An apparatus and method for growing a bulk single crystal nitride material

a single crystal, nitride technology, applied in the direction of crystal growth process, polycrystalline material growth, pressurized chemical process, etc., can solve the problems of high dislocation density of the epitaxial layer, difficult to obtain free-standing gan substrate, czochralski method, etc., to suppress the formation of nitride polycrystal, suppress spontaneous nucleation, and suppress the effect of nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

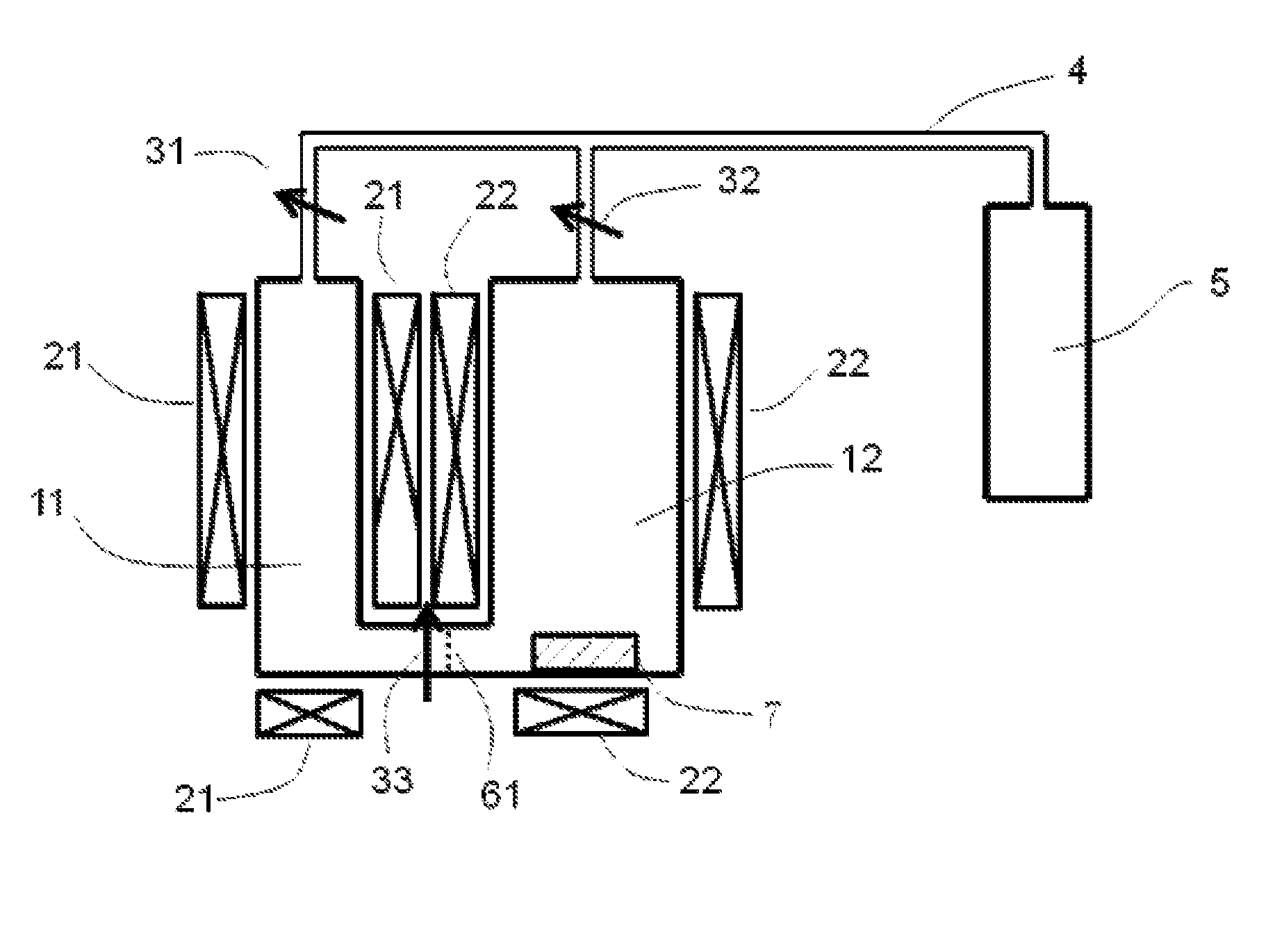

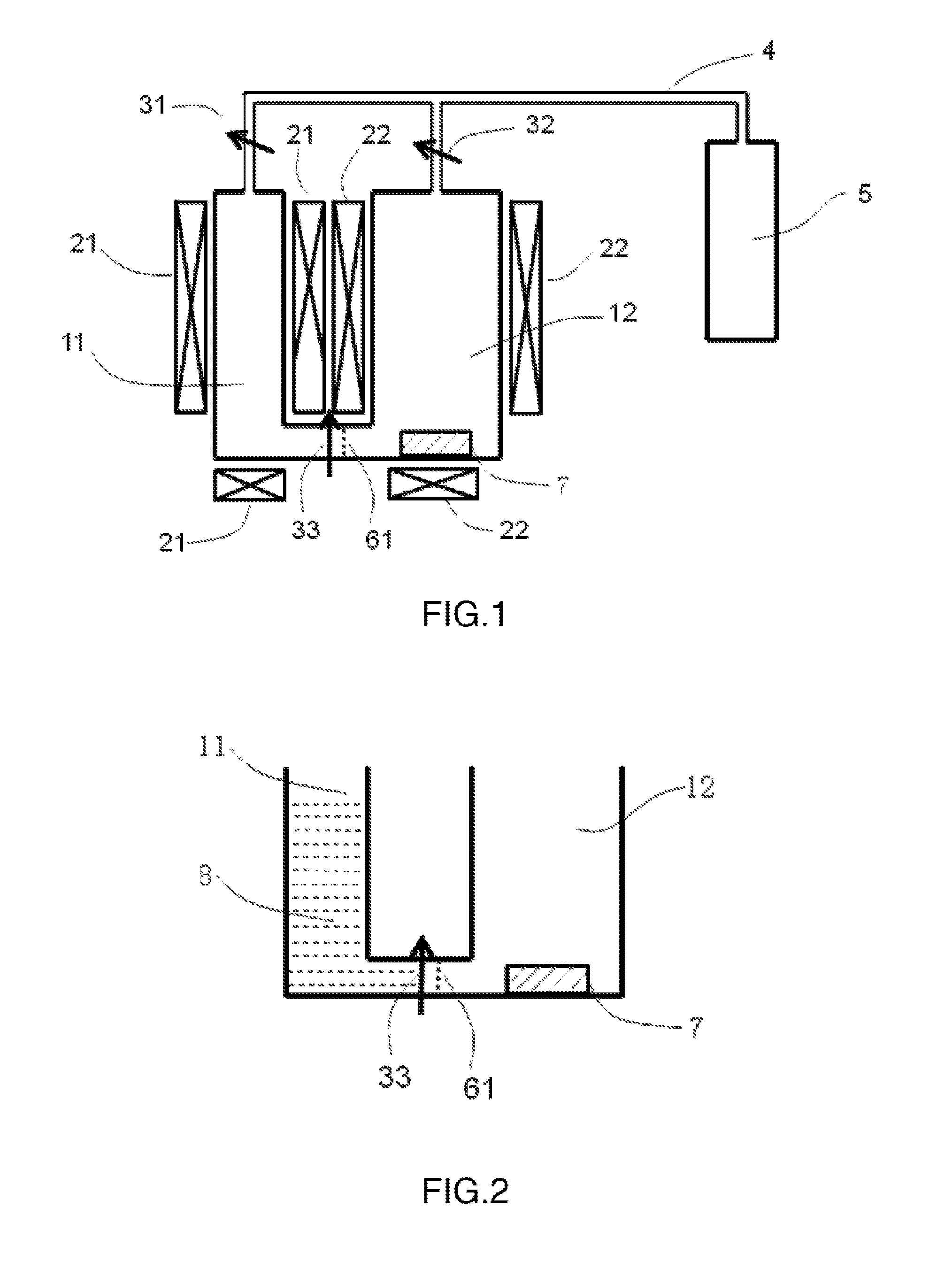

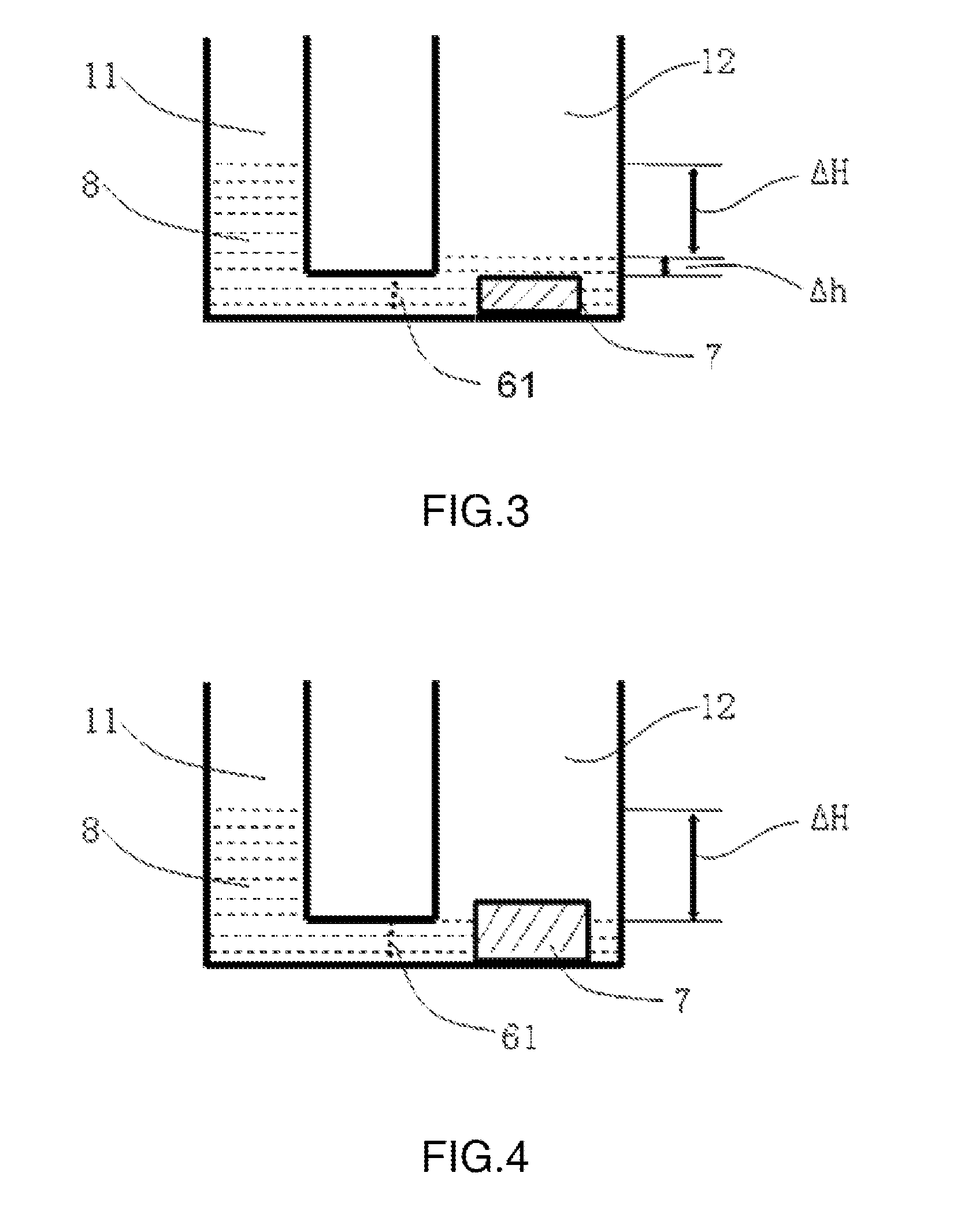

[0046]An apparatus for growing nitride bulk single crystal is a autoclave capable of withstanding high temperature and high pressure. The core structure of the autoclave comprises a crystal pre-growth chamber 11 and a crystal growth chamber 12 connected with each other. The crystal pre-growth chamber 11 is heated by a heating apparatus 21, and the raw materials such as nitrogen-containing reactants and the auxiliary pressure are controlled by a communication control apparatus 31. The crystal growth chamber 12 is heated by a heat source of a heating apparatus 22, and the raw materials such as nitrogen-containing reactants and the auxiliary pressure are controlled by a communication control apparatus 32. A gas storage tank 5 is a gas tank for storing the nitrogen-containing reactant and providing pressure control and N raw material in the growth process.

[0047]The exteriors of the outer side and the bottom of the crystal pre-growth chamber 11 are provided with a heating apparatus 21, t...

embodiment 2

[0053]In order to achieve the pre-growth conditions and flexible and efficient control of the growth conditions, the invention designs another novel autoclave apparatus structure and method for growing nitride bulk single crystal, as shown in FIG. 5. The core structure of the autoclave comprises three parts: a crystal pre-growth chamber 14, a crystal growth chamber 15 and a transition chamber 13. The crystal pre-growth chamber 14 and the crystal growth chamber 15 are connected with each other by the transition chamber 13. The transition chambers 13 can be orderly communicated, wherein the communication control apparatus 34 and the communication control apparatus 35 respectively control the separation and communication between the transition chamber 13 and the crystal pre-growth chamber 11, and between the transition chamber 13 and the crystal growth chamber 15. The crystal pre-growth chamber is a primary control zone for the conditions required by the reaction, and the crystal growt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com