Sprayed coating, method for manufacturing sprayed coating, sprayed member and spraying material

a technology of sprayed coating and spraying material, which is applied in the direction of superimposed coating process, rare earth metal fluoride, coating, etc., can solve the problems of high production cost, deterioration of process yield, and high production cost of type, and achieve low temperature dependence, good electric characteristics, and small variation of volume resistivities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0076]An A5052 aluminum alloy substrate having the surface size of 100 mm square and 5 mm thick was degreased at the surface by acetone, and one surface of the substrate was subjected to roughening treatment with an abrasive corundum. A yttrium oxide sprayed coating of 100 μm thick was formed as a lower layer on the substrate by using an atmospheric plasma spraying apparatus with a yttrium oxide powder (granulated particles) having an average particle size (D50) of 20 μm. As spraying conditions, argon gas and hydrogen gas were used as plasma gases, and output of 30 kW, and spraying distance of 120 mm were applied. The porosity of the lower layer was determined by image analysis method as explained below, and was 2.0%.

[0077]Further, a slurry was prepared such that 30 wt % of yttrium fluoride particles having a BET specific surface area of 0.7 m2 / g and an average particle size (D50) of 3.3 μm was dispersed in ethanol. A yttrium fluoride series sprayed coating of 150 μm thick was forme...

example 2

[0079]An A5052 aluminum alloy substrate having the surface size of 100 mm square and 5 mm thick was degreased at the surface by acetone, and one surface of the substrate was subjected to roughening treatment with an abrasive corundum. An erbium oxide sprayed coating of 100 μm thick was formed as a lower layer on the substrate by using an atmospheric plasma spraying apparatus with an erbium oxide powder (granulated particles) having an average particle size (D50) of 20 μm. As spraying conditions, argon gas and hydrogen gas were used as plasma gases, and output of 30 kW and spraying distance of 120 mm were applied. The porosity of the lower layer was determined by image analysis method as the same in Example 1, and was 3.2%.

[0080]Further, a slurry was prepared such that 30 wt % of erbium fluoride particles having a BET specific surface area of 1.5 m2 / g and an average particle size (D50) of 2.3 μm was dispersed in ethanol. An erbium fluoride series sprayed coating of 100 μm thick was f...

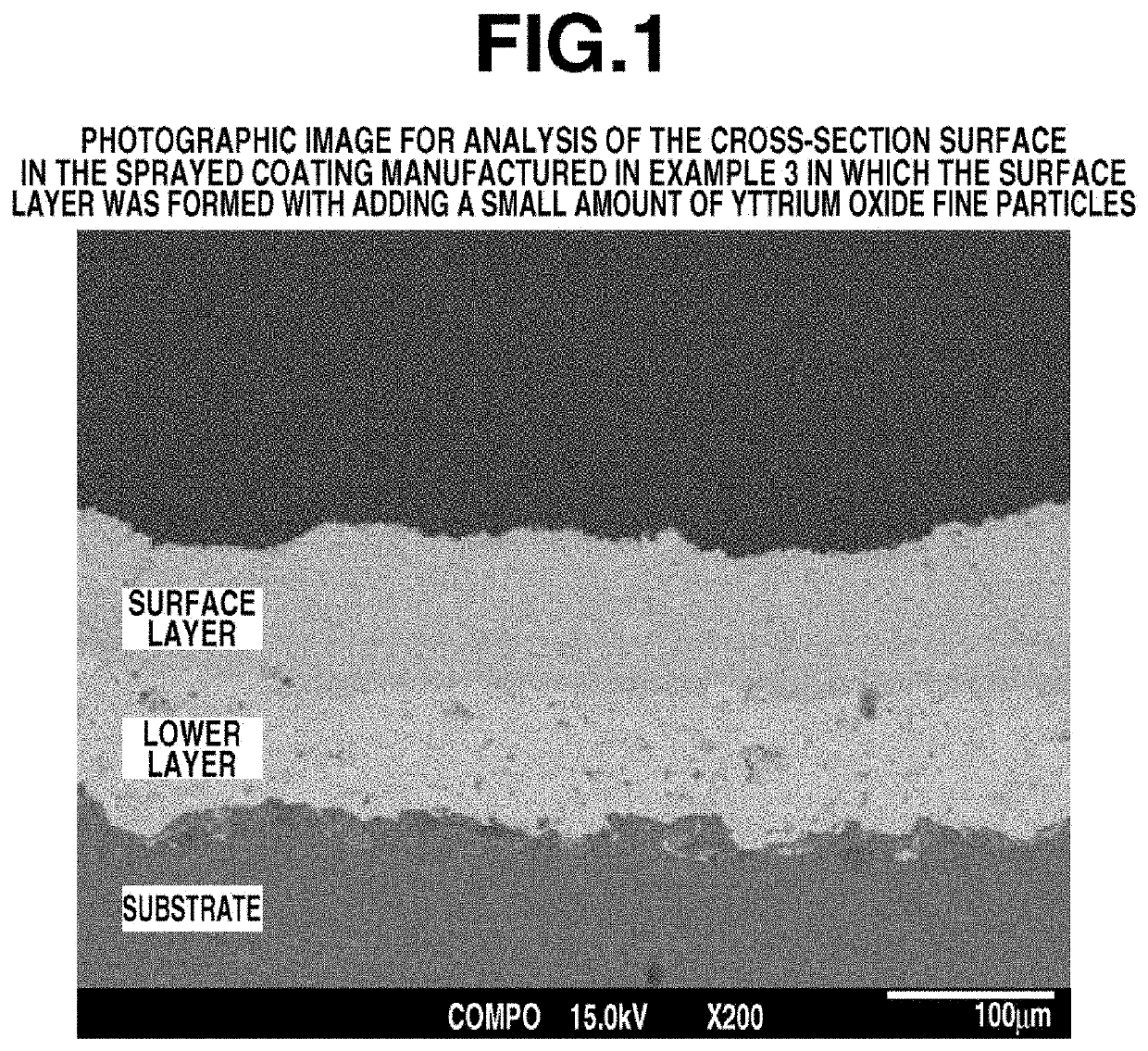

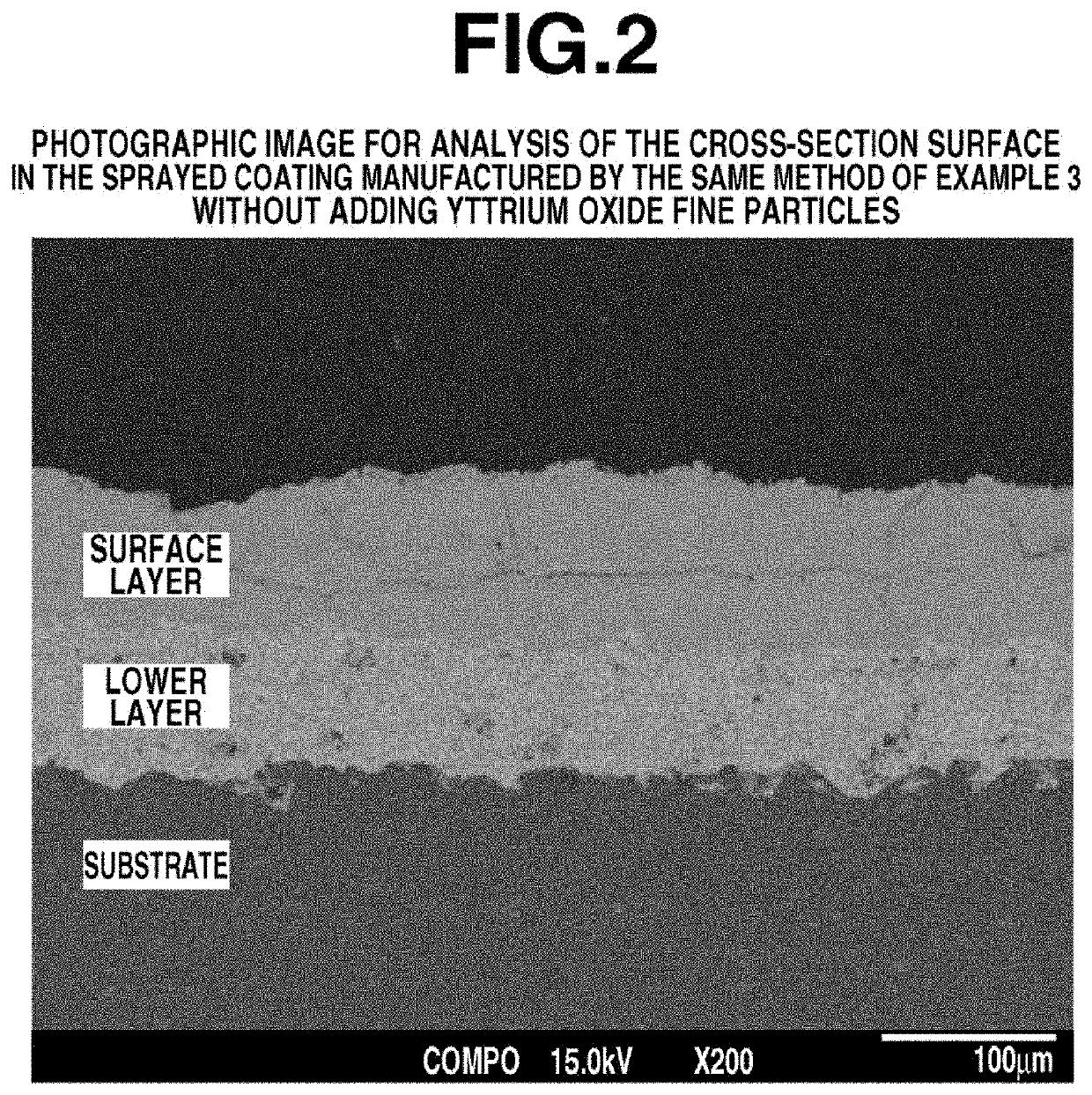

example 3

[0081]An A5052 aluminum alloy substrate having the surface size of 100 mm square and 5 mm thick was degreased at the surface by acetone, and one surface of the substrate was subjected to roughening treatment with an abrasive corundum. A yttrium oxide sprayed coating of 100 μm thick was formed as a lower layer on the substrate by using an atmospheric plasma spraying apparatus with a yttrium oxide powder (granulated particles) having an average particle size (D50) of 20 μm. As spraying conditions, argon gas and hydrogen gas were used as plasma gases, and output of 30 kW, and spraying distance of 120 mm were applied. The porosity of the lower layer was determined by image analysis method as the same in Example 1, and was 2.9%.

[0082]Further, a slurry was prepared such that 30 wt % of a mixture of yttrium fluoride particles having a BET specific surface area of 1.0 m2 / g and an average particle size (D50) of 3.7 μm, and yttrium oxide fine particles having a BET specific surface area of 48...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume resistivity | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com