Methods and Compositions for Preparing Tensile Strained Ge on Ge1-ySNy Buffered Semiconductor Substrates

a technology of strained ge and buffered semiconductors, applied in the direction of basic electric elements, electrical equipment, semiconductor devices, etc., can solve the problems of non-uniform and potentially defective interfaces, stress as a perturbation, and lack of precise strain control, so as to achieve high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

General Deposition Procedures

Example 1a

GeSn Buffer Deposition

[0047]Ge1-ySny buffer layers (y=0.02-0.04) were deposited on hydrogen-passivated Si(100) wafers at 330-350° C., as described previously (see, Bauer et al., Appl. Phys. Lett. 81, 2992 (2002), which is hereby incorporated by reference in its entirety). The as-grown Ge1-ySny films were ˜93-95% relaxed (even for thicknesses less than 100 nm) and achieve strain relief from the substrate by generating Lomer dislocations that run parallel to the film / substrate interface. The residual strain was relieved by in situ thermal cycling for 30 minutes at 500-600° C. or by rapid thermal annealing up to 850° C. for several seconds, depending on composition. These steps also reduces the density of threading defects penetrating to the surface to levels below 106 / cm2. Atomic force microscopy (AFM) shows planar surfaces for both the as-grown and annealed Ge1-ySny buffers that provide an ideal platform for subsequent growth. The typical RMS ro...

example 1b

Tensile Strained Ge Deposition

[0048]Growth of Ge epilayers was conducted ex situ on the relaxed Ge1-ySny buffers (y=0.02-0.04) via gas-source molecular beam epitaxy (MBE) at 340-380° C. and 5×10−5 Torr using 1:15 admixtures of (GeH3)2CH2 and Ge2H6. This combination of compounds was designed to provide built-in pseudo surfactant growth behavior enabling the fabrication of dislocation free, and atomically flat Ge films with no measurable carbon incorporation. SIMS measurements indicate C content at the detection limit (17 cm−3) (see, Wistey et al., Appl. Phys. Lett., 90, 082108 (2007)).

[0049]The reaction mixture of (GeH3)2CH2 in Ge2H6 was prepared prior to each deposition by combining the pure compounds in a 100 mL vacuum flask. The total pressure was 115 Torr, which is well below the vapor pressure of (GeH3)2CH2 (248 Torr at 25° C.). The flask was connected to a gas injection manifold which was pumped to ˜10−8 Torr on the gas source MBE chamber.

[0050]Prior to Ge growth, the Ge1-ySny / ...

example 2

Structural and Optical Characterization

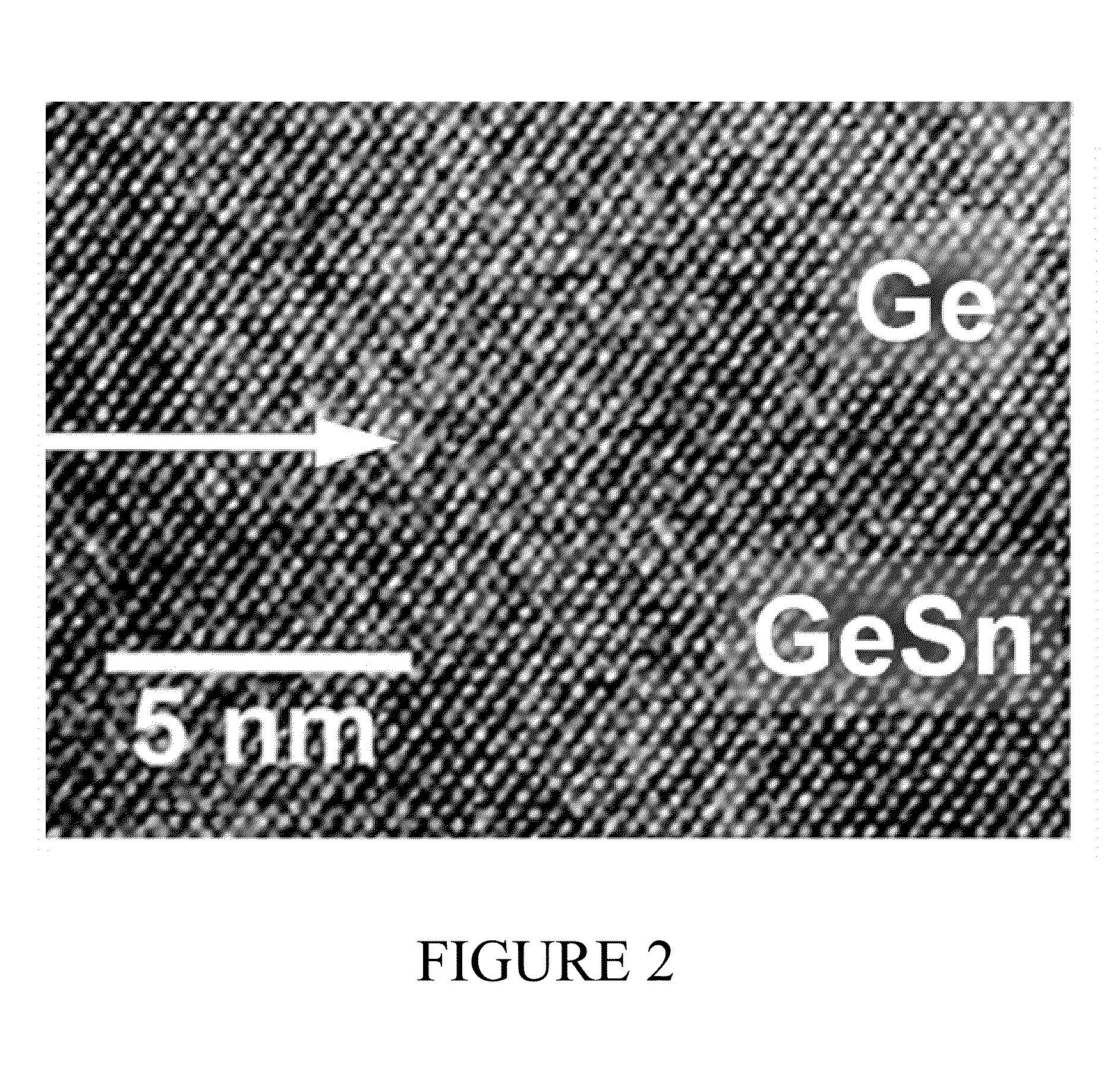

[0053]The samples prepared according to Example 1 were extensively characterized for morphology, microstructure, purity and crystallographic properties by atomic force microscopy (AFM), Rutherford backscattering (RBS), secondary ion mass spectrometry (SIMS), cross sectional transmission electron microscopy (XTEM) and high resolution x-ray diffraction (XRD). The threading defects densities were estimated using an etch pit technique (EPD).

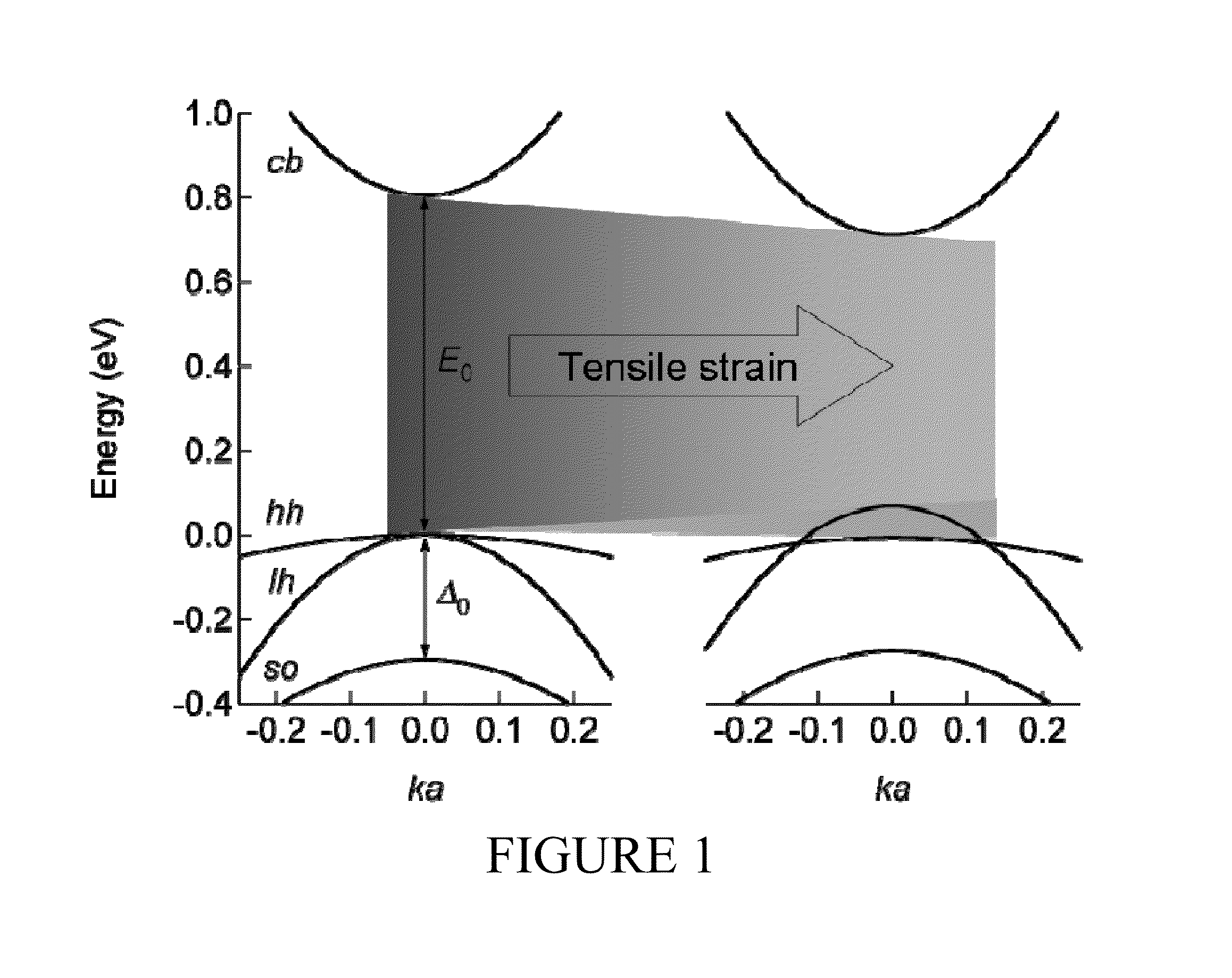

[0054]As detailed below, the precise strain state of the Ge epilayers case can be systematically manipulated by varying the thickness and composition of the underlying template, for example, via tuning of the Sn content in the Ge1-ySny buffer. Growth of Ge layers on buffers with smaller / larger lattice constants, such as Ge1-ySny with y=0.015-0.035,) systematically produced larger strains in the Ge overlayers with increasing y, within the 1.5-3.5% range.

[0055]We have used the Ge1-ySny buffer layers (y=0.015-0.035...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strain | aaaaa | aaaaa |

| tensile strain | aaaaa | aaaaa |

| band gap E0 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com