Crystalline microspheres and the process for manufacturing the same

a technology of crystalline microspheres and microspheres, which is applied in the direction of cellulosic plastic layered products, natural mineral layered products, transportation and packaging, etc., can solve the problems of incompatibility with active substances and loss of active substances, lack of release of active substances or lower extraction yields, etc., and achieves low hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

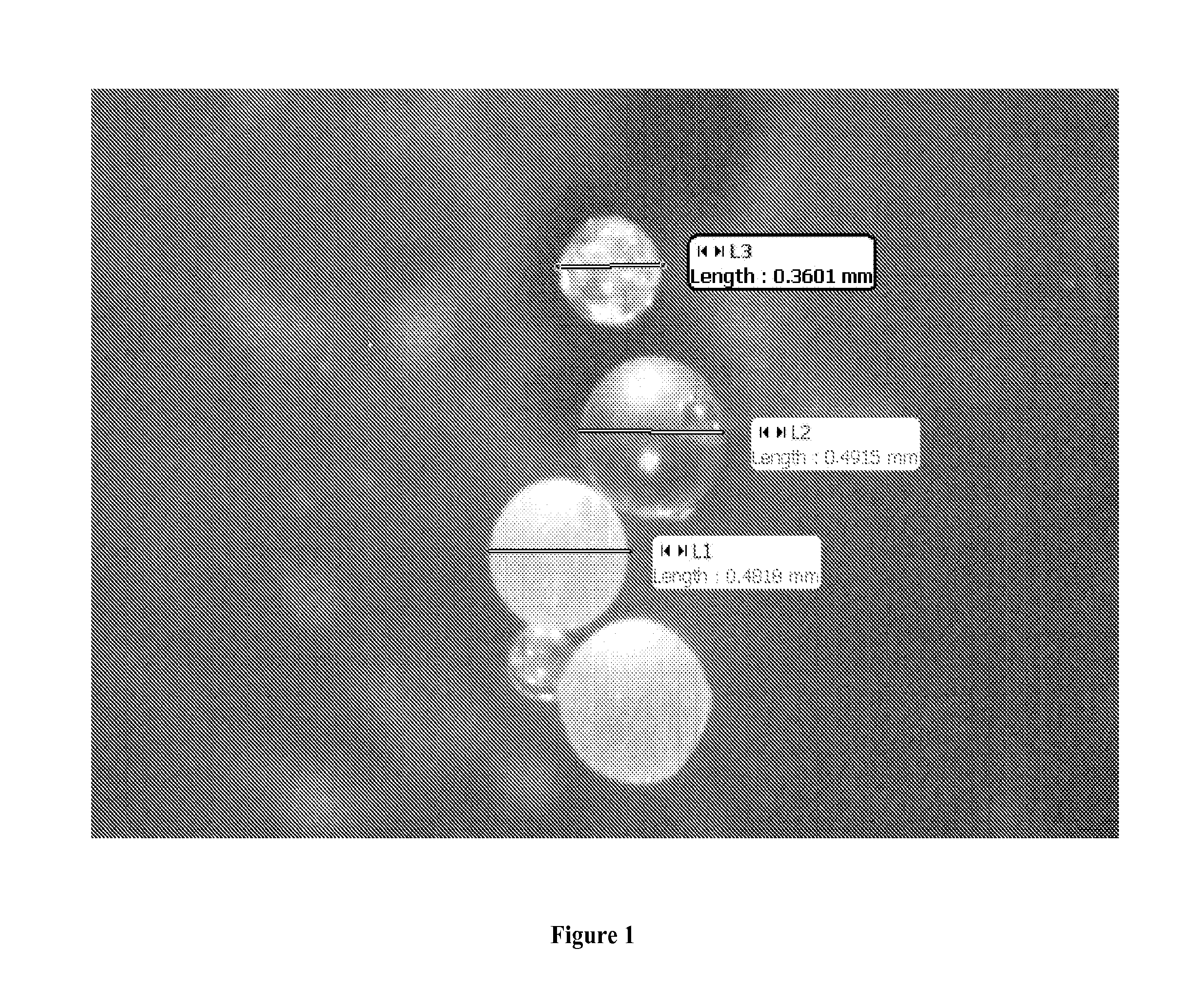

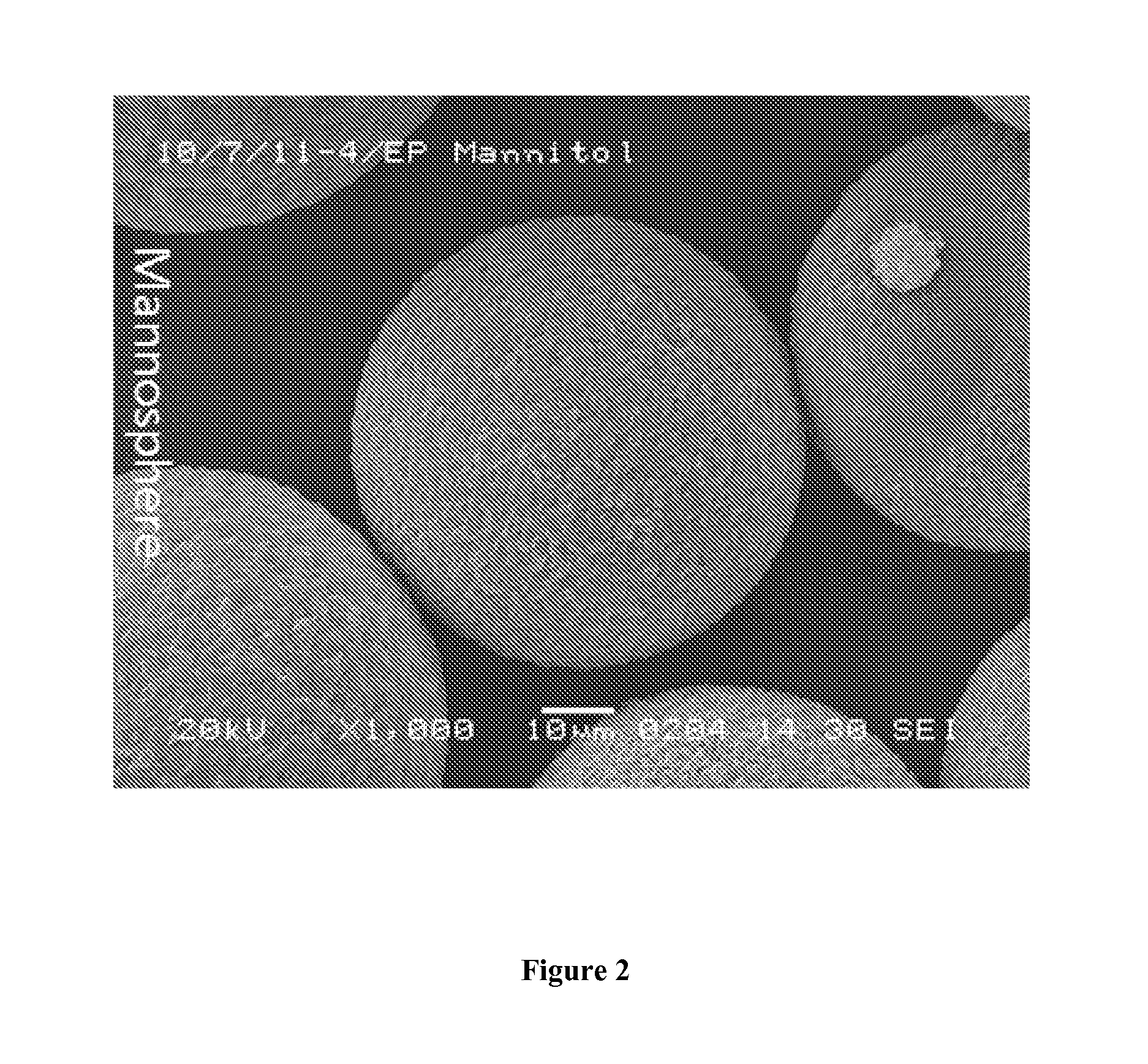

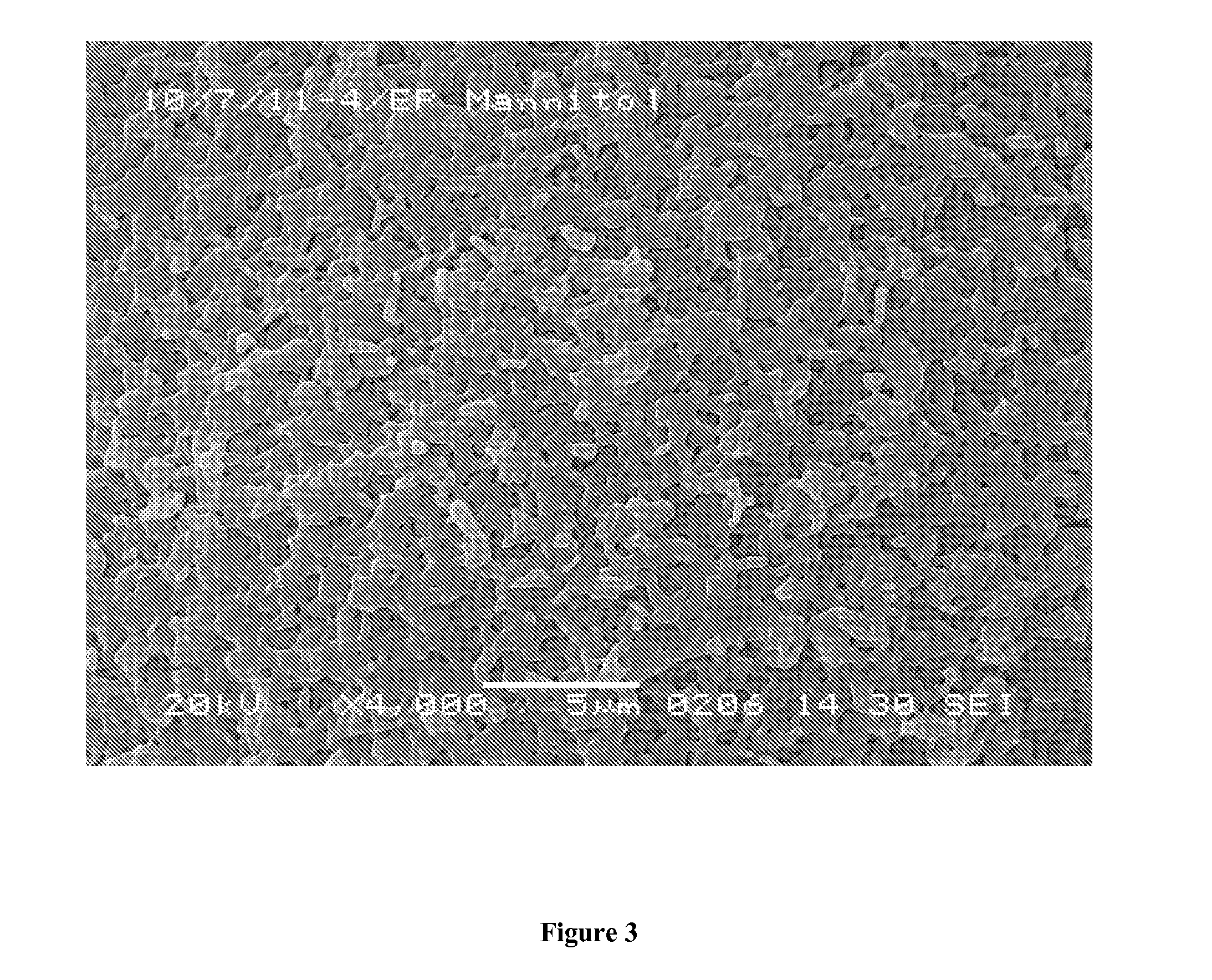

[0102]Mannitol (EP) (Shandong Tianli Pharmaceutical Ltd., Guangzhou, China) and mannitol / sorbitol (2.3%) (sorbitol, Roquette, Keokuk, Iowa) microspheres were produced by prilling (spray chilling) of a melt of the polyols in a stainless steel 2 quart sauce pan. The melted polyol was poured into a heated pressure vessel that was heated by electrical heat bands. The heated pressure vessel was pressurized to 50 psig and the plug valve at the bottom of the vessel was opened to send the mannitol thru the spray line to the nozzle. The spray line was heated by electrical heat tape. The nozzle was heated with a propane torch prior to opening the valve. The prills from the nozzle (Spraying Systems 6501) were collected on plastic and bagged for evaluation. Microspheres particle size distribution was determined by Malvern Mastersizer Laser analysis (Malvern, Pa.). Table 1 shows the particle size distribution of the microspheres. Microsphere diameters were in the 250 μm mean range with a broad d...

example 2

[0103]Mannitol EP (Shandong Tianli Pharmaceutical Ltd., Guangzhou, China), mannitol / sorbitol (2.3%) (sorbitol, Roquette, Keokuk, Iowa) and mannitol / polysorbate 80 (Unichema, New Castle, Del.) microspheres were made by melting polyol and dropping melt to spin disc for formation of microspheres. Mannitol is melted in pan or oven at 10° C. above its melting point for mannitol a temperature higher than 176° C. Once melted, the liquid mannitol is spun into a stream which, by centrifugal force, is spread into a thin film and exits the disk as a ligament that breaks into droplets or exits as droplets. Surface spinner style disk is preferred with a diameter of 4 inches or more and speed capabilities of from 500 RPM to 11,000 RPM. Wheel RPM controls film thickness and thus droplet / bead size. Microspheres are allowed to fall at least 8 feet in room temperature or chilled air to congeal. Once congealed a coarse screen can be used to complete cooling and maintain separation. Any twinning or chi...

example 3

[0137]Erythritol EP (Baolingbao Biology Co., LTD., China) was added to a Tornado Spin Disc (Gold Metal Cincinnati Ohio). The units spin head was heated to ˜160° C. while spinning at 3400 RPM and made microspheres with a PSD of d(0.1)=131 μm, a d(0.5)=262 μm and a d(0.9)=371 μm. The size distribution ratio is 2.8 to 1 for this run. The DSC of these beads shows a single and sharp melt peak at 121.6° C. with a heat of fusion of 273.1 J / g. A pure crystalline erythritol melt range of 199° C. to 121° C. is expected and thus crystal structure of formed microsphere is a standard and highest energy erythritol polymorph.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| mean particle size | aaaaa | aaaaa |

| mean particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com