Process for preparing biologically degradable reverse temperature sensitive material

A sensitive material and biological technology, which can be used in medical preparations containing active ingredients, drug delivery, pharmaceutical formulations, etc., can solve the problems of high injection temperature, high polymer concentration, affecting clinical application prospects, etc., and achieves a simple preparation process. , the effect of increasing hydrophobic interaction, good clinical application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

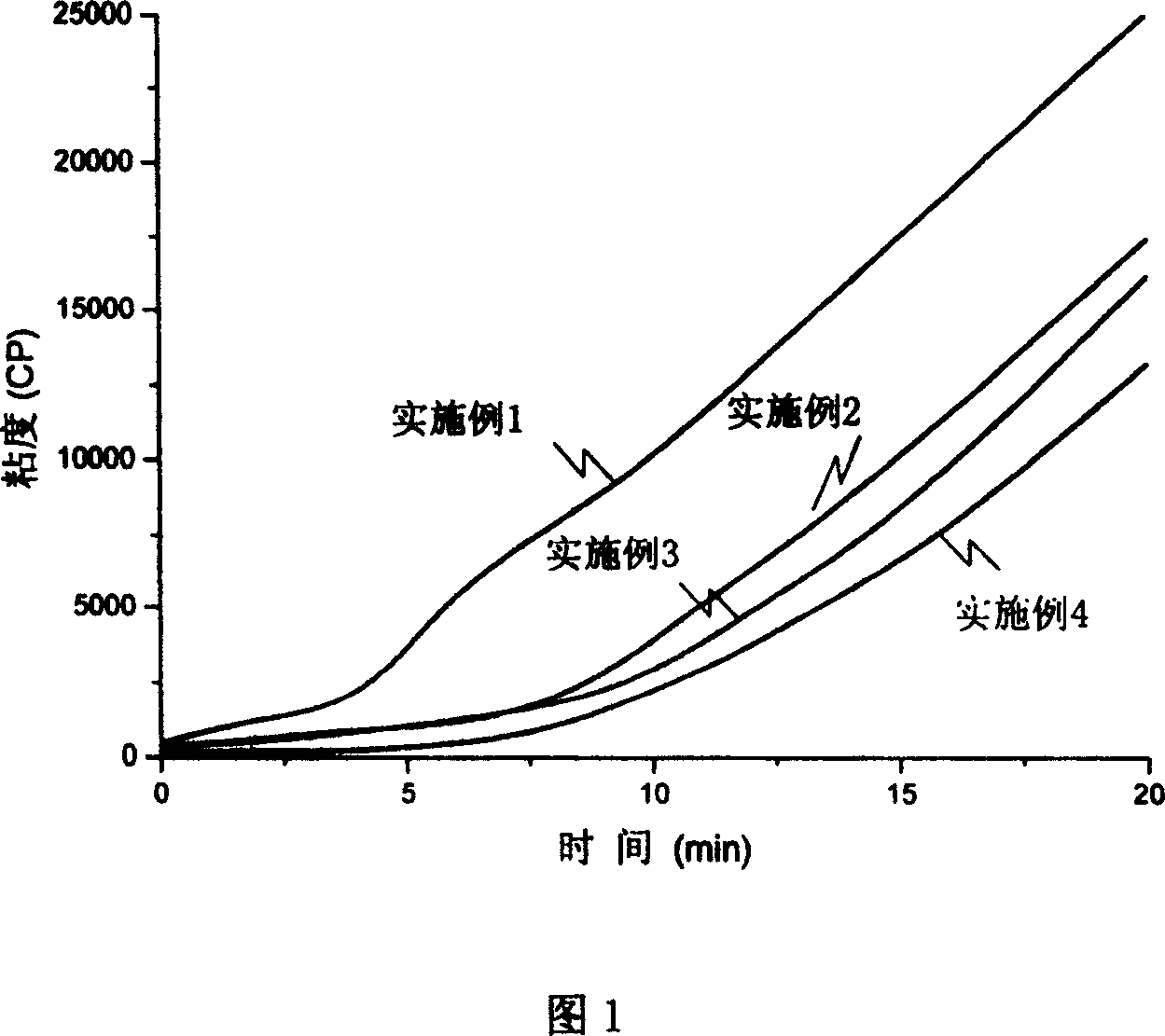

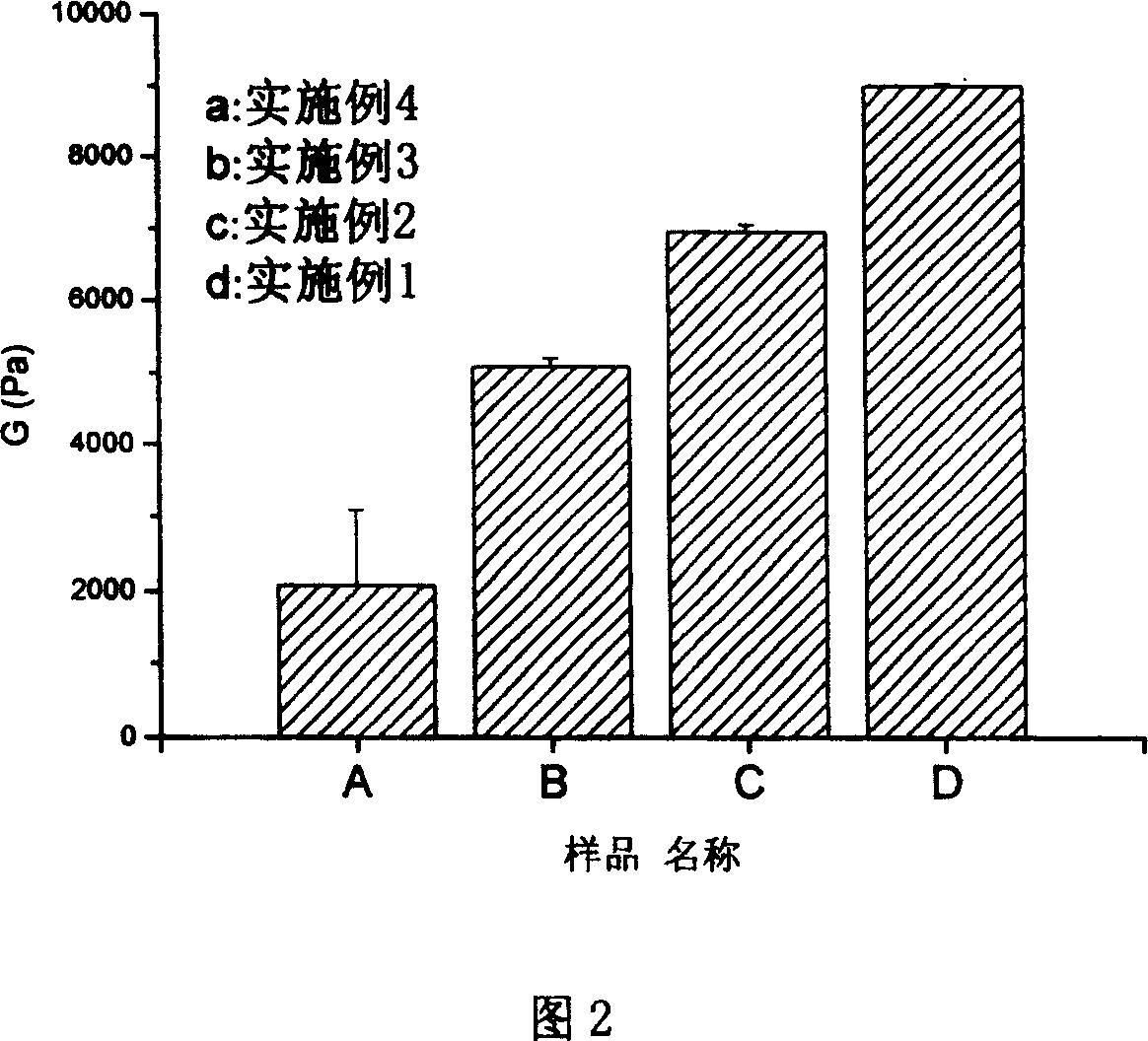

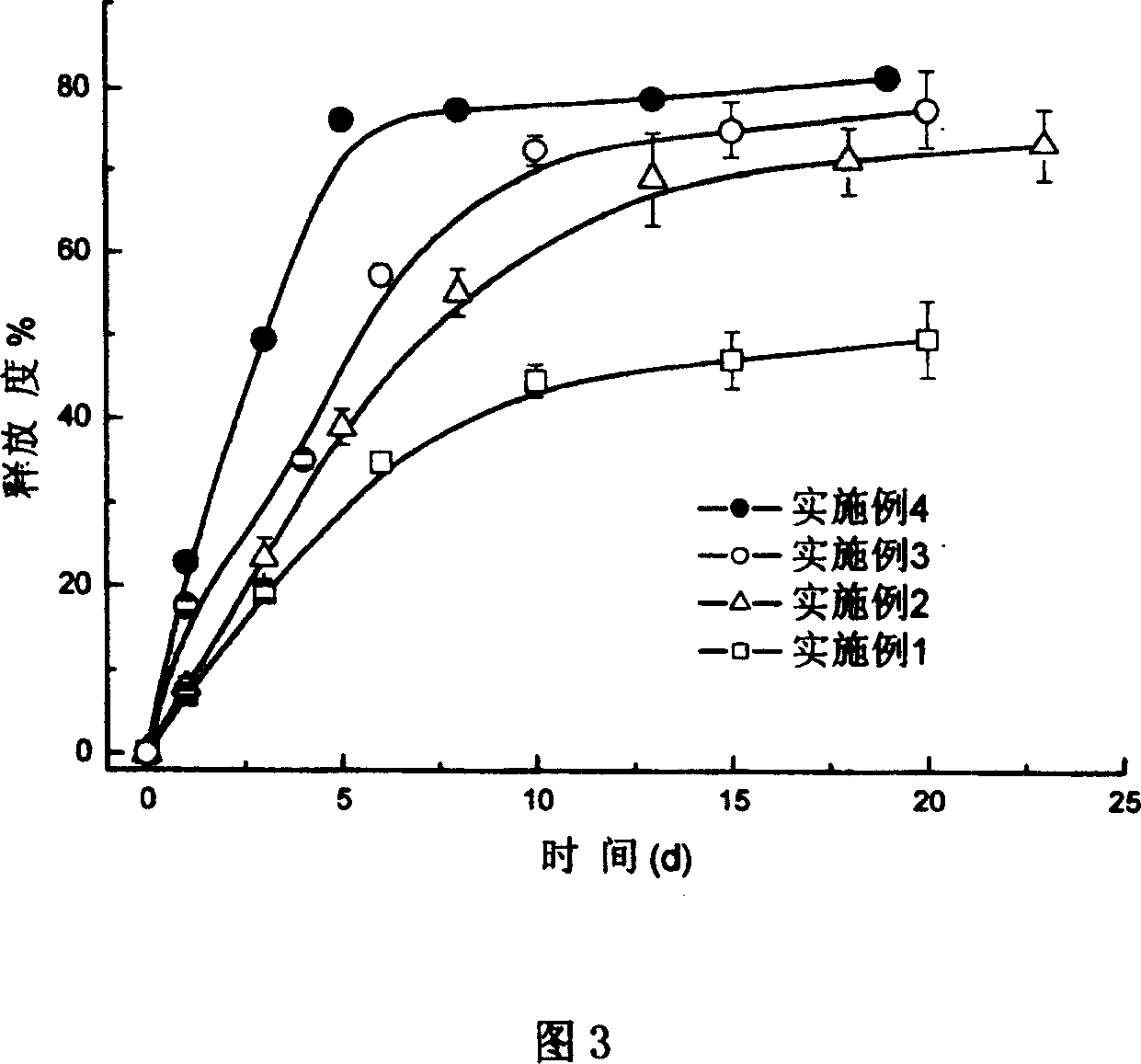

Embodiment 1

[0018] Dissolve the gelatin powder obtained by removing impurities in water to make a solution with a mass / volume concentration of 4%, filter and remove impurities for later use; add network penetration assistant polypropylene alcohol to the solution, and the mass ratio of gelatin to polypropylene alcohol is 1: 1. Heat at 70-80°C until completely dissolved, control the final mass / volume concentration of the system to 8.0%, cool to room temperature, and defoam; add epichlorohydrin dropwise while stirring until the final concentration is 100 μM; the cross-linking reaction is completed Finally, transfer to an ice-water bath, add a saturated aqueous solution containing sodium glucose phosphate, so that the final mass / volume concentration of sodium glucose phosphate is 10%, and take 30 to 60 minutes; slowly add a saturated aqueous solution of disodium hydrogen phosphate, adjust the pH to 7.4, and divide Assemble, do 3 groups of parallel experiments.

Embodiment 2

[0020] Dissolve the chitosan powder obtained from impurity removal in acetic acid solution to make a solution with a mass / volume concentration of 0.9%, filter to remove impurities for later use; add network penetration additive polyvinyl alcohol, chitosan and polyvinyl alcohol to the solution The mass ratio is 10:1, heated at 70-80°C until completely dissolved, the final mass / volume concentration of the control system is 1.0%, cooled to room temperature, defoaming; while stirring, add glutaraldehyde concentration dropwise to a final concentration of 0.1μM; After the cross-linking reaction is over, transfer to an ice-water bath, add a saturated aqueous solution containing sodium glycerophosphate until the final mass / volume concentration of sodium glycerophosphate is 15%, 30-60 minutes; slowly add saturated disodium hydrogen phosphate dropwise Aqueous solution, adjust the pH to 7.2, subpackage, and do 3 groups of parallel experiments.

Embodiment 3

[0022] Dissolve the xanthan gum powder obtained by removing impurities in water to make a solution with a mass / volume concentration of 0.2%, filter and remove impurities for later use; add network penetration additive polypropylene alcohol to the solution, the quality of xanthan gum and polypropylene alcohol The ratio is 1:10, heated at 70-80°C until it is completely dissolved, the final mass / volume concentration of the control system is 2.0%, cooled to room temperature, and defoamed; while stirring, add sodium polyphosphate dropwise to a final concentration of 1000 μM; After the cross-linking reaction is over, turn to an ice-water bath, add a saturated aqueous solution containing potassium fructose phosphate until the mass / volume concentration of potassium fructose phosphate is 0.5%, and take 30 to 60 minutes; slowly add a saturated aqueous solution of disodium hydrogen phosphate dropwise to adjust the pH to 7.4, subpackage, do 3 groups of parallel experiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com