LPG Fuel System

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

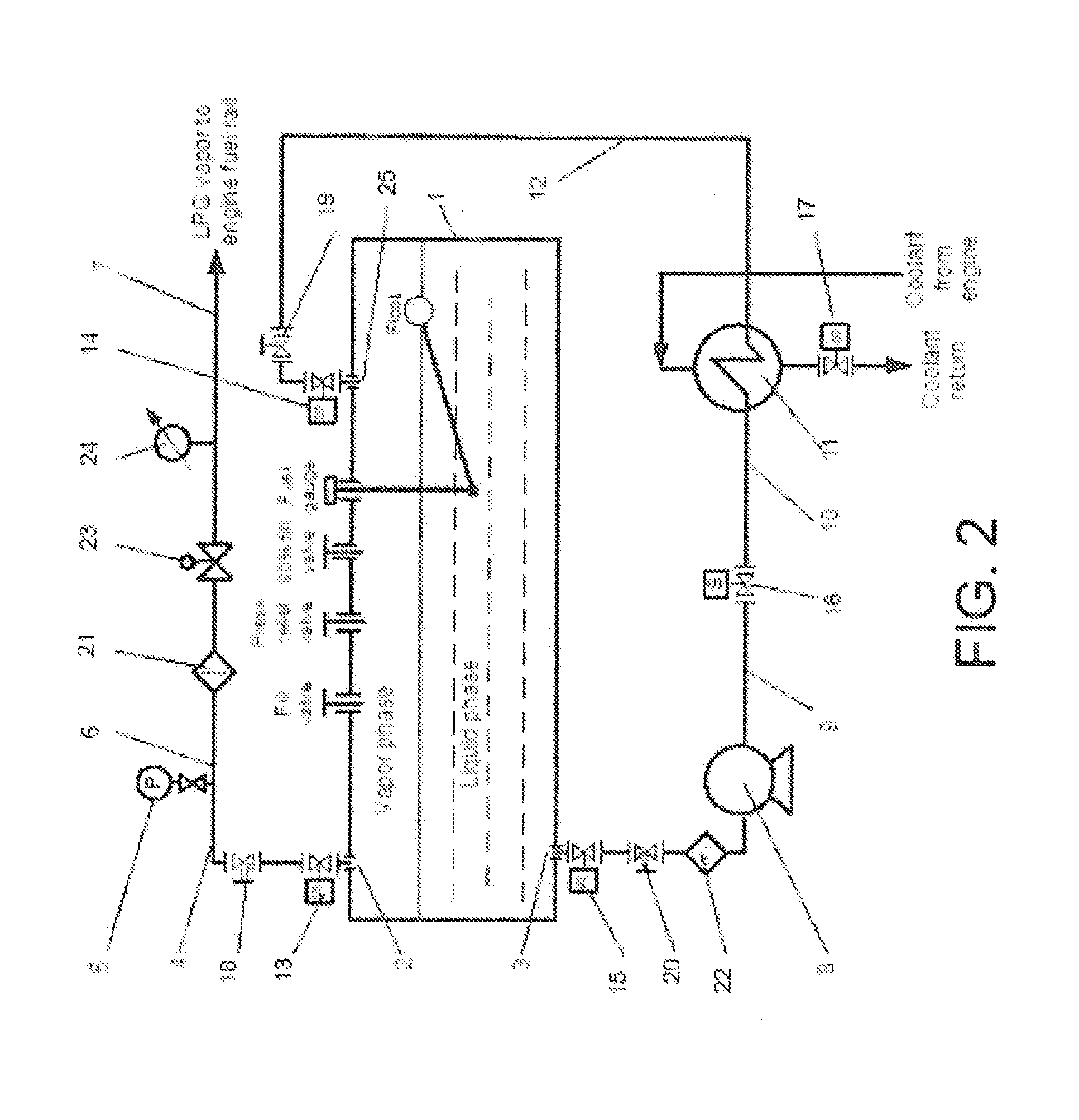

[0031]Generally disclosed is a LPG fuel system. In operation, the invention is accomplished by mixing vaporized LPG with air when the vapor and the air have either balanced heat loads or substantially equalized random kinetic energies. In one embodiment, the balanced heat loads or equalized random kinetic energies between the air and vaporized LPG can be produced by (1) pumping LPG fuel from a fuel tank through a heat exchanger, wherein heat from engine coolant is used to vaporize the LPG fuel; (2) returning the vaporized LPG to the fuel tank so that LPG fuel and vaporized LPG fuel occupy the fuel tank; and (3) mixing vaporized LPG fuel with air from the atmosphere.

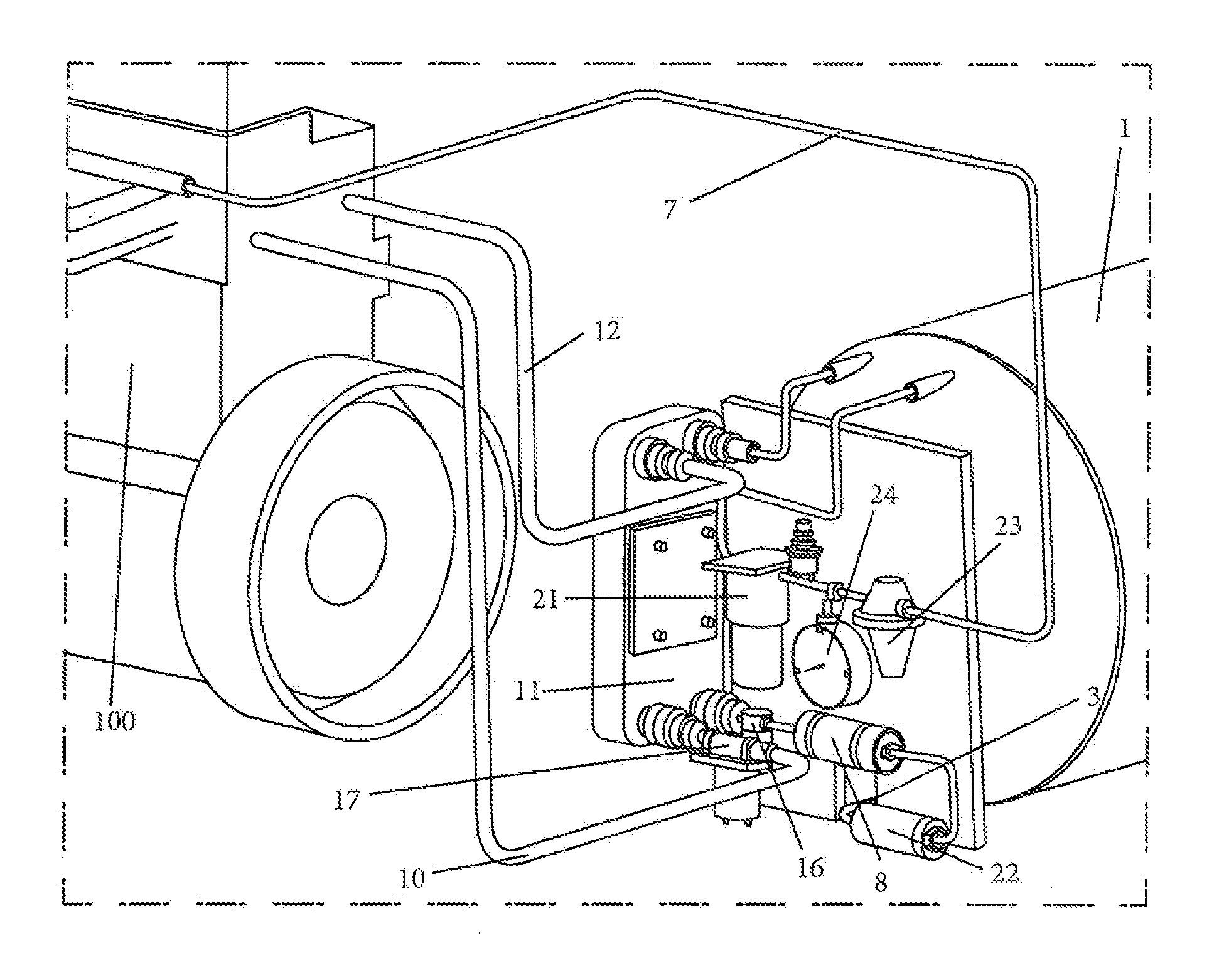

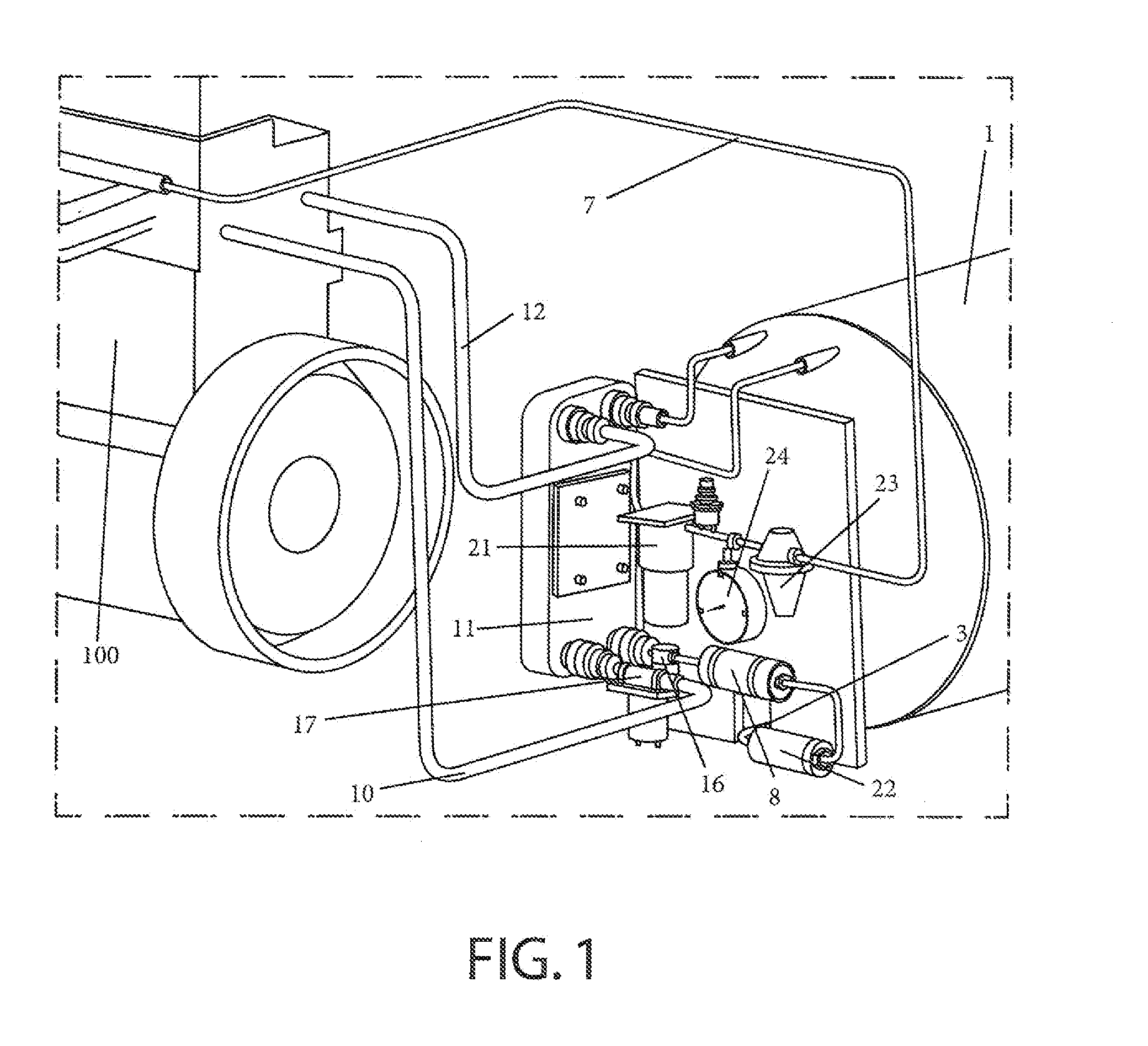

[0032]FIG. 1 is an environmental view of one embodiment of the LPG fuel system for internal combustion engines. In use, LPG fuel may be drawn from the fuel tank 1 through a pipe 3 and a first filter 22 via an electric fuel pump 8. The fuel passes through a fuel solenoid valve 16 into a heat exchanger 11 and then is return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com