Holographic sensors and their production

a technology of holographic sensors and production lines, applied in the direction of material testing goods, biochemistry apparatuses and processes, chemical methods analysis, etc., can solve the problems of limited application of gelatin to chemical sensing, unsuitable holographic film materials, and limited application of gelatin to holographic film materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

An Amylase Sensor

Starch gratings have the potential to be used as biosensors to detect the concentration of the digestive enzyme alpha-amylase in a body fluid. This can be vitally important as an indication of acute pancreatitis. However starch does not lend itself to the production of ultra-fine grain photographic emulsion when using the conventional technique with gelatin, because it causes severe grain growth before the gelation occurs.

Five steps are described for preparing and using the sensor. These are:

1. The treatment of glass to take a starch coating.

2. The preparation and coating of a layer of starch.

3. The introduction of a light-sensitive fine grain silver halide deposit in the pre-coated starch layer by a diffusion process.

4. Exposure and development to record an optical hologram.

5. Use of the starch hologram as a sensor for amylase.

Step 1

Presubbing coating:

Solution A

The powdered carbohydrates are added to the cold water and stirred on a heater until the temperature reac...

example 2

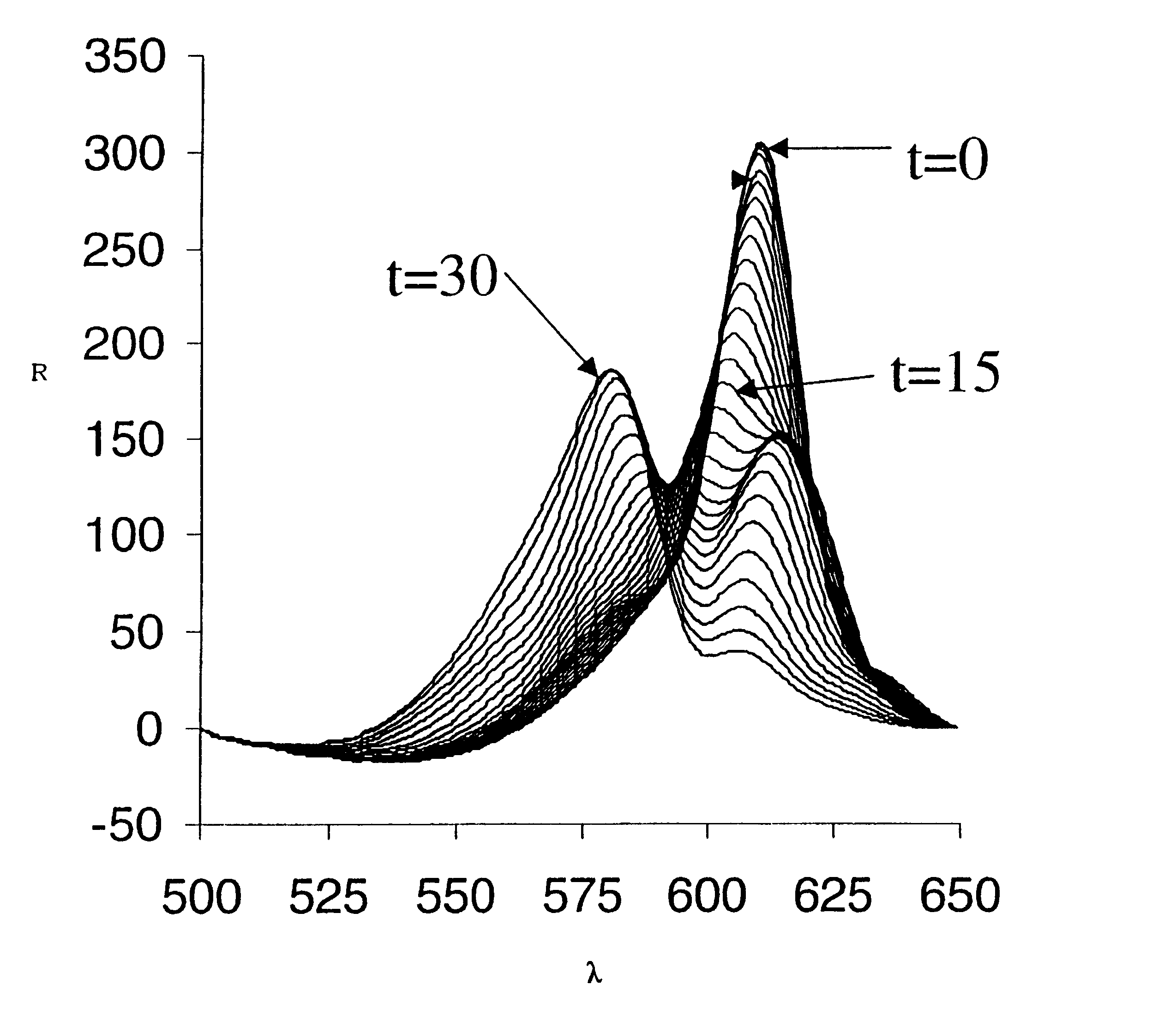

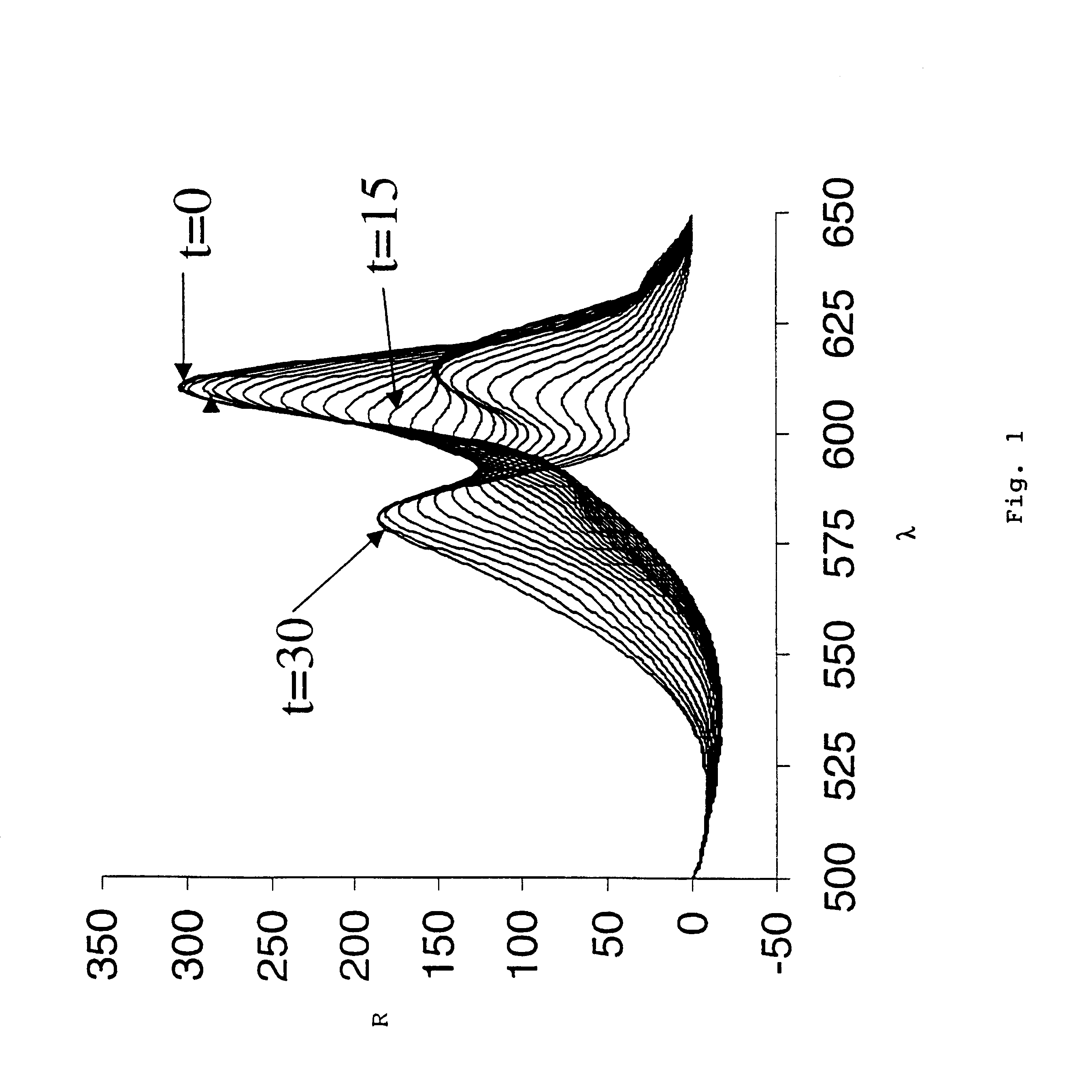

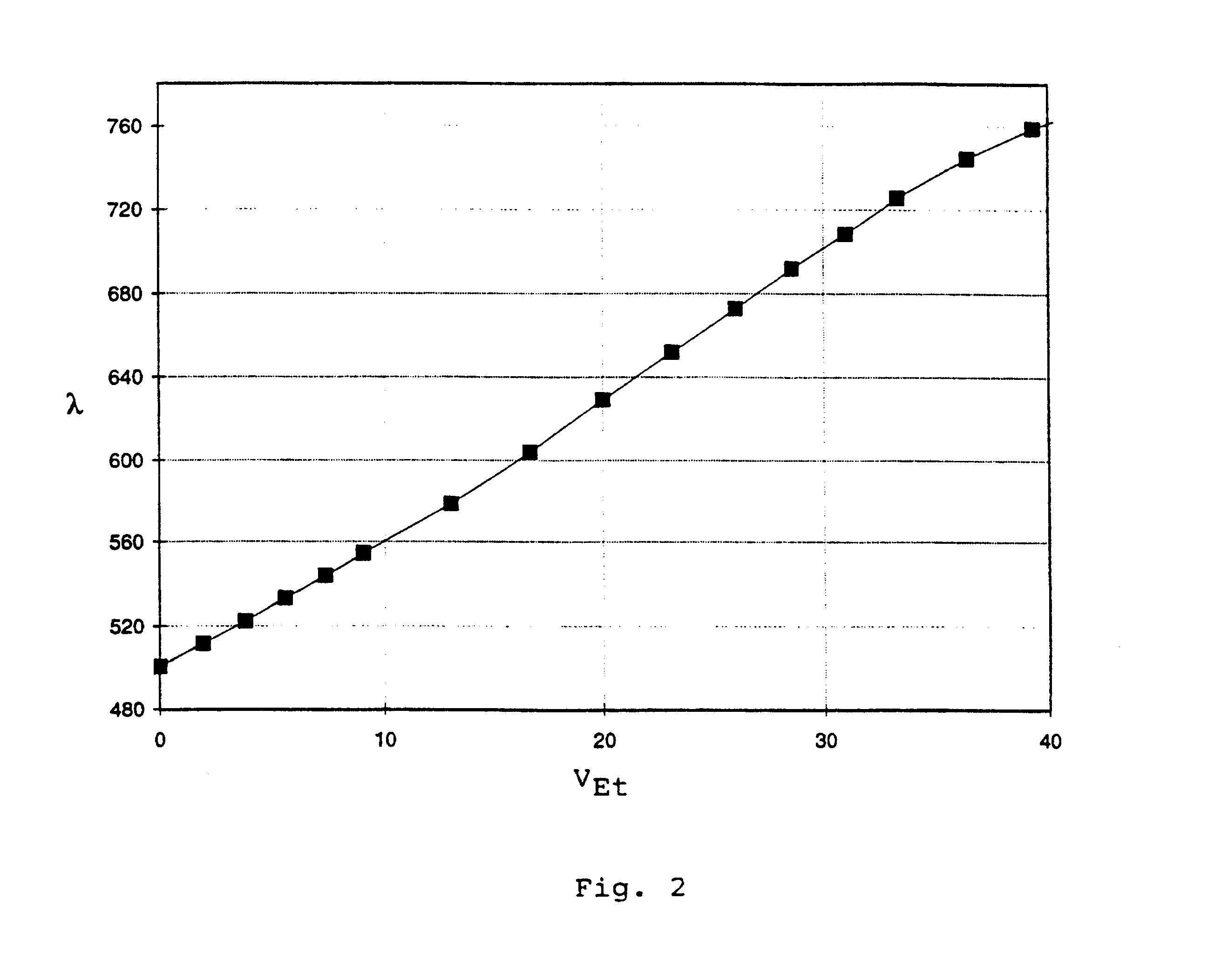

An Ethanol Sensor

A microscope slide is presubbed as follows: a 1% solution of 3-(trimethoxysilyl)propyl methacrylate in dry acetone is poured over it and left overnight to evaporate and hydrolyse on the glass surface. Excess silane is removed by washing with acetone before drying.

A solution of polymerizable monomers is prepared as follows:

100 .mu.l of this solution is poured onto a subbed slide (laid horizontally) and covered with an inert sheet of non-stick as high density polythene of the type used for transfer lettering (Letraset). The sandwich is then exposed to UV light through the glass side until fully polymerised. After removing the polythene cover sheet, the sample is rinsed in methanol and dried in a warm air flow.

The sample is treated with silver nitrate as for Example 1, but this time it is necessary for the 0.25 M silver nitrate to be in 50% water / 50% 2-propanol to enable it to readily penetrate the polymer. The slide is left in contact with the solution for an hour (ev...

example 3

Na / K Sensors

Sensors capable of measuring the concentration of sodium ions in the presence of potassium ions and vice versa are made.

The liquid solution is poured over a presubbed microscope slide and the same treatment is carried out as in Example 2, to produce a grating which can be cut to suit a spectrometer cuvette or mounted at the end of a fibre optic cable. Thus the silver grating is embedded in a copolymer of methacryloyl 12 crown 4 and HEMA in the approximate mole ratio of 60:40. Since the grating is subjected to high concentrations of salt solutions during preparation, it first requires extensive rinsing in several changes of de-ionized water for at least an hour before it can be used as a sensor.

FIG. 3a is a graph of cation concentration ([+]; mM) against wavelength shift (d.sub..lambda. ; nm). It contrasts the effects of sodium ions (.circle-solid.) and potassium ions (.tangle-solidup.) on the response of the hologram.

By the same general procedure, but using the converse ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com