Antibiosis layered board and preparation method thereof

A composite board and resin technology, which is applied in the direction of botany equipment and methods, chemical instruments and methods, and synthetic resin layered products, can solve the problems of limited application range and lack of antibacterial properties, and achieve good social and economic benefits. Antibacterial performance preparation process, effect of antibacterial effect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] In this embodiment, silver oxide is selected as the antibacterial agent. First, the antibacterial agent silver oxide is pretreated with a coupling agent, and is mixed with a diluent petroleum ether and an organic silicon coupling agent KH560 to form a paste. The organic silicon coupling agent KH560 accounts for 1% by weight of silver oxide, at room temperature, pulverized in a ball mill for 30 minutes, and mixed uniformly.

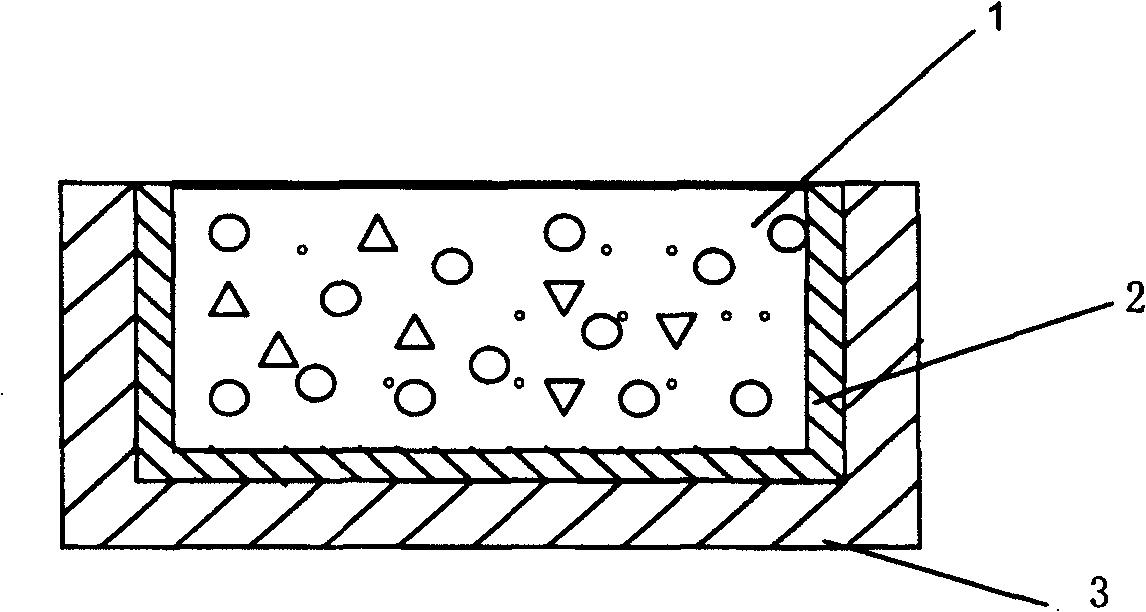

[0021] see attached figure 1 , prepare a kind of antibacterial composite board with hydraulic cementitious material as the base layer, polymer concrete as the transition layer, and polymer material as the covering layer, the method is: the weight ratio of the mixed resin of phenolic resin and epoxy resin is 1 : 1. 400 mesh talc, carbon black, flame retardant ammonium polyphosphate, glass fiber, flame retardant hexabromocyclododecane, antibacterial agent silver oxide by weight of 100: 120: 1: 30: 1: 10: 3 Mix and stir evenly, then add the curing age...

Embodiment 2

[0026] In this embodiment, silver phosphate is selected as the antibacterial agent, and the antibacterial agent silver phosphate is first subjected to hyperdispersion pretreatment, and is mixed with diluent acetone and hyperdispersant to form paste. The hyperdispersant accounts for 1.5% of the weight of silver oxide, and the room temperature Condition, pulverize in a ball mill for 60 minutes to make it evenly mixed.

[0027] see attached figure 1 , prepare a kind of antibacterial composite board with hydraulic cementitious material as the base layer, polymer concrete as the transition layer, and polymer material as the covering layer, the method is: mixing unsaturated resin and epoxy resin resin, and its weight ratio is 1:1, 500 mesh kaolin, iron yellow, flame retardant ammonium polyphosphate, polypropylene fiber, flame retardant brominated epoxy resin, antibacterial agent silver phosphate by weight of 100:100:1:40:1:20:3 After mixing the proportions, stir evenly, then add th...

Embodiment 3

[0032] In this embodiment, silver zeolite is selected as the antibacterial agent, and the antibacterial agent silver zeolite is firstly subjected to hyperdispersion pretreatment, and the silver zeolite is mixed with toluene and the hyperdispersant to paste, and the hyperdispersant accounts for 2% of the weight of the silver zeolite. Grind in a ball mill for 60 minutes.

[0033] see attached figure 1, prepare a kind of antibacterial composite board with hydraulic cementitious material as the base layer, polymer concrete as the transition layer, and polymer material as the covering layer, the method is as follows: the mixed resin of phenolic resin and unsaturated resin is used, and its weight ratio is 1:1, 400 mesh calcium carbonate, chrome yellow, flame retardant magnesium hydroxide, polybutadiene glycol, flame retardant chlorinated paraffin-70, antibacterial agent silver zeolite according to 100:120:1:30:5 After mixing in a weight ratio of 15:3, stir evenly, then add dimethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com