Method of preparing yttrium aluminium garnet fluorescent powder

A technology of yttrium aluminum garnet and a manufacturing method, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as difficulty in ensuring the performance stability and consistency of final products, deficiencies, and difficulty in process control, so as to avoid pollution problems, The effect of reduced damage and high luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

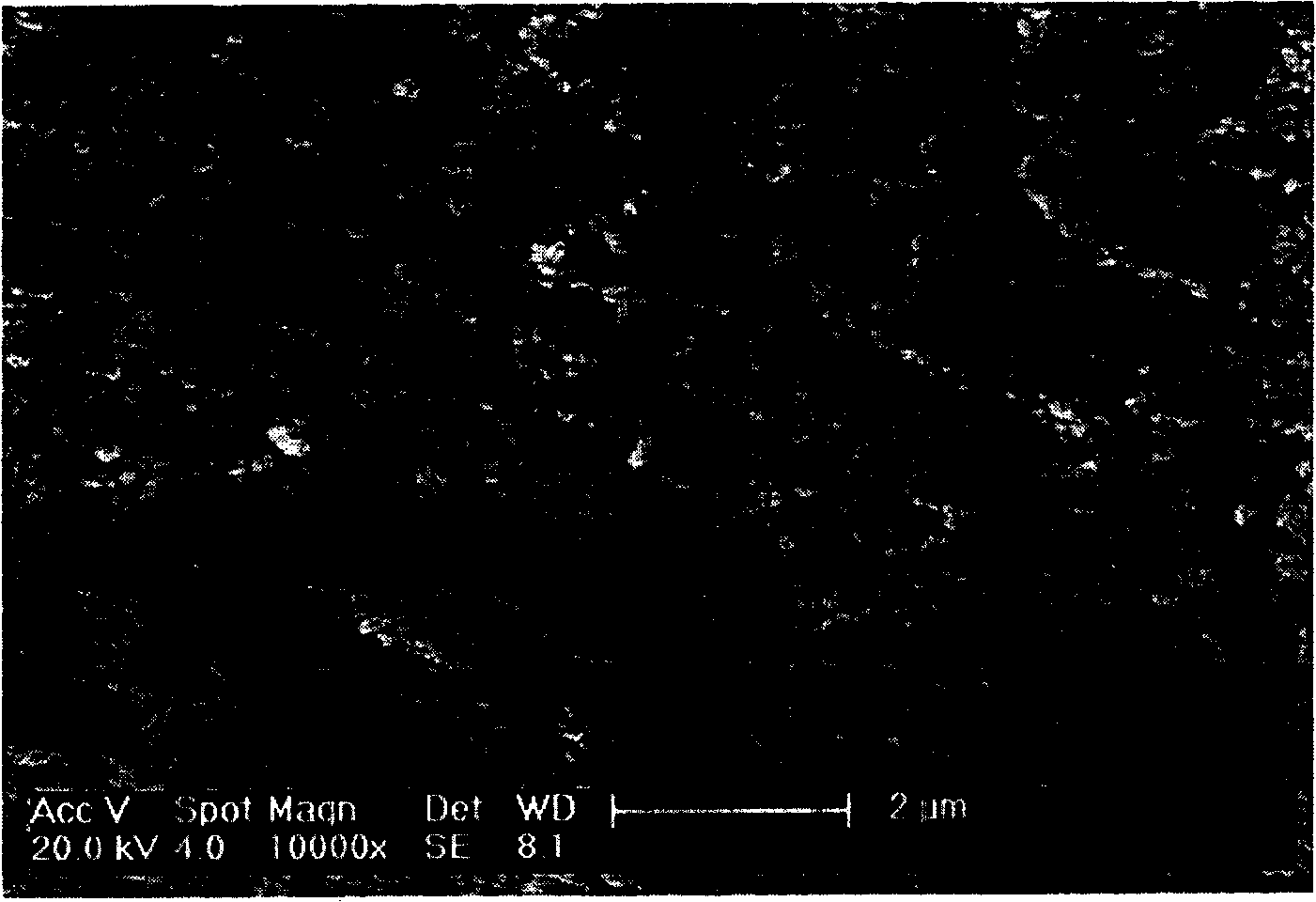

Image

Examples

Embodiment 1

[0016] (1) According to the stoichiometric ratio of the fluorescent powder, weigh the corresponding weight of ultrafine alumina powder, yttrium nitrate, cerium nitrate and gadolinium nitrate to prepare Al with a total concentration of 0.25, 0.73, 0.12, 0.28, 0.37 or 4.5M 2 o 3 suspension.

[0017] (2) Choose NaOH, NH 3 ·H 2 O and NH 4 HCO 3 At least one of them is formulated into a solution with a total concentration of 0.03, 0.05, 0.08, 1.25, 1.59 or 1.9M as a precipitating agent.

[0018] (3) Control the temperature of the prepared precipitation mother liquor within the range of 15, 25, 30, 42, 55 or 65°C, stir the suspension at a speed of 50, 90, 150, 260, 330 or 460rpm, and simultaneously mix the precipitant solution by 34 , 80, 240, 365, 470 or 500mL / min flow rate into the Al 2 o 3 In the suspension, when the pH value of the mother liquor reaches 6.8-11, stop the feeding process, and continue to keep warm and stir for 30, 60, 120, 180 or 240 minutes.

[0019] (4) ...

Embodiment 2

[0024] (1) Weigh Al 2 o 3 25.5g, Ce(NO 3 ) 2 ·6H 2 O 5.65g, Y 2 o 3 32.40g, the Y 2 o 3 Dissolve in 50ml of concentrated nitric acid with a concentration of 5M, heat and concentrate at 90°C to obtain white transparent Y(NO 3 ) 3 ·6H 2 O crystals, Al with deionized water 2 o 3 , Ce(NO 3 ) 2 ·6H 2 O and Y (NO 3 ) 3 ·6H 2 O was made into a 0.6M suspension and heated to 25°C. Then weigh NH4 HCO 3 120g is made into a 25% aqueous solution. While stirring the Al at 120rpm 2 o 3 suspension, while adding NH 4 HCO 3 The solution was added to Al at a flow rate of 25mL / min 2 o 3 In the suspension, when the pH value of the suspension reaches 8.2, stop feeding, continue to stir and keep warm for 120 minutes, centrifuge, wash with deionized water, dehydrate with absolute ethanol, and dry at 90°C. Then put it in a high-temperature reducing atmosphere furnace and heat it to 1350°C, keep it warm for 10 hours, pulverize the cooled powder, and sieve it to obtain the mole...

Embodiment 3

[0026] (1) Weigh Al 2 o 3 25.5g, Ce(NO 3 ) 2 ·6H 2 O 4.78g, Y 2 o 3 33.08g, the Y 2 o 3 Dissolve in 50ml of concentrated nitric acid with a concentration of 5M, heat and concentrate at 90°C to obtain white transparent Y(NO 3 ) 3 ·6H 2 O crystals, Al with deionized water 2 o 3 , Ce(NO 3 ) 2 ·6H 2 O and Y (NO 3 ) 3 ·6H 2 O was made into a 0.6M suspension and heated to 25°C. Then weigh 20 g of NaOH to prepare a 10% aqueous solution. While stirring the Al at 120rpm 2 o 3 suspension, while adding NH 4 HCO 3 The solution was added to Al at a flow rate of 16mL / min 2 o 3 In the suspension, when the pH value of the suspension reaches 8.5, stop feeding, continue to stir and keep warm for 120 minutes, centrifuge, wash with deionized water, dehydrate with absolute ethanol, and dry at 90°C. Then put it in a high-temperature reducing atmosphere furnace and heat it to 1400°C, keep it warm for 6 hours, pulverize the cooled powder, and sieve it to obtain Y 2.89 Al 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com