Method for preparing alkyl glycoside

A technology of alkyl glycosides and glucose, which is applied in the field of preparation of alkyl glycosides, can solve the problems of expensive metal borohydrides, unsuitable for industrial production, and high production costs, and achieve the effects of shortened reaction time, enhanced acidity, and improved reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In 100 liters of reactors, add 14kg of glucose (particle diameter 50 μm) containing one water of crystallization after ultramicronization treatment, C 8-10 Mixed fatty alcohols (which contain C 8 Alcohol 40%, C 10 Alcohol 60%) 56kg and ethyl sulfoacetate 240g, start stirring and heating, under 30mmHg vacuum degree, control the temperature in the still 50 ℃, maintain 0.5 hour. Then continuously increase the reaction temperature to 105°C, keep it for 1.5 hours, pass cooling water to reduce the temperature in the kettle to 80°C, add 230g of trisodium citrate, stir for 15 minutes, filter to obtain 210g of residue (sodium sulfonic acid salt), and the mother liquor is light Yellow alkyl glycoside alcohol solution.

[0029] Pour the above-mentioned alkyl glucoside alcohol solution into a distillation kettle or a thin film evaporator. Under a vacuum degree of 2mmHg, control the temperature in the kettle to 70-150°C, and distill the excess higher fatty alcohol. The distillatio...

Embodiment 2

[0032] In 100 liters of reactors, add 14kg of glucose (particle diameter 75 μm) containing a water of crystallization after ultramicronization treatment, C 8-10 Mixed fatty alcohols (which contain C 8 Alcohol 40%, C 10 Alcohol 60%) 56kg and ethyl sulfoacetate 240g, start stirring and heating, under 30mmHg vacuum degree, control the temperature in the still 50 ℃, maintain 0.5 hour. Then continuously increase the reaction temperature to 105°C, keep it for 1.5 hours, pass cooling water to lower the temperature in the kettle to 80°C, add 230 g of trisodium citrate, and stir for 15 minutes to obtain a light yellow alkyl glycoside alcohol solution.

[0033] Pour the above-mentioned alkyl glucoside alcohol solution into a distillation kettle or a thin film evaporator. Under a vacuum degree of 2mmHg, control the temperature in the kettle to 70-150°C, and distill the excess higher fatty alcohol. The distillation is completed in about 2 hours, and the temperature in the kettle The tem...

Embodiment 3

[0036] In 100 liters of reactors, add 14kg of glucose (particle diameter 150 μm) containing a water of crystallization after ultramicronization treatment, C 8-10 Mixed fatty alcohols (which contain C 8 Alcohol 40%, C 10 Alcohol 60%) 56kg and ethyl sulfoacetate 240g, start stirring and heating, under 30mmHg vacuum degree, control the temperature in the still 50 ℃, maintain 0.5 hour. Then continuously increase the reaction temperature to 105°C, keep it for 1.5 hours, pass cooling water to lower the temperature in the kettle to 80°C, add 230g of trisodium citrate, stir for 15 minutes, filter to obtain 810g of residue (sodium sulfonic acid salt), and the mother liquor is light Yellow alkyl glycoside alcohol solution.

[0037] Pour the above-mentioned alkyl glucoside alcohol solution into a distillation kettle or a thin film evaporator. Under a vacuum degree of 2mmHg, control the temperature in the kettle to 70-150°C, and distill the excess higher fatty alcohol. The distillation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

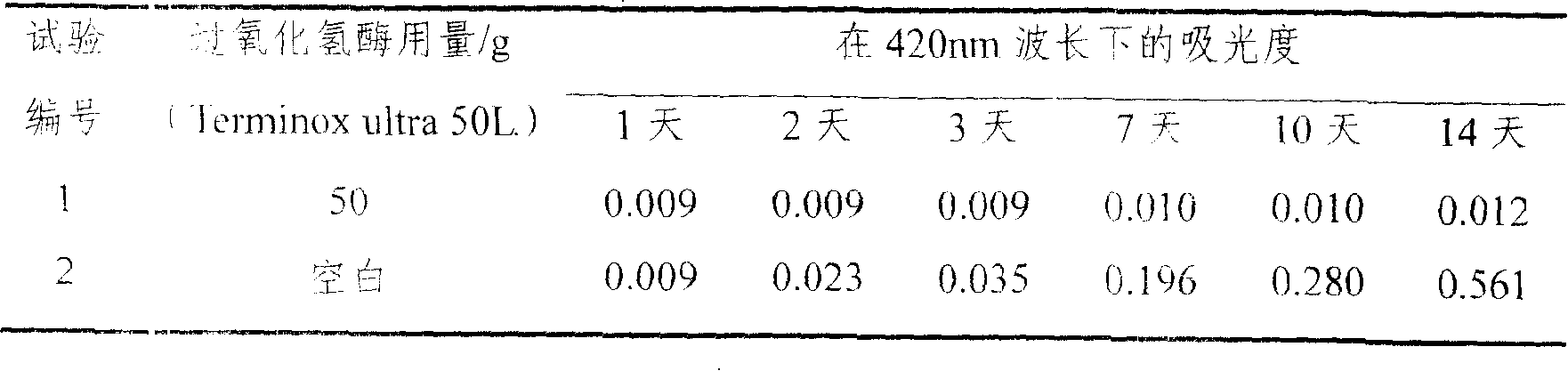

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com