Radiation sensitive resin composition

a technology of radiofrequency and resin composition, applied in the direction of photosensitive materials, instruments, photomechanical equipment, etc., can solve the problems of insufficient theoretical focal depth, large difficulty in fine processing of subhalf microns, and the performance of these resists approaching their limit, etc., to achieve excellent photolithographic process stability, high dry etching resistance, and high precision pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example 1

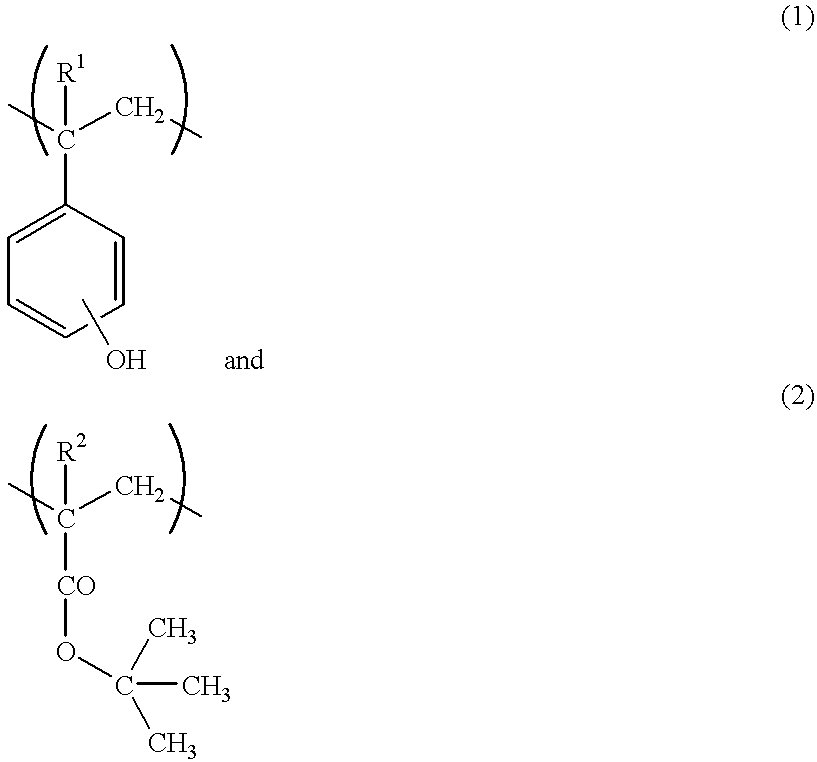

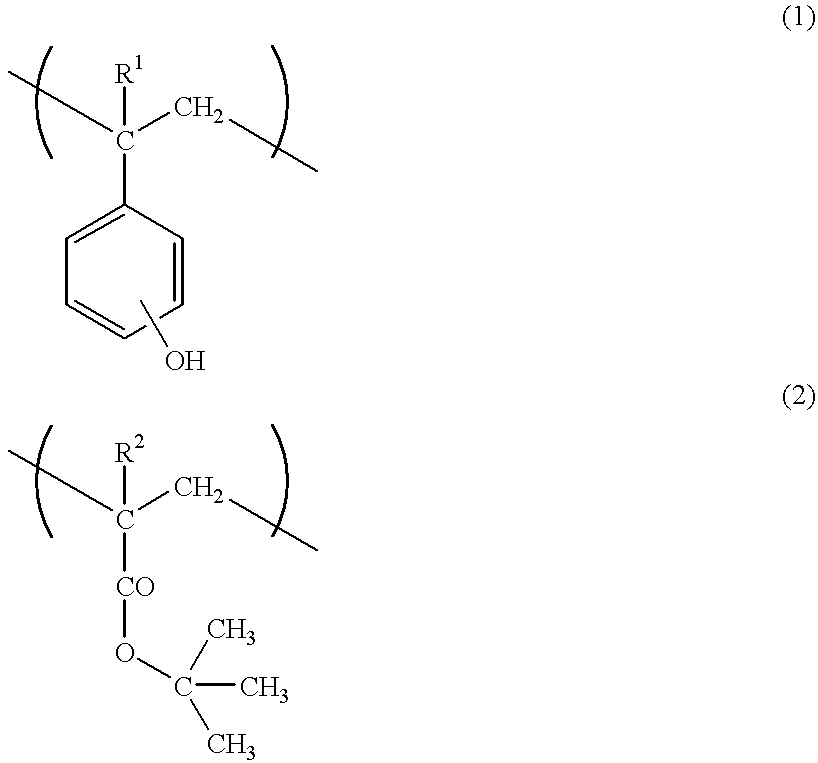

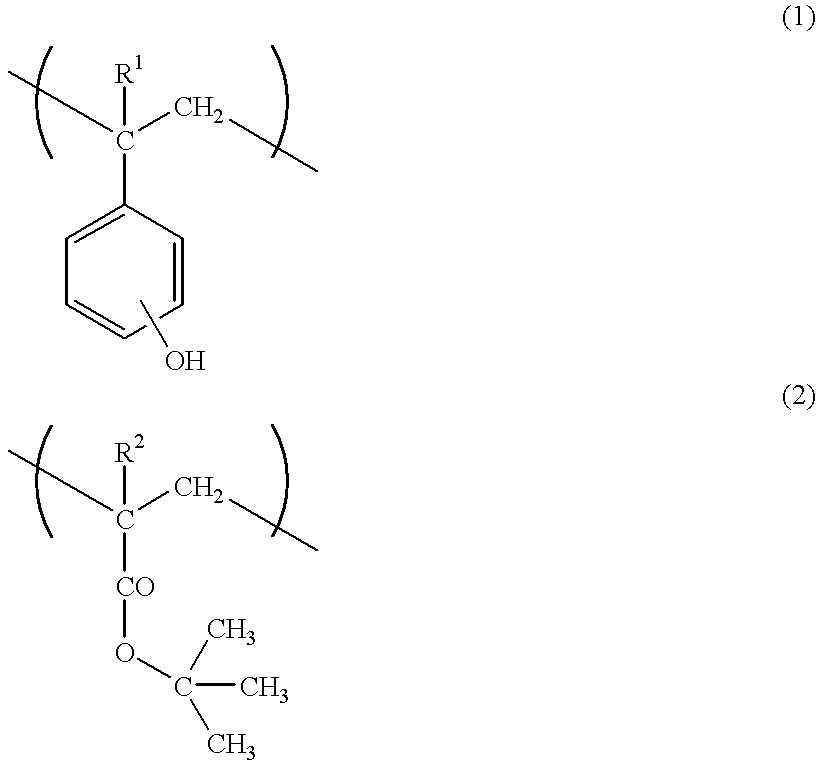

In 50 g of dioxane were dissolved 20 g of vinylphenol, 20 g of tert-butyl acrylate and 8.5 g of styrene, and then 8.2 g of 2,2'-azobisisobutyronitrile was added thereto, after which the resulting solution was bubbled with a nitrogen gas for 30 minutes. Thereafter, the solution was heated to 60.degree. C. while the bubbling was continued to effect polymerization for seven hours. After the polymerization, the solution was poured into a large amount of hexane to coagulate the polymer and the polymer was then recovered. The polymer was dissolved in acetone and then the resulting solution was poured into hexane again to coagulate the polymer. This operation was repeated several times to remove completely the unreacted monomers, after which the polymer was dried at 50.degree. C. under vacuum overnight. The polymer thus obtained was white and the yield was 55%. As a result of .sup.1 H-NMR and .sup.13 C-NMR analyses, it was found that the composition of the polymer was such that vinylphenol...

synthesis example 2

The same procedure as in Synthesis Example 1 was repeated, except that 22 g of isopropenylphenol was substituted for the 20 g of vinyphenol, to synthesize a polymer. The polymer obtained was white and the yield was 45%. As a result of .sup.1 H-NMR and .sup.13 C-NMR analyses, it was found that the composition of the polymer was such that isopropenylphenol, tert-butyl acrylate and styrene were copolymerized at a ratio of approximately 2:3:1. Mw was 28,000 and Mw / Mn was 2.6. This polymer is referred to hereinafter as Polymer (II).

synthesis example 3

The same procedure as in Synthesis Example 1 was repeated, except that 15 g of tert-butyl methacrylate was substituted for the 20 g of tert-butyl acrylate and 3 g of methyl methacrylate was substituted for the 8.5 g of styrene, to synthesize a polymer. The polymer obtained was white and the yield was 60%. As a result of .sup.1 H-NMR and .sup.13 C-NMR analyses, it was found that the composition of the polymer was such that vinylphenol, tert-butyl methacrylate and methyl methacrylate were copolymerized at a ratio of approximately 5:3:1. Mw was 22,000 and Mw / Mn was 2.7. This polymer is referred to hereinafter as Polymer (III).

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com