Non-plumbum series ferroelectric film with ingredient gradient distribution and its preparation method

A gradient distribution, ferroelectric thin film technology, applied in the field of non-lead ferroelectric thin film and its preparation, to achieve the effect of broadening the application range, improving the temperature characteristics, and improving the withstand voltage characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

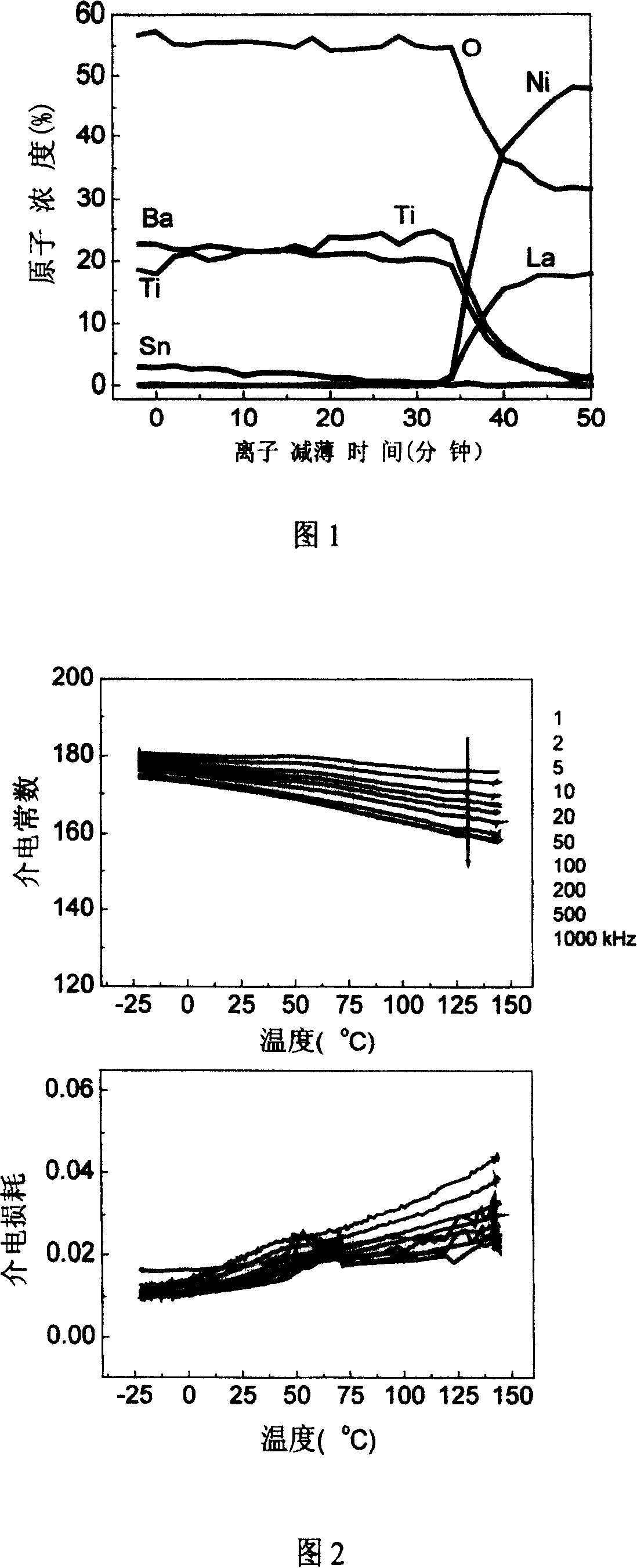

Embodiment 1

[0021] Preparation of Ba(Ti 1-x sn x )O 3 , x=0, 0.05, 0.10 and 0.15 composition gradient ferroelectric thin film:

[0022] The chemical raw material used is barium acetate [Ba(CH 3 COO 2 ], tin acetate [Sn(CH 3 COO) 4 ] and titanium isopropoxide [Ti(OC 3 h 7 ) 4 ], the solvent is glacial acetic acid and ethylene glycol ether. Firstly heat barium acetate and tin acetate (according to a certain stoichiometric ratio x=0.10) in glacial acetic acid solution to boiling, stop heating after 10 minutes, and cool to room temperature, the molar ratio of Ba+Sn to glacial acetic acid is 1: 10. Add the mixed solution of titanium isopropoxide, ethylene glycol ethyl ether and acetylacetone (AcAc) into the glacial acetic acid solution containing barium and tin, wherein: the molar ratio of Ti to AcAc is 1:2, titanium isopropoxide and The molar ratio of ethylene glycol ether is 1:10. Finally, ethylene glycol ether was added to adjust the concentration of the final solution to 0.3M. ...

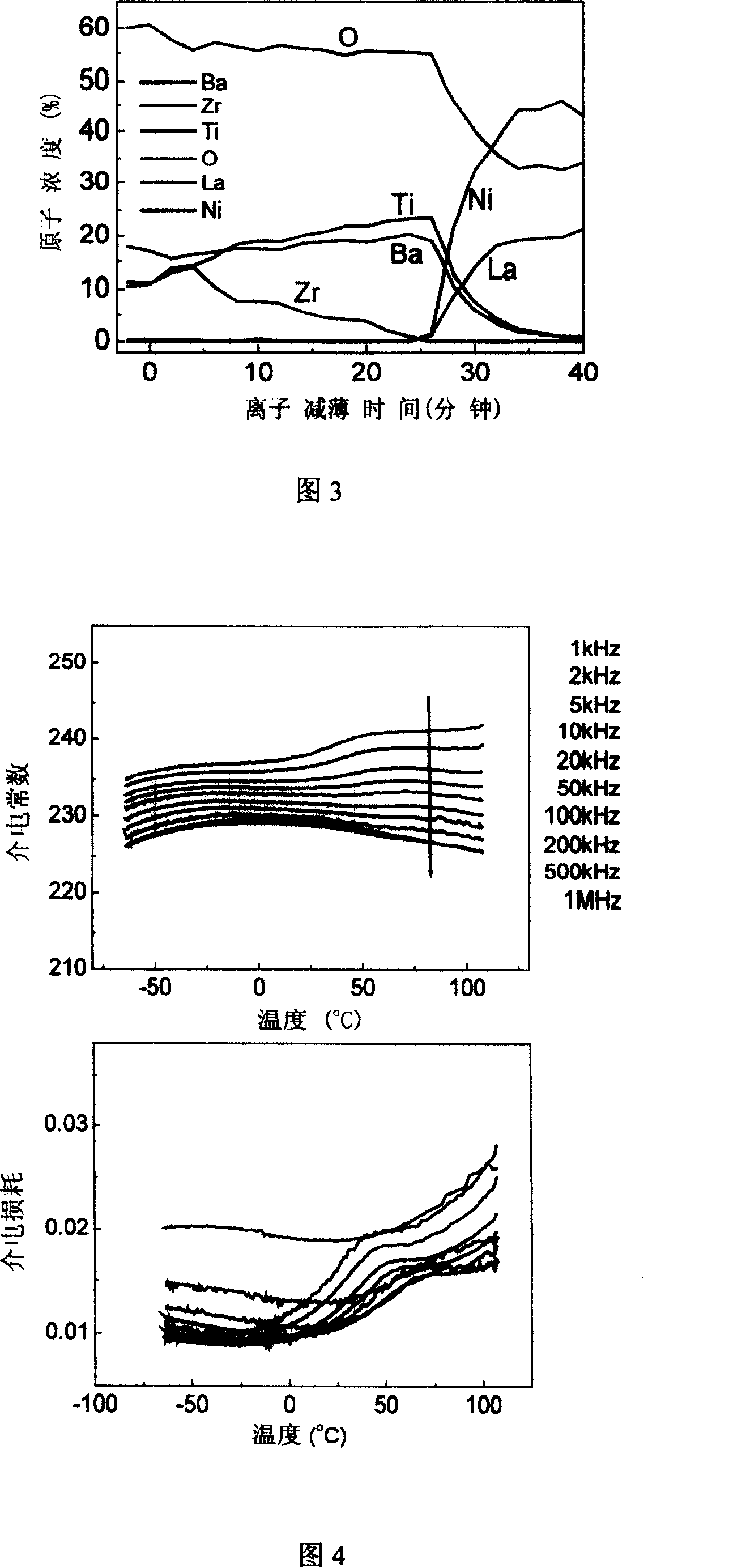

Embodiment 2

[0026] Preparation of Ba(Ti 1-x Zr x )O 3 , x = 0, 0.09, 0.18 and 0.35 composition gradient ferroelectric thin films:

[0027] The chemical raw material used is barium acetate [Ba(CH) 3 COO) 2 ], zirconium isopropoxide [Zr(OC 3 H 7 ) 4 ] and titanium isopropoxide [Ti(OC 3 H 7 ) 4 ], the solvent is glacial acetic acid and ethylene glycol ether. First, barium acetate (according to a certain stoichiometric ratio x=0.35) was heated to boiling in the glacial acetic acid solution, stopped heating after 5 minutes, and cooled to room temperature, and the molar ratio of Ba to glacial acetic acid was 1:10. Then add the mixed solution of zirconium isopropoxide and titanium isopropoxide, ethylene glycol ether and acetylacetone (AcAc) into the glacial acetic acid solution containing barium, wherein: the molar ratio of Ti and AcAc is 1:2, (iso The molar ratio of titanium propoxide + zirconium isopropoxide): ethylene glycol ether is 1:10. Finally, ethylene glycol ether was added ...

Embodiment 3

[0031] Preparation of Ba(Ti 1-x Zr x )O 3 , x = 0.15, 0.30, 0.50 and 0.70 composition gradient ferroelectric thin films:

[0032] The configuration method of the adopted chemical raw materials and the precursor solution is the same as that of Example 2. The substrate used is Pt / Ti / SiO 2 / Si. First use the precursor solution of x=0.70 on the substrate LaNiO 3 / Pt / Ti / SiO 2 3 coats on / Si, then 3 coats with x=0.50 precursor solution, 3 coats with x=0.30 precursor solution, and finally 3 coats with x=0.15 precursor solution, In this way, along the direction of film thickness, that is, along the direction from the film surface to the substrate, the content of zirconium gradually increases to form a lower gradient film. Each of the above layers is subjected to a heat treatment at 500°C for 5 minutes. Finally the film was heat treated at 650°C for 1 hour. Then, a gold electrode is sputtered on the upper surface by DC sputtering as the upper electrode, the diameter of which i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com