Paper making waste water disposal method by coagulant precipitation and coke filtration disposal

A papermaking industry wastewater, coagulation and sedimentation technology, applied in the direction of flocculation/sedimentation water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. High performance problems, to achieve the effect of low processing cost, simple process and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

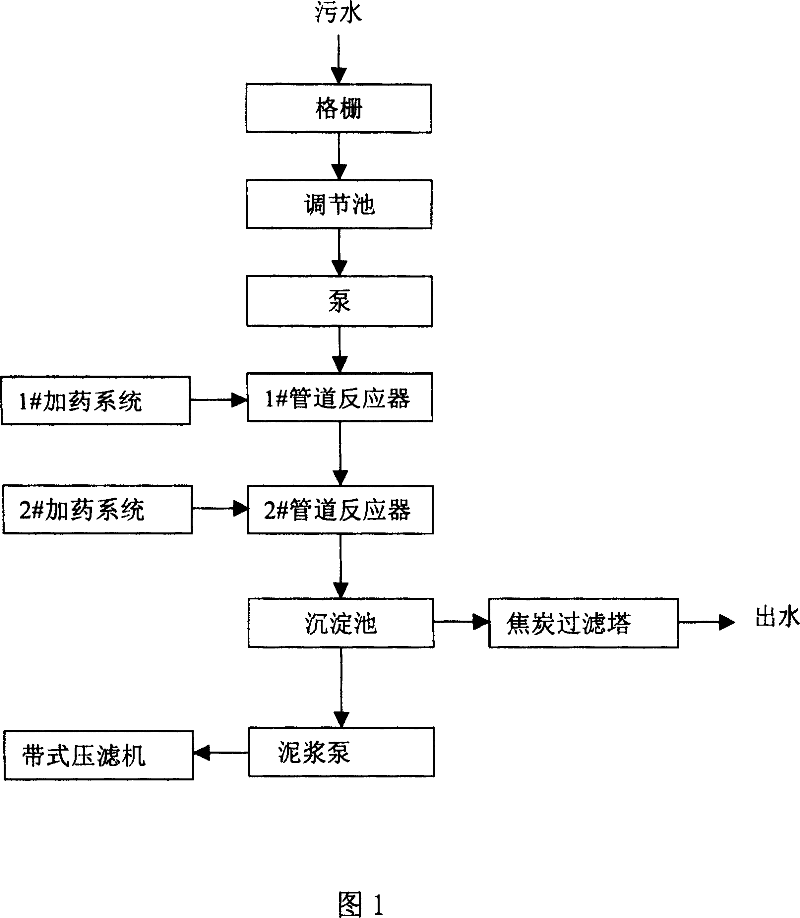

Image

Examples

Embodiment Construction

[0018] Example 1. Take 1000 mL of wastewater from an industrial paper mill, and use 1# dosing system to mix by weight. Based on 2000 mL of water, add 40 g of 95% aluminum sulfate and 10 g of 95% iron sulfate. 40g of 95% magnesium sulfate, 6g of 95% manganese sulfate, and 4g of Lithopone with a purity of 90% are formulated into a "sewage treatment agent" with a concentration of 5wt% (developed by the inventor, patented and authorized). When the wastewater passes through the 1# pipeline reactor, the amount of "sewage treatment agent" added is 6mL according to the weight of the wastewater. While the wastewater passes through the 2# pipeline reactor, a polyacrylamide solution with a concentration of 0.1 wt% prepared by the 2# dosing system is added, and the addition amount is 3 mL. The 1# and 2# pipeline reactors are all pipe reactors with left, right, and left spiral structures, which can make the passing waste water and medicament mix uniformly. The wastewater passing through the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com