Nanocomposite coating for antenna reflector and methods of making same

a technology of nanocomposite coating and antenna reflector, which is applied in nanotechnology, coatings, antennas, etc., can solve the problems of increasing the weight of antennas, reducing the payload of space stations, and metallic antennas being susceptible to electromagnetic interference, so as to enhance one or more electromagnetic characteristics of antenna reflectors and low weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

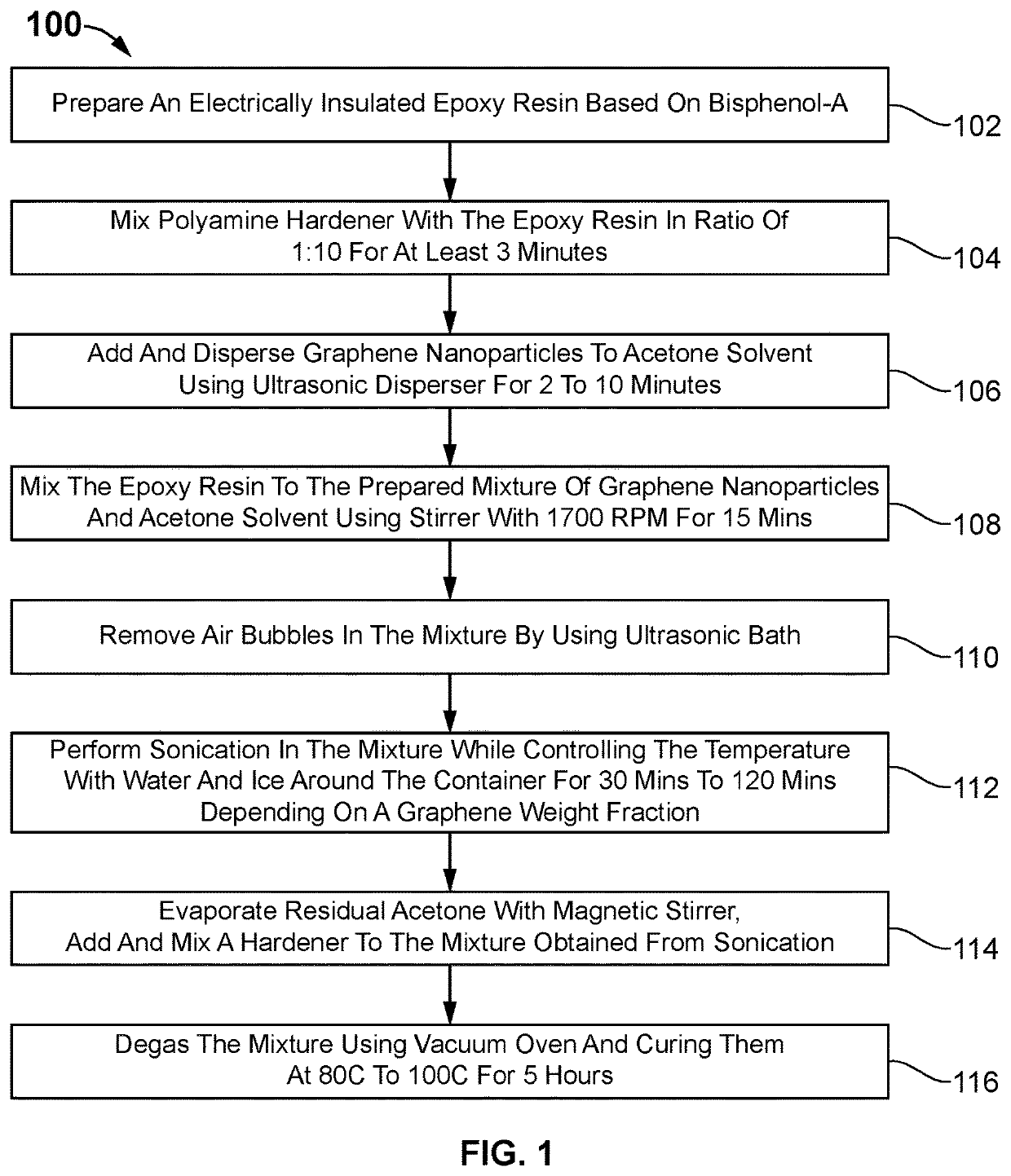

Method used

Image

Examples

example — 1

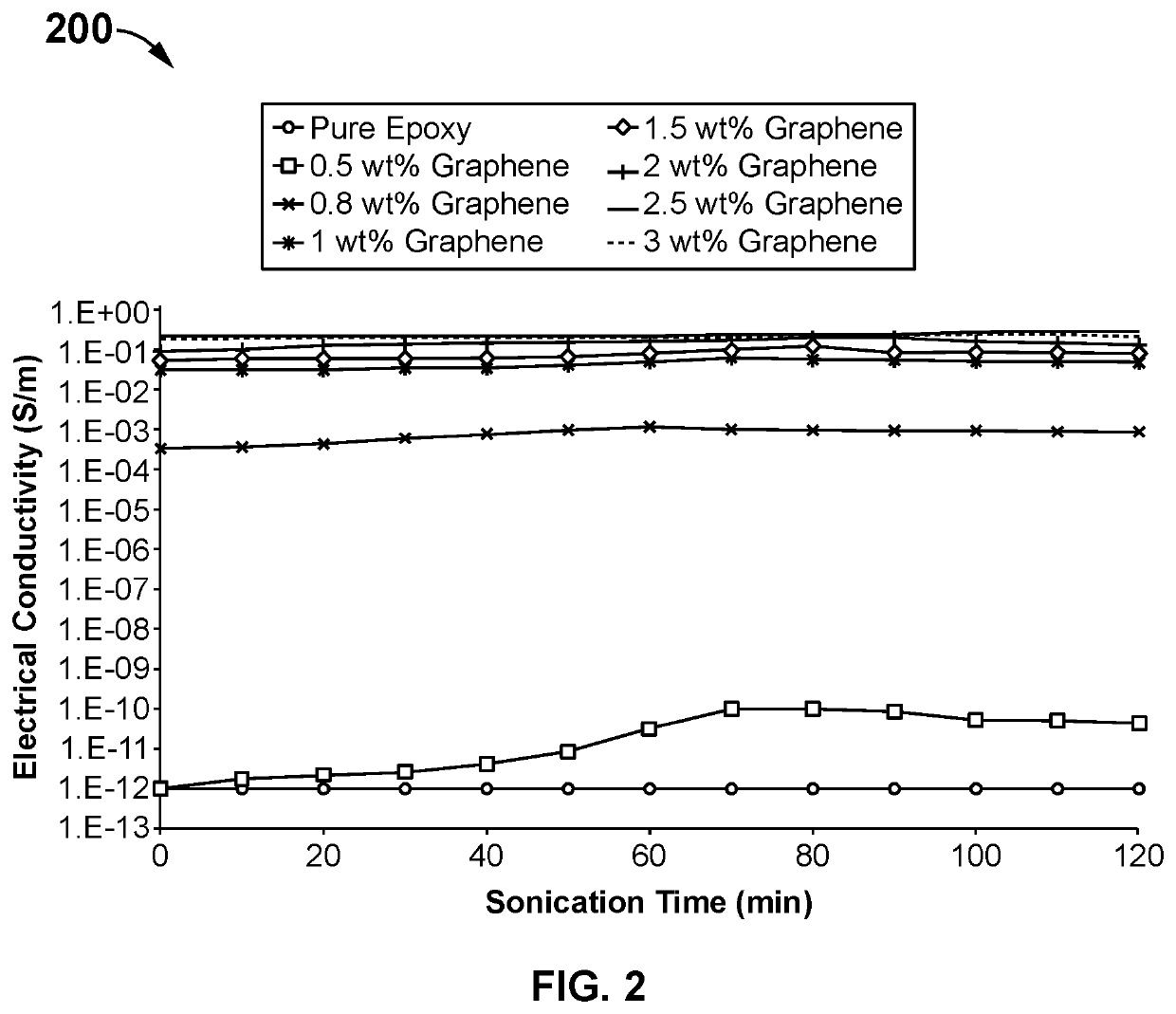

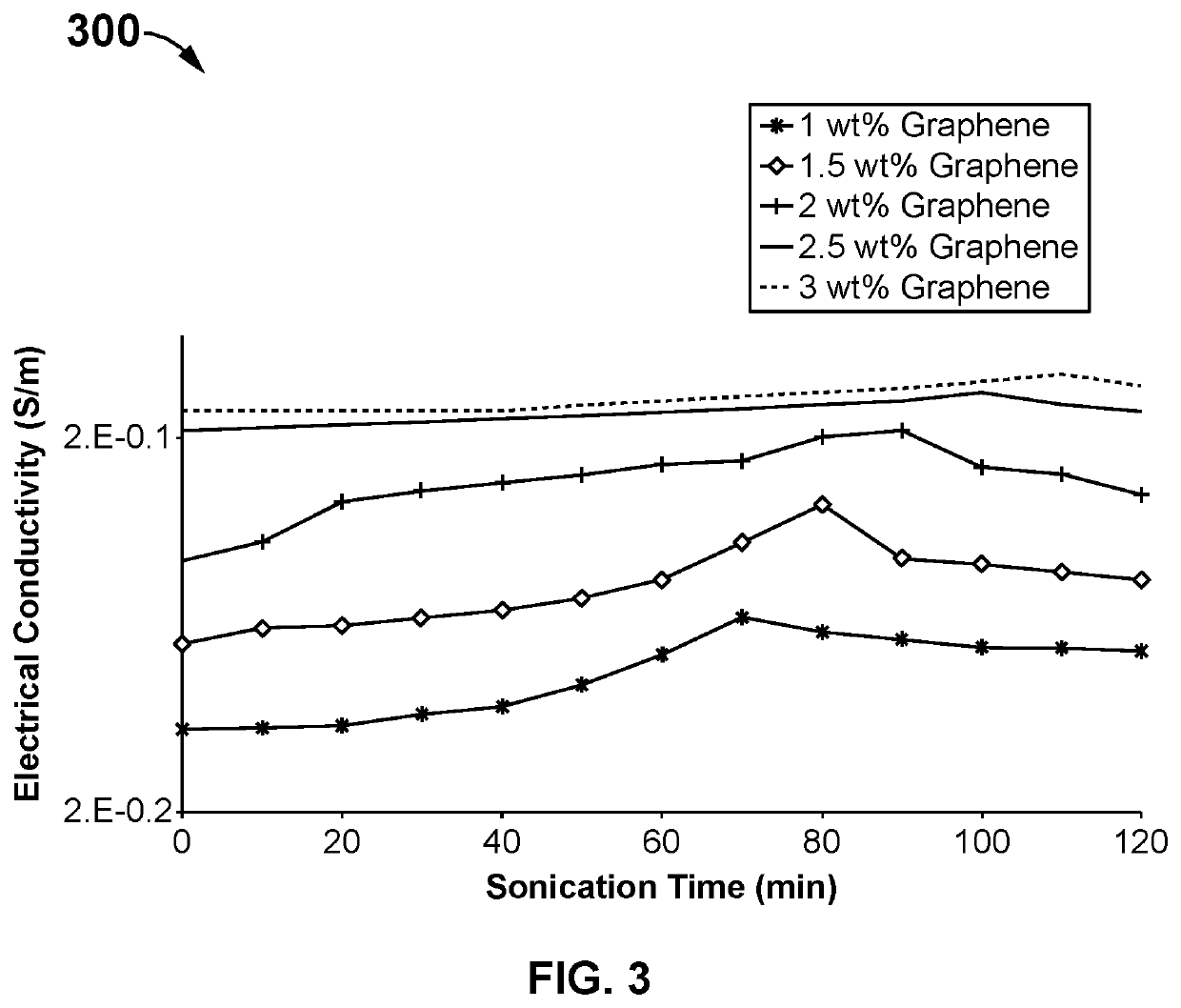

Example—1:—Electrical Conductivity

[0042]The electrical conductivity of the fabricated nanocomposite specimens is examined using a standardized four-point connection. A digital multimeter is employed to measure the current and resistance of the specimen / sample [2]. Upon the readings of the digital multimeter, the volume density is calculated using the equation (1). The volume density is used to calculate the electrical conductivity of the sample [2] using the equation (2):

ρ=RA / L (1)

σ=1 / ρ (2)

where “R” represents the electrical resistance (in Ω), “ρ” represents specific volume density (in Ωcm), “σ” represents DC electrical conductivity (in S / cm), “A” represents the area (in cm) and “L” represents the thickness of specimen (in cm).

example — 2

Example—2:—Permittivity

[0043]The performance of the materials in electromagnetic environments is characterized using the complex permittivity [3]. The relative permittivity comprises a real part of complex permittivity or dielectric constant or energy storage, and an imaginary part of complex permittivity or dielectric loss. The complex permittivity is expressed as below [4]:

εr=ε′+iε″ (3)

where εr represents complex relative permittivity, ε′ represents dielectric constant, and ε″ represents dielectric loss. The complex permittivity could be indirectly measured using scattering parameters with VNA (Vector Network Analyzer).

example — 3

Example—3:—Skin Depth

[0044]The skin depth describes the capability of the electromagnetic field emitted in a material and indicates the minimum required thickness for transmitting the electric current. The specimens having with a lesser thickness of skin depth provides a higher reflection rate. Hence, the current is transmitted to the upper layers of the specimens, which leads to the improvement in the electromagnetic properties of the material. Therefore, the electric conductivity of the material depends on the skin depth and the frequency of the applied waves. A perfect electric conductor has zero skin depth. For instance, the skin depth of a good electric conductor such as aluminum in Ku frequency band is about 0.736 to 0.611 μm. The Ku frequency band has a frequency range from 12.4 to 18 GHz with a relative permeability of one and resistivity of 2.65e-8. The skin depth is expressed in terms of frequency, electrical conductivity, and electromagnetic permittivity as below [5]:

δ−[ρ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com