Layered carbon electrodes useful in electric double layer capacitors and capacitive deionization and methods of making the same

a carbon electrode and double layer technology, applied in the direction of electrolytic capacitors, coatings, chemistry apparatuses and processes, etc., can solve the problems of reducing reducing the efficiency of the electrode, so as to improve the mechanical integrity of the layered structure, and improve the effect of electronic resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

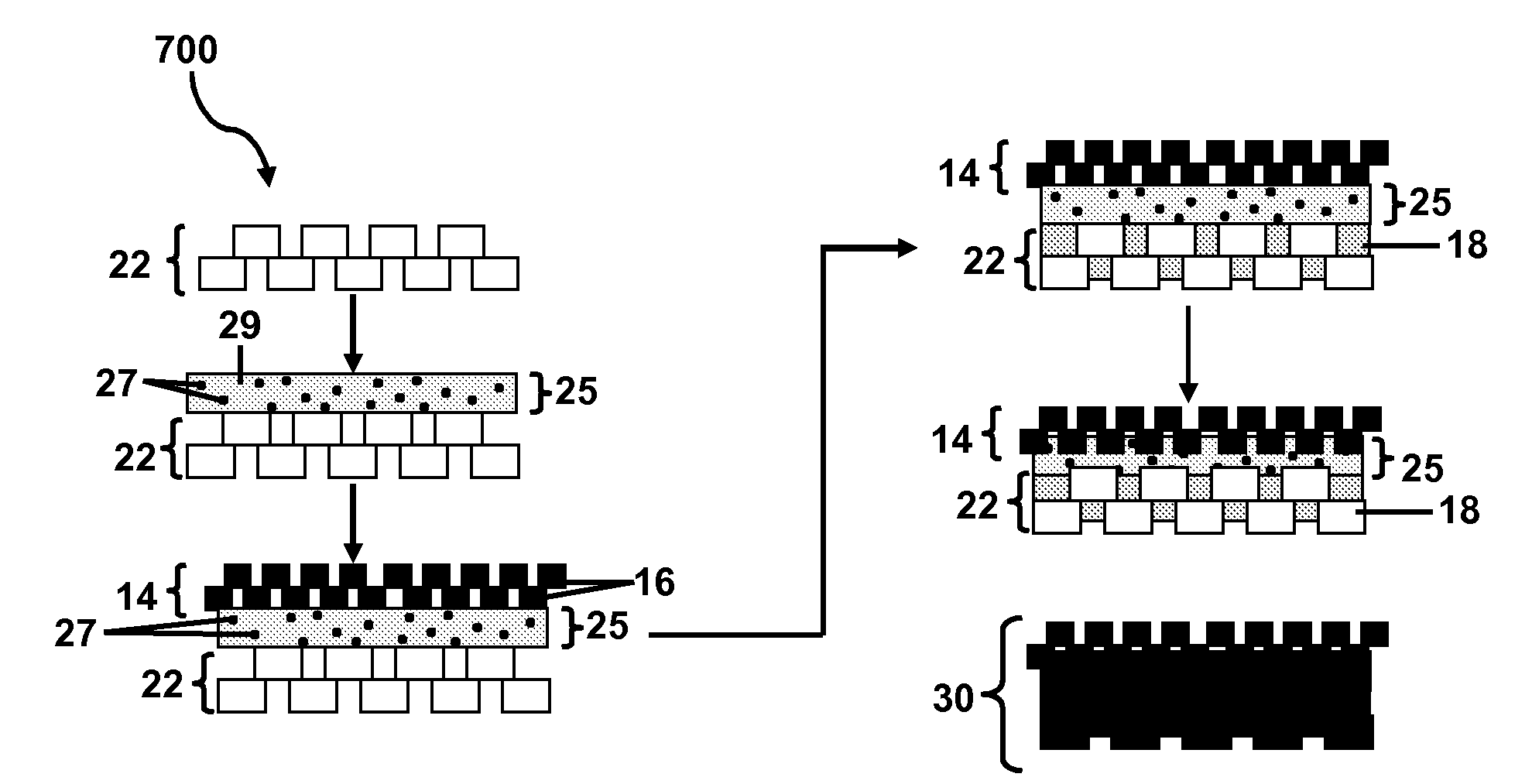

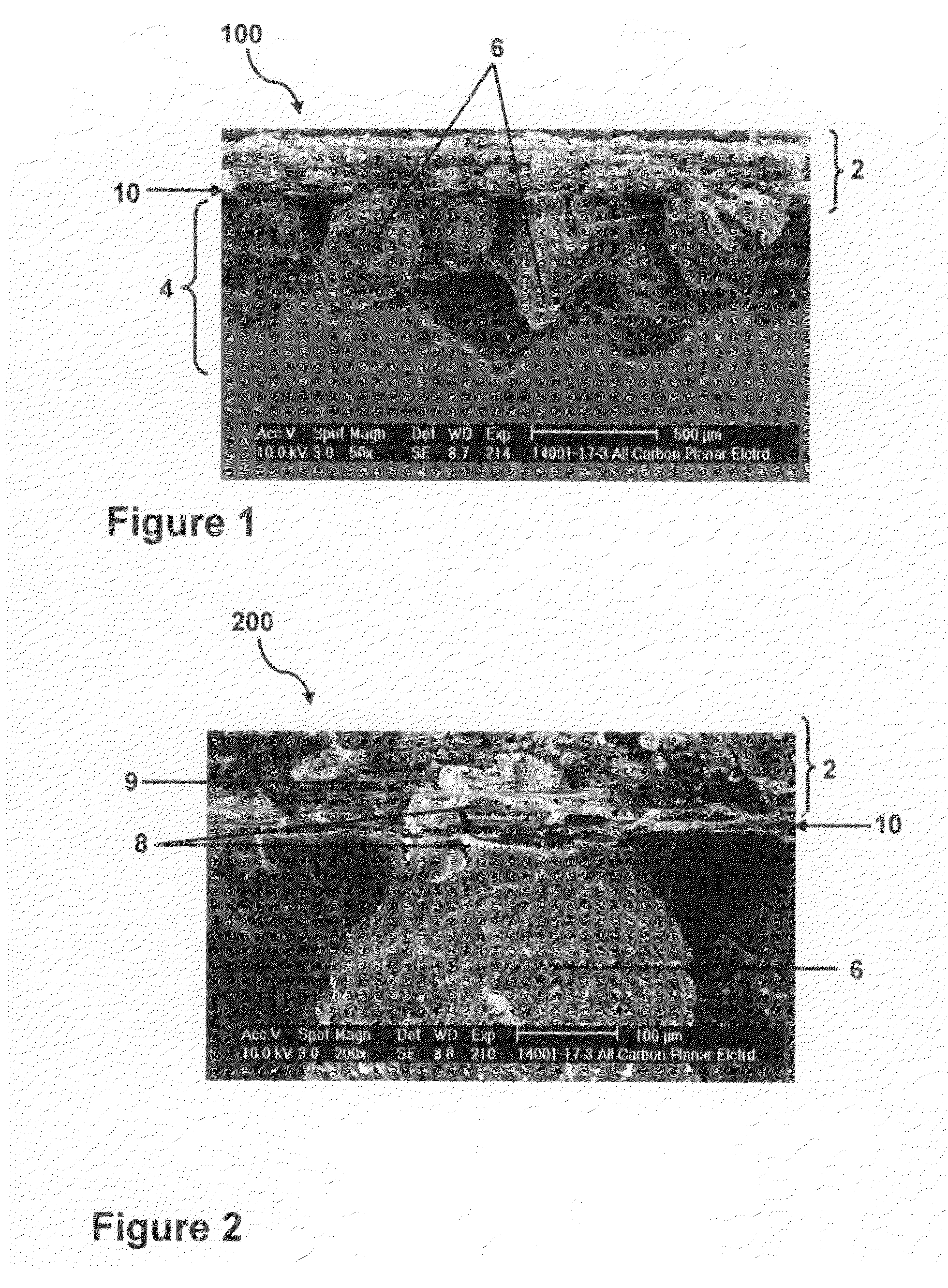

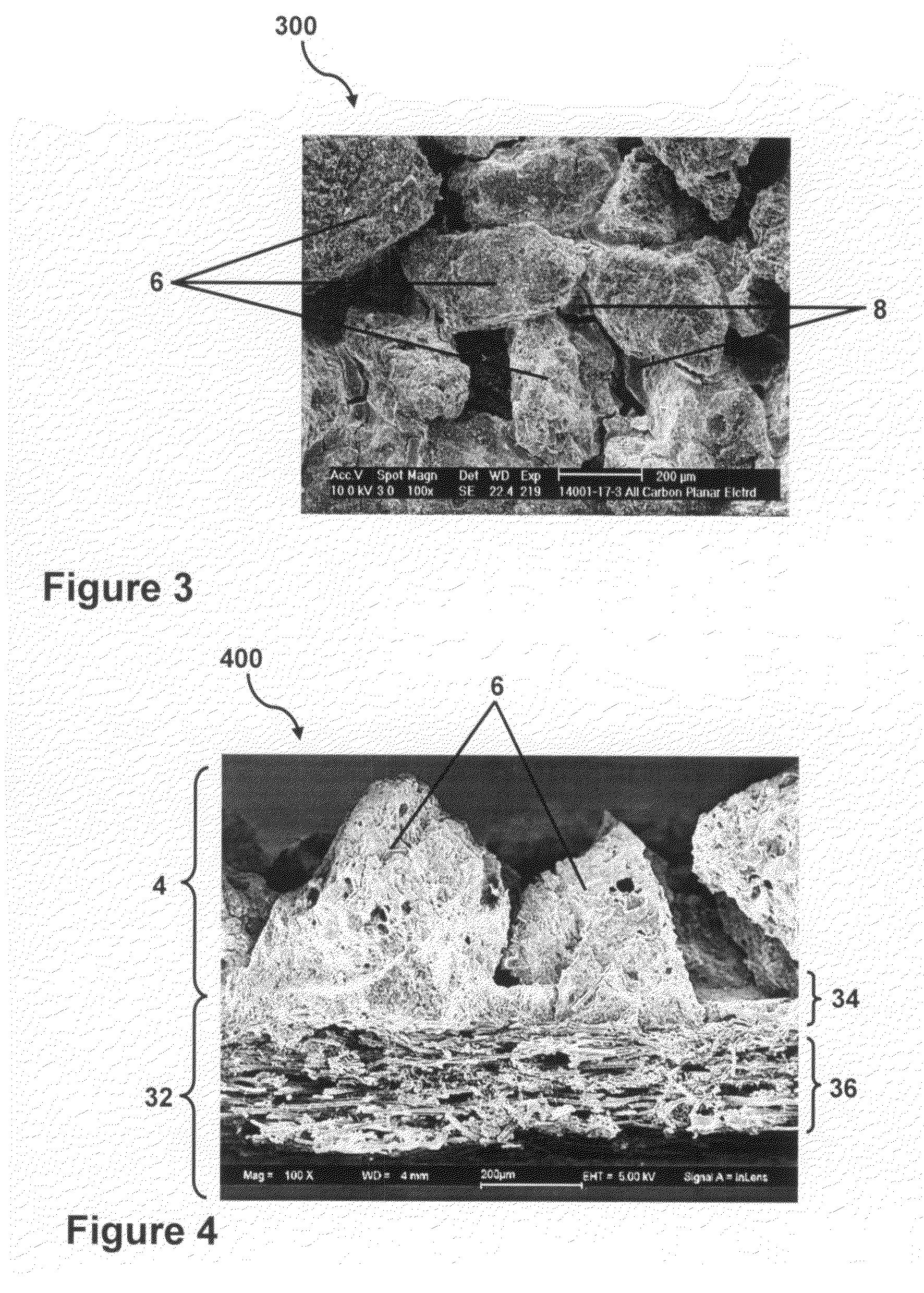

[0041]Reference will now be made in detail to various embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0042]In embodiments, as shown in FIG. 1, FIG. 2 and FIG. 3, a carbon electrode 100, 200, 300 respectively comprises a carbon cover layer 4 comprising carbon particles 6 in contact with an electrically conductive porous carbon support 2. A carbonized material 8 is within the electrically conductive porous carbon support 2 and provides a bond to the carbon particles 6 at the interface 10 with the carbon cover layer 4.

[0043]In another embodiment, as shown in FIG. 5, a layered structure is disclosed. The layered structure 500 comprises an electrically conductive support 52, an adjacent carbon cover layer 54 comprising carbon particles or precursors thereof 56 in contact with the electrically conductive support 52 and a carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com