Modified silk films containing glycerol

a technology of glycerol and silk fibroin, which is applied in the field of modified silk fibroin films containing glycerol, can solve the problems of low ductility, stiffness and brittleness of silk fibroin films, and high tensile strength of silk fibroin films, and achieve enhanced aqueous solubility and biocompatibility, enhanced biocompatibility and the potential to load bioactive compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Silk Fibroin Purification

[0065]Silk fibroin aqueous stock solutions were prepared as previously described. Sofia et al., 54 J. Biomed. Mater. Res. 139-48 (2001). Briefly, cocoons of Bombyx mori were boiled for 20 min in an aqueous solution of 0.02 M sodium carbonate, and then rinsed thoroughly with pure water. After drying, the extracted silk fibroin was dissolved in 9.3 M LiBr solution at 60° C. for 4 hr, yielding a 20% (w / v) solution. This solution was dialyzed against distilled water using SLIDE-A-LYZER® Dialysis Cassettes, 3,500 MWCO (Pierce, Rockford, Ill.) for 3 days to remove the salt. The solution was optically clear after dialysis and was centrifuged to remove the small amounts of silk aggregates that formed during the process, usually from environment contaminants that are present on the cocoons. The final concentration of silk fibroin aqueous solution was approximately 6% (w / v). This concentration was determined by weighing the residual solid of a known volume of solution...

example 2

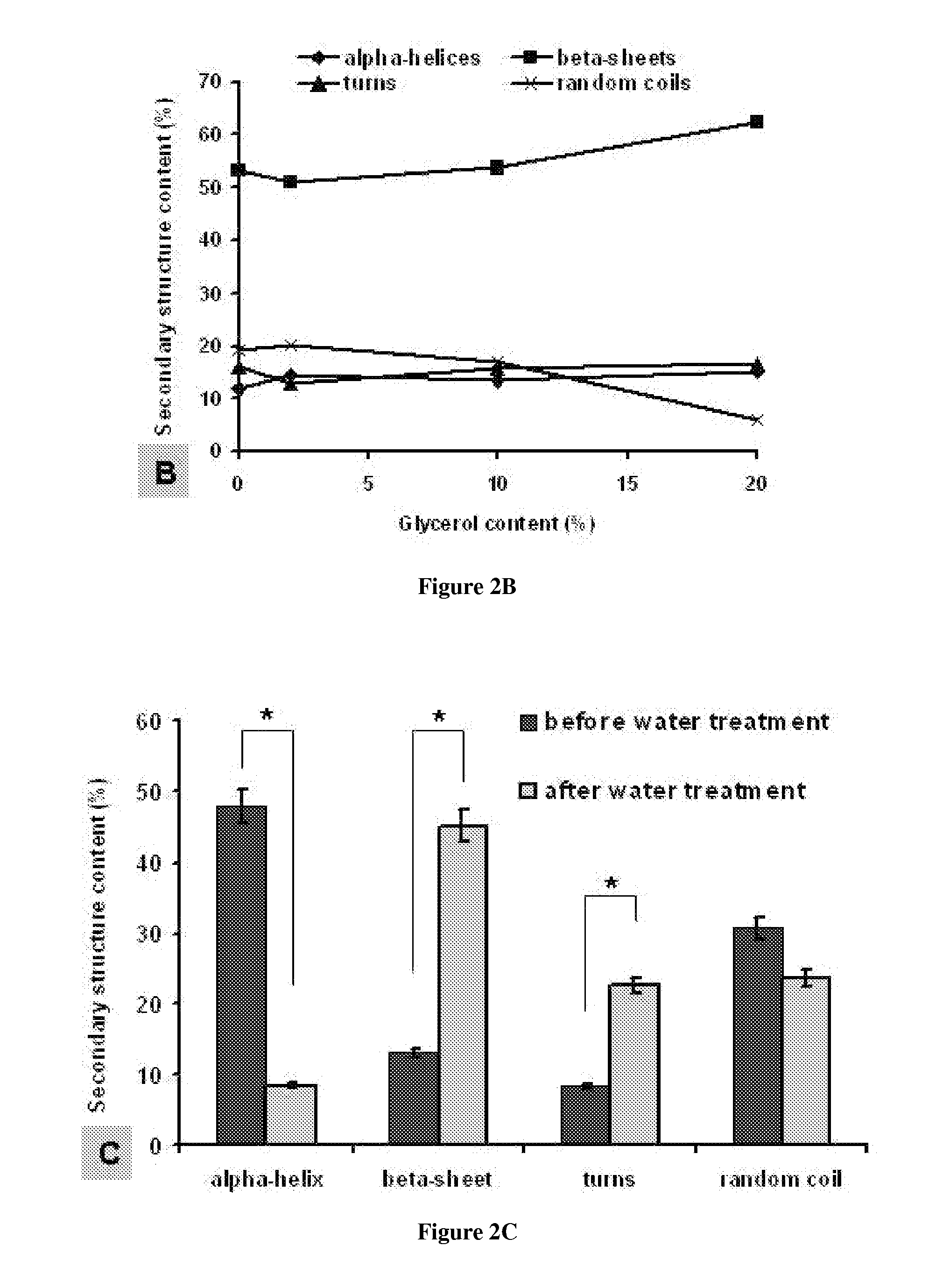

Preparation of Silk / Glycerol Blend Films

[0067]The purified silk fibroin solution was mixed with glycerol at weight ratios of 0%, 5%, 10%, 20%, 30%, 40%, 50% (w / w). The mixed solutions were poured into Petri dishes and dried at room temperature in a laminar flow hood overnight. Unless otherwise stated, the ‘dry blend films’ refers to the films prepared by this direct casting and overnight drying, and the ‘wet blend films’ refers to the same cast and dried films from which the glycerol is subsequently extracted in ultrapure water at 37° C. for 1 hr, after which the films are dried again in the air. For additional variables in the treatment groups, methanol treatments were used, and in these cases the films (with and without glycerol) were immersed in 90% (v / v) methanol for 1 hr and then air-dried.

example 3

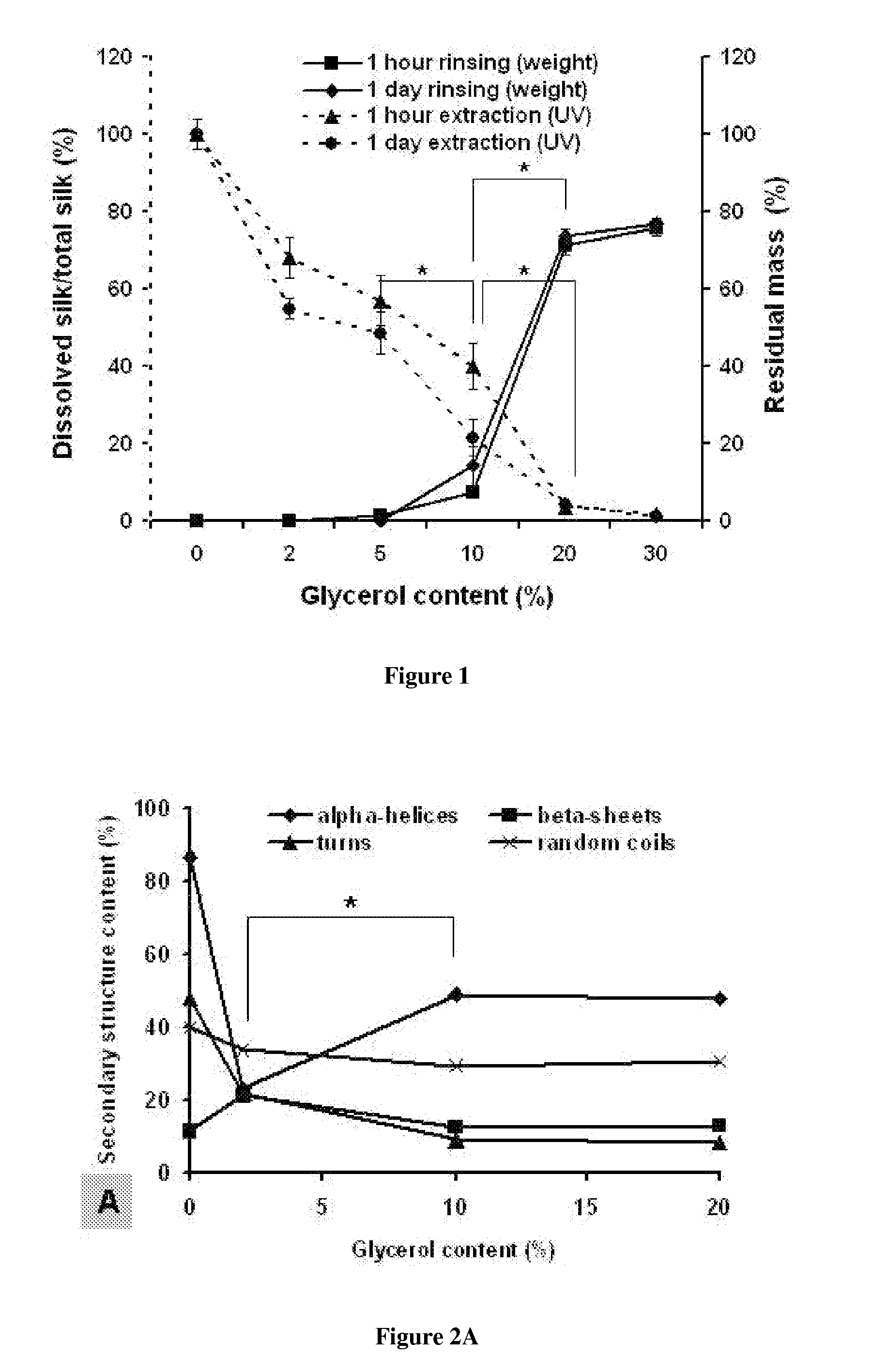

Dissolution of silk / glycerol films

[0068]Blend films were cut into approximately 5 mm×5 mm squares, and one square film was weighed and immersed in ultrapure water in a 2 ml tube to a concentration of 1% (weight of film / volume of water), and kept at 37° C. for 1 hr or 1 day. After the incubation, the silk films were removed from the solution, air-dried overnight, weighed, and compared with the mass of original film to obtain residual mass (%). The remaining solution was subjected to UV absorbance measurement at 280 nm. The absorbance values were converted to the amount of silk solubilized in water using purified silk fibroin solution at various concentrations as standards. The amount of dissolved silk was then compared with the total silk mass in the film to obtain the percentage of the film dissolved silk in water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| w/w | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com