Method and apparatus for calcining mineral materials difficult to be treated

A mineral material and difficult-to-handle technology, applied in the field of roasting method and equipment of mineral material, can solve the problems of high production cost, heavy pollution, low production capacity, etc., and achieve wide roasting temperature range, large usable area and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The present invention has carried out industrial roasting test on gold-containing refractory materials accumulated in the production of Zijin Mining Group Co., Ltd.

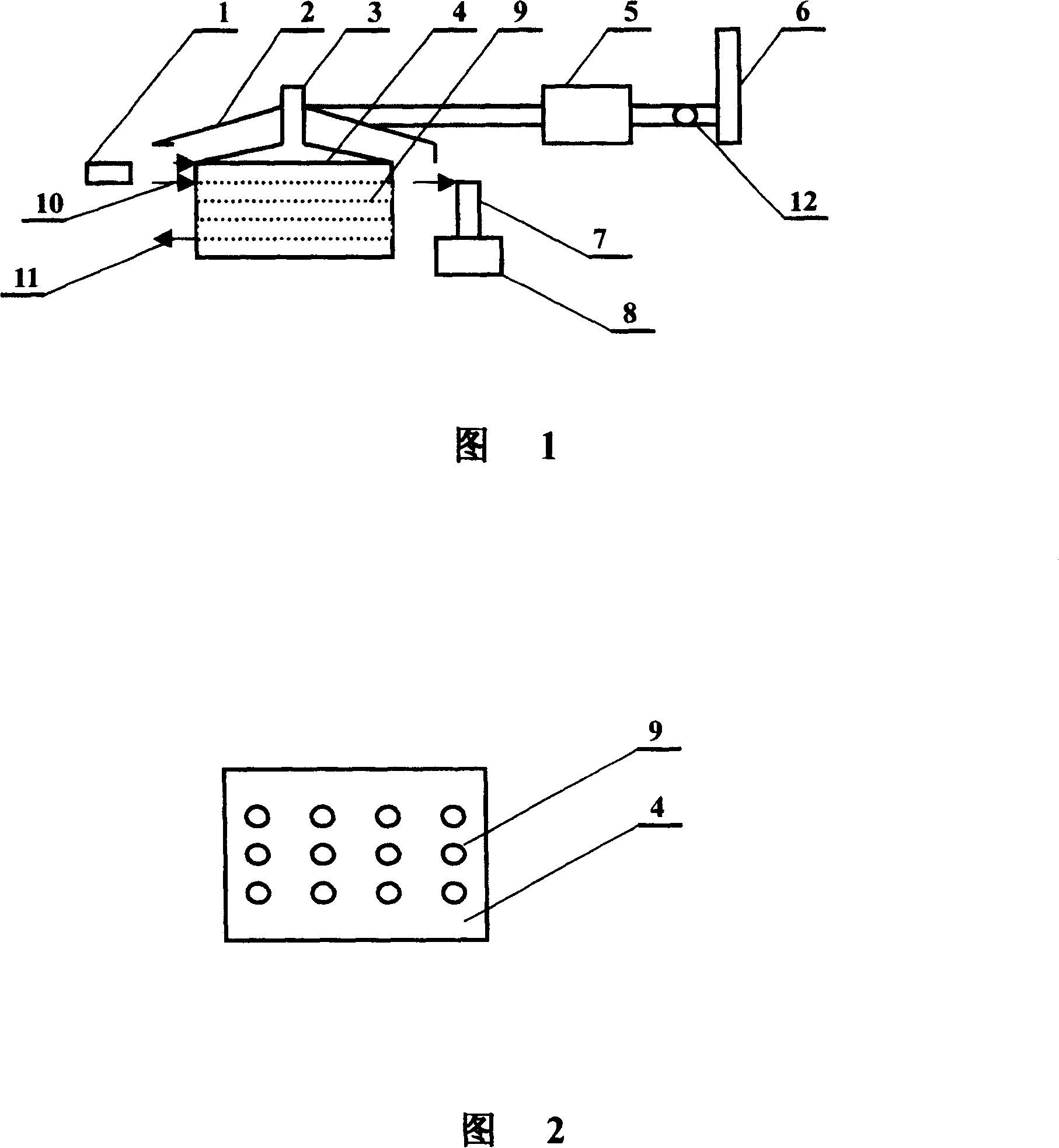

[0022] The multi-tube horizontal roasting furnace of the present invention's roasting method and equipment shown in Fig. 1 and Fig. 2 is composed of a feeder 1, a smoke collecting hood 2, a chimney 3, a body of furnace 4, a bag filter 5, and a washing machine. Composed of dust removal tower 6, receiver 7, water quenching pool 8, fueling device 10, fueling device 11 and induced draft fan 12, the furnace body 4 is an assembled horizontal cuboid with 60 horizontal parallel arrangements inside. The roasting tube 9, the length of the roasting tube is 2m, the inner diameter of the tube is 0.19m, and the total effective volume of the roasting tube is 2.76m 3 The chimney is located in the upper center of the furnace body, and the smoke collecting hood is set above the furnace body. The inlet covers b...

Embodiment 2

[0036] Example 2: Calcination of Coal Measures Kaolin Using Multi-Tube Horizontal Roasting Furnace

[0037]The multi-tube horizontal roasting furnace used is composed of a feeder, a smoke collecting hood, a chimney, a furnace body, a bag filter, a rinsing dust removal tower, a receiver, a fueling device, a fueling device, and an induced draft fan. It is an assembled horizontal cuboid with multiple horizontal parallel-arranged roasting tubes inside. The length-to-diameter ratio of the roasting tubes is 2-15:1; The inlet covers both ends of the inlet and outlet of the furnace body, the outlet is connected to the bag filter, and the bag filter is connected to the induced draft fan and the dedusting tower successively.

[0038] The main chemical composition of coal-measure kaolin is SiO 2 49.32%, AI 2 o 3 28.35%, and a small amount of carbonaceous and organic matter, the loss on ignition rate is 18.36%. The carbonaceous filling is cemented between and on the surface of kaolin ...

Embodiment 3

[0040] Example 3: Application of multi-tube horizontal roasting furnace to iron-containing dust and mud to produce iron oxide red

[0041] Iron-containing dust and sludge are solid wastes produced in the production process of iron and steel enterprises. Our country produces about 16 million tons annually. Returning them to sintering is the main method of comprehensive utilization in my country. However, due to the fine particle size and unstable composition of iron-containing dust and sludge, The return process is not conducive to production, and it is easy to cause re-pollution of dust and sludge. Therefore, the following test results are proposed for the rational and efficient use of iron-containing dust and sludge. Firstly, magnetic separation, flotation, gravity separation and its combined methods are used to enrich and remove iron-containing dust, and then dry oxidation roasting to obtain high-quality iron oxide red (containing F e2 o 3 98% or more).

[0042] The equipme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com