Visible light responsible photocatalysis material of AgTO2 type composite oxide and its application

A technology of composite oxides and photocatalytic materials, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical/physical processes, etc., can solve low solar energy utilization rate and low quantum yield , can only work outdoors or in places with ultraviolet lamps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

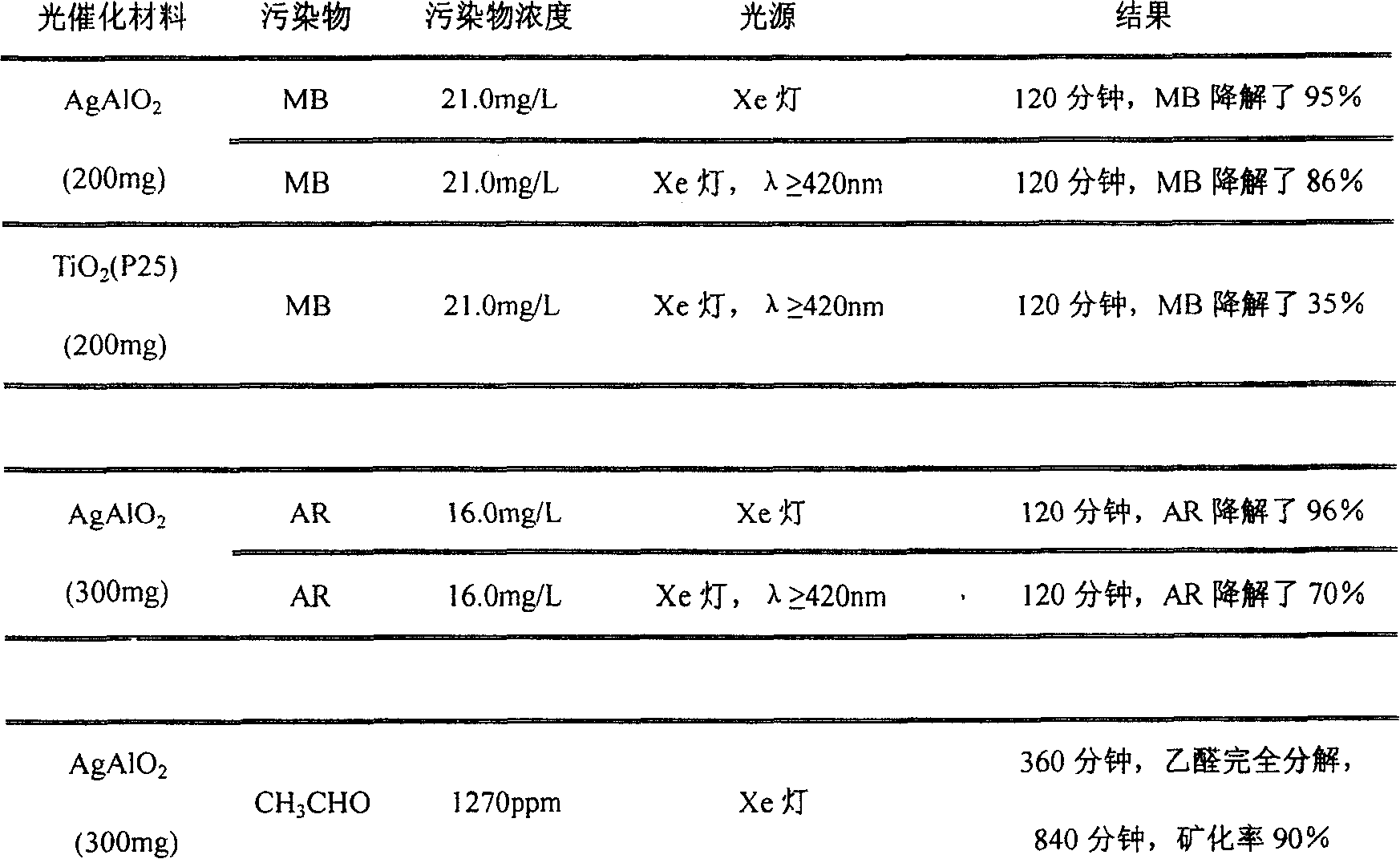

Examples

Embodiment 1

[0041] Preparation of AgTO by Ion Exchange Method 2 :

[0042] In the present invention, the ion exchange method is used to synthesize AgTO 2 (T=Al, Ga, In, Cr, Fe, Co, Ni), use raw material as follows (all are produced by Sinopharm Chemical Reagent Co., Ltd.): Li 2 CO 3 (99.99%), Al 2 o 3 (99.99%), Ga 2 o 3 (99.9%), In 2 o 3 (99.9%), Cr 2 o 3 (99.0%), Fe2 o 3 (99.0%), Co 2 o 3 (99.0%), NiO (99.0%), AgNO 3 (99.8%) and KNO 3 (99.0%). Preparing LiTO according to the stoichiometric ratio 2 (T=Al, Ga, In, Cr, Fe, Co, Ni): LiAlO 2 、LiCoO 2 Use Li 2 CO 3 with Al 2 o 3 or Co 2 o 3 Sintered at 900°C for 12 hours; LiGaO 2 , LiInO 2 , LiCrO 2 , LiFeO 2 Use Li 2 CO 3 with Ga 2 o 3 、In 2 o 3 、Cr 2 o 3 , Fe 2 o 3 Sintered at 750°C for 12 hours; LiNiO 2 Use Li 2 CO 3 Sintered with NiO at 650°C for 12 hours. The obtained precursor samples were mixed with AgNO 3 、KNO 3 Mix according to the molar ratio of 1:3:1, and then sinter at 275°C-400°C for 12 ...

Embodiment 2

[0044] AgTO 2 or AgTO 2 Preparation of M / AgTO by doping modified material as host material 2 , M x o y / AgTO 2 , M / (AgTO 2 doped modified material), M x o y / (AgTO 2 Doped modified material) composite material:

[0045] Get the AgTO prepared by 1g embodiment 1 2 Several parts of powder, take the prepared AgNO according to the loading capacity 3 (1g / 100ml), Bi(NO 3 ) 3 ·5H 2 O(1g / 100ml), Ni(NO 3 ) 2 ·6H 2 O(1g / 100ml), Zn(NO 3 ) 2 ·6H 2 O (1g / 100ml), H 2 PtCl 6 ·6H 2 O (1g / 100ml), RuCl 3 ·3H 2 O (1g / 100ml) and other salt solutions, the AgTO 2 The powder is mixed with salt solution and ground for half an hour, and dried in an oven. To prepare M / AgTO 2 For composite materials (M=metal), place the powder in a tube furnace at 300-1200°C (different sintering temperatures are used according to the decomposition temperature of the above-mentioned salts), sinter in an air atmosphere for 3-12 hours, and then sinter in a hydrogen atmosphere. Sintering under reduc...

Embodiment 3

[0048] AgTO 2 Thin film doctor blade method (Doctor Blade Method) preparation and AgTO 2 Surface coating layer preparation:

[0049] In the preparation of AgTO 2 For thin films, take a small amount of AgTO prepared in Example 1 2 (T=Al, Ga, In, Cr, Fe, Co, Ni) Add 2-4 drops each of polyvinyl alcohol and acetylacetone to the powder, mix to form a slurry, and directly use the doctor blade method (Doctor Blade Method) to mix the slurry Coat the substrate (20mm×20mm) and sinter at 400°C for 2-5 hours to produce a film. Weigh the substrate and the substrate with the film to obtain the weight of the film layer, which is about 10mg-30mg.

[0050] When preparing the surface coating layer, take 100mg of AgTO 2 (T=Al, Ga, In, Cr, Fe, Co, Ni) powder, suspended in 100ml of water or organic solvent, the suspension is divided into 3-5 times and all sprayed on the surface of building materials (1m 2 ), an annealing treatment at 300-1000°C (different temperatures are used depending on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com