Lubricating Oil Composition

a technology of lubricating oil and composition, applied in the direction of liquid carbonaceous fuels, fuel additives, additives, etc., can solve the problems of oxidation catalysts being poisoned and less effective, and achieve the effect of reducing the tendency of base stocks to deteriora

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

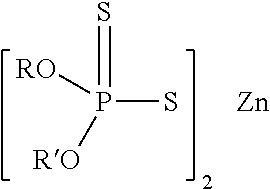

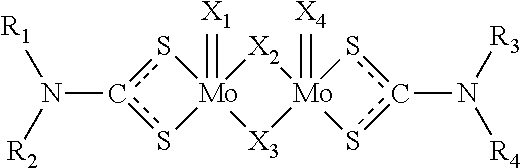

[0077]Lubricating oil composition Oil B, was prepared by mixing an additive package comprising 4.8 mass % of a polyisobutenyl succinimide dispersant made from a polyisobutenyl with a number average molecular weight (Mn) of 2225, 1.08 mass % of polyisobutenyl succinimide dispersants made from a polyisobutenyl with a number average molecular weight (Mn) of 950, 0.84 mass % of a 321 TBN overbased calcium salicylate detergent and 0.34 mass % of a 565 TBN overbased calcium salicylate detergent, 0.43 mass % a 709 TBN of overbased magnesium sulfonate detergent, 0.84 mass % of HiTec 5777 dispersant-viscosity modifier, and zinc dialkyl dithiophosphate, molybdenum dithiocarbamate and antioxidant, into a base stock comprising a mixture of Group I and Group III base oils. Oil B comprised 1.0 wt % sulphated ash, 0.08 wt % phosphorous, 0.21 wt % sulfur, 130 ppm of atomic boron 50 ppm molybdenum, 0.165 mass % calcium and 0.069 mass % magnesium. The salicylate soap content of Oil B was 9.8 mmol and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com