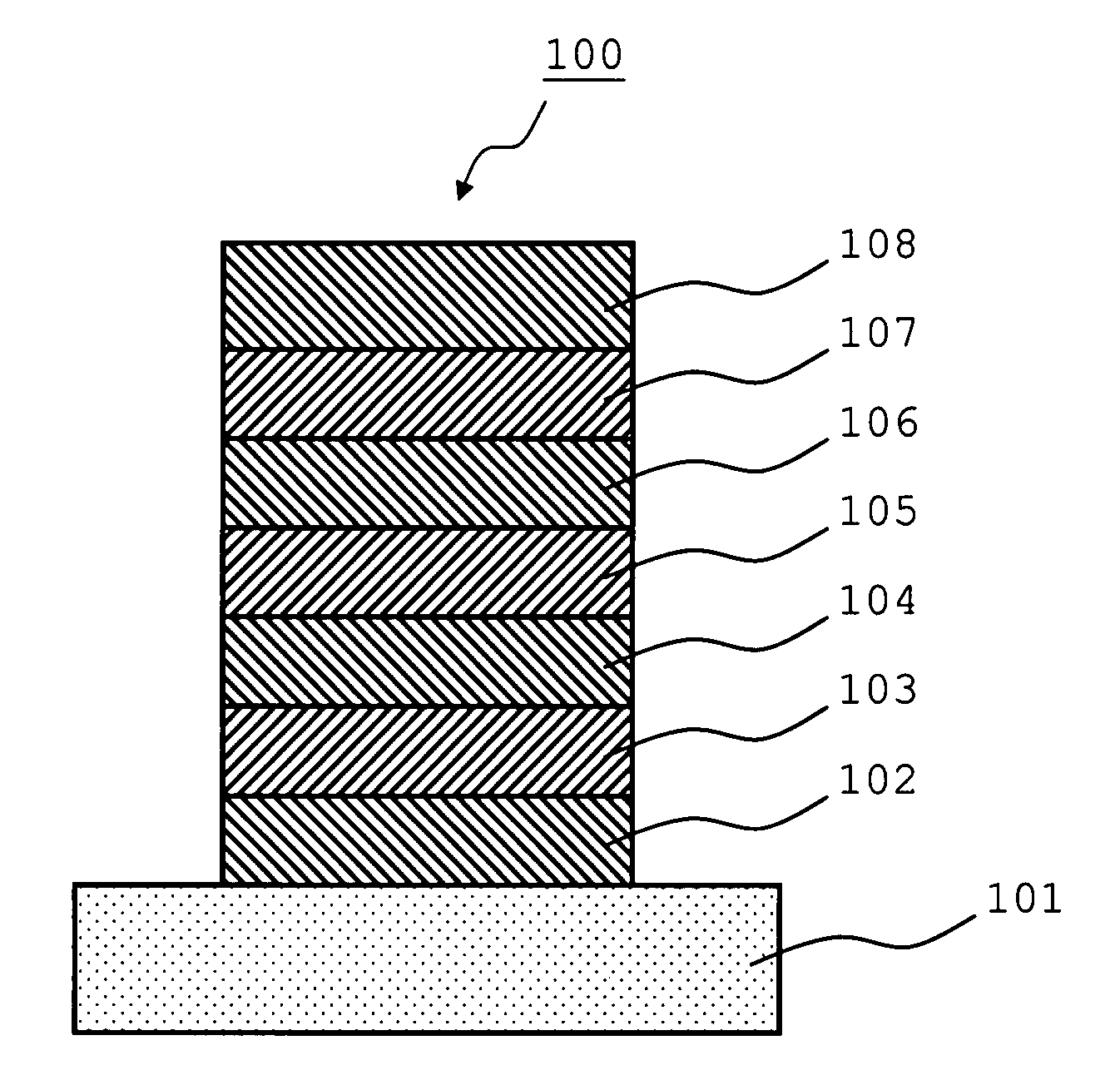

[0176]A glass substrate of 26 mm×28 mm×0.7 mm on which ITO was deposited in a thickness of 150 nm was used as a transparent substrate. This transparent substrate was fixed on a substrate holder of a commercial deposition system, and loaded therein were a molybdenum-made boat for deposition containing CuPc, a molybdenum-made boat for deposition containing NPD, a molybdenum-made boat for deposition containing the compound (1-13), a molybdenum-made boat for deposition containing D1, a molybdenum-made boat for deposition containing ALQ, a molybdenum-made boat for deposition containing lithium fluoride and a tungsten-made boat for deposition containing Aluminum.

[0177]A vacuum chamber was reduced in pressure up to 5×10−4 Pa, and the boat for deposition containing CuPc was heated to deposit it in a layer thickness of 20 nm, whereby a hole injection layer was formed. Then, the boat for deposition containing NPD was heated to deposit it in a layer thickness of 30 nm, whereby a hole transport...

example 2

[0180]An organic EL device was obtained by a method according to Example 1, except that ALQ used for the electron transport layer in Example 1 was changed to ET1. With the ITO electrode set to an anode and the lithium fluoride / aluminum electrode set to a cathode, the characteristics in emission of 100 cd / m2 were measured to find that the voltage was 3.7 V; the current density was 1.6 mA / cm2; the luminous efficiency was 5.4 μm / W; the current efficiency was 6.3 cd / A; the emission wavelength was 455 nm; and the chromaticity was (0.145, 0.168). Further, the external quantum efficiency was 4.9%, and the current density in the external quantum efficiency was 10 mA / cm2. The constant current operation test was carried out at current density for obtaining an initial luminance of 1000 cd / m2 to find that the luminance retention rate was 76.2% after 200 hours passed.

example 3

[0181]A glass substrate of 26 mm×28 mm×0.7 mm on which ITO was deposited in a thickness of 150 nm was used as a transparent substrate. This transparent substrate was fixed on a substrate holder of a commercial deposition system, and loaded therein were a molybdenum-made boat for deposition containing CuPc, a molybdenum-made boat for deposition containing NPD, a molybdenum-made boat for deposition containing the compound (1-4), a molybdenum-made boat for deposition containing D1, a molybdenum-made boat for deposition containing ALQ, a molybdenum-made boat for deposition containing lithium fluoride and a tungsten-made boat for deposition containing Aluminum.

[0182]A vacuum chamber was reduced in pressure up to 5×10−4 Pa, and the boat for deposition containing CuPc was heated to deposit it in a layer thickness of 50 nm, whereby a hole injection layer was formed. Then, the boat for deposition containing NPD was heated to deposit it in a layer thickness of 30 nm, whereby a hole transport ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com