Aloe Vera Extract, Method of Producing Aloe Vera Extract, and Hyperglycemia Improving Agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0163](Production of Aloe vera Extract)

[0164]For 60 kg of Aloe vera, leaf skins were peeled, and mesophyll (transparent gel) parts were collected. The collected mesophyll parts were freeze-dried, to thereby prepare 300 g of Aloe vera mesophyll powder.

[0165]Extraction was carried out for 20 g of the resultant Aloe vera mesophyll powder by the supercritical fluid extraction method. The supercritical fluid extraction was carried out using CO2 delivery pump (SCF-GET), PU-2080 pump (PU-2080 plus), and Back Pressur Regulator (SCF-BPG), manufactured by JASCO Corporation, and a blunger manufactured by TOYO KOATSU Co., Ltd., and using carbon dioxide as an extraction solvent under conditions of extraction temperature: 50° C., extraction pressure: 15 MPa, and extraction time: 60 minutes without using an entrainer. As a result, 33 mg of Aloe vera extract was produced.

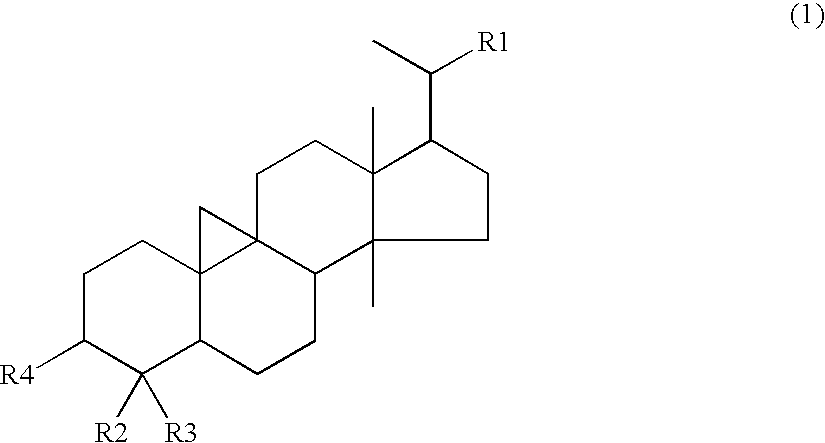

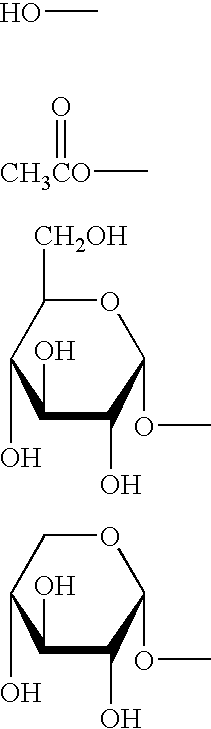

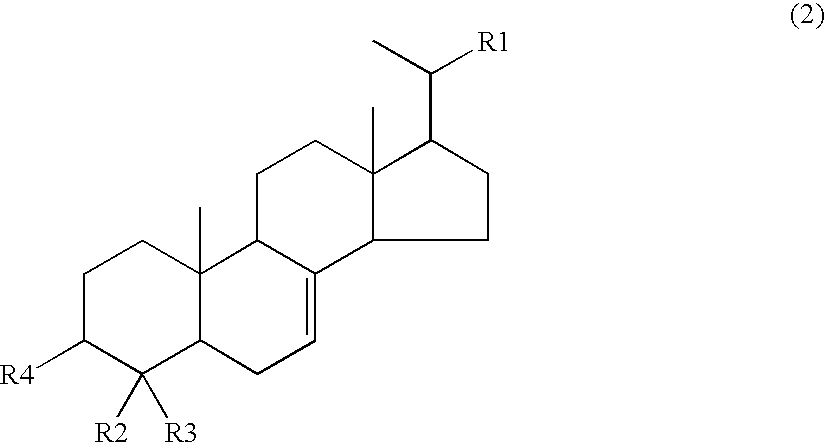

[0166]For the resultant Aloe vera extracts, the compositions were analyzed by LC-MS. The results revealed that: the extracts cont...

example 2

[0168]A tablet drug having the following composition and having a hyperglycemia improving effect was produced by the following method.

[0169]Aloe vera extract produced in Example 1 (dry product) 40 (%) Lactose (manufactured by Morinaga Milk Industry Co., Ltd.) 18.5

[0170]Corn starch (manufactured by Nisshin Seifun Group Inc.) 30.7

[0171]Magnesium stearate (manufactured by Taihei Chemical Industrial Co., Ltd.) 1.4

[0172]Carboxymethylcellulose calcium (Gotoku Chemical Company Co., Ltd.) 9.4

[0173]A mixture of an Aloe vera extract (dry product), lactate, corn starch, and carboxymethylcellulose calcium was uniformly kneaded while appropriately adding sterile purified water, and the mixture was dried at 50° C. for 3 hours. Magnesium stearate was added to the resultant dry product, and the mixture was mixed, followed by making tablet in accordance with a conventional method, to thereby yield a tablet containing a mixture of a cyclolanostane compound and a lophenol compound in an amount of abou...

example 3

[0174]10.8 kg of an enzymatically degraded product of whey protein (manufactured by Morinaga Milk Industry Co., Ltd.), 36 kg of dextrin (manufactured by Showa Sangyo Co., Ltd.), and small amounts of a water-soluble vitamin and a mineral were dissolved in 200 kg of water to prepare an aqueous phase in a tank. On the other hand, 3 kg of soybean cooking oil (manufactured by Taiyo-yushi Co. Ltd.), 8.5 kg of palm oil (manufactured by Taiyo-yushi Co. Ltd.), 2.5 kg of safflower oil (manufactured by Taiyo-yushi Co. Ltd.), 0.2 kg of lecithin (manufactured by Ajinomoto Co., Inc.), 0.2 kg of fatty acid monoglyceride (manufactured by Kao Corporation), and a small amount of a fat-soluble vitamin were mixed and dissolved to prepare an oil phase. The oil phase was added to the aqueous phase in the tank and mixed by stirring, and the mixture was heated to 70° C., followed by homogenization using a homogenizer at a pressure of 14.7 MPa. Subsequently, the homogenate was sterilized at 90° C. for 10 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com