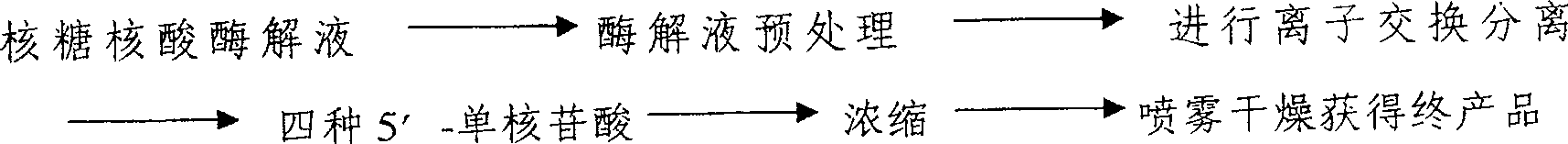

Method for preparing nucleotide from enzymolysis liquid of ribonuclease

A ribonucleic acid enzymatic hydrolysis solution and strong acid technology, which is applied in the preparation of sugar derivatives, chemical instruments and methods, sugar derivatives, etc., can solve the problems of production methods that cannot meet the needs, high requirements for equipment and environment, and long elution and separation time, etc. problem, to achieve good clarity, shorten the separation and purification time, and facilitate separation and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The ribonucleic acid hydrolysate was passed through two ultrafiltration membrane equipment to remove solid particles and proteins, and the filtration recovery rate was greater than 90%. The MWCO of the two ultrafiltration membranes were 20,0000 and 6,000 Daltons respectively; after ultrafiltration, the filtrate protein was 0.005mg / ml; adjust the pH of the ultrafiltrate to 1.5 with 6N HCl, and separate it on an ion exchange column, which contains 2065g of nucleotides, 5′-AMP (2065×28%) grams; 5′-GMP (2065×26%) grams; 5'-CMP (2065 x 20%) g; 5'-UMP (2065 x 26%) g.

[0040] The ultrafiltrate containing the four mononucleotides was separated into UMP, GMP and CMP mixed solution, AMP three part.

[0041] Cation exchange resin loading column: pH 1.5, sample loading flow rate 1.5m / h, nucleotide loading amount is 6.0% of the total exchange capacity of cation resin; product loss rate in column separation: within 5%.

[0042] Contrast value and concentration for identification:...

Embodiment 2

[0051] The ribonucleic acid hydrolysate containing 2080 grams of nucleotides was subjected to plate and frame pressure filtration-ultrafiltration membrane equipment to remove solid particles and proteins, and the filtration recovery rate was greater than 95%. The ultrafiltration membrane MWCO was 10,000 Daltons; the filtrate after ultrafiltration Protein 0.02mg / ml; adjust the pH of the ultrafiltrate to 2.0 with 12NHCl, and separate it on an ion exchange column, which contains 2080g of nucleotides, 5′-AMP (2080×26.8%) grams; 5′-GMP (2080×28.2%) ) grams; 5′-CMP (2080×20.1%) grams; 5′-UMP (2080×24.6%) grams.

[0052] The nucleotide loading of the 732 cation exchange resin column was 6.0% of the total exchange capacity of the resin, and the separation linear velocity was 1.75 m / h. The loading volume of other concentration columns is: Dowex-1 negative column AMP loading volume is 45%; GMP+CMP separation column loading volume is 12%; CMP25%; UMP18%, using acid salt eluent (0.5% sal...

Embodiment 3

[0056] The ribonucleic acid enzymatic hydrolysate was passed through two ultrafiltration membrane equipment to remove solid particles and proteins, and the filtration recovery rate was 95%. The MWCO of the two ultrafiltration membranes were 100,000 and 10,000 Daltons respectively; after ultrafiltration, the filtrate protein was 0.01mg / ml; adjust the pH of the ultrafiltrate to 1.0 with 10NHCl, and separate it on a JK008 cation exchange column, which contains 2770g of nucleotides, 5′-AMP (2770×25%) grams; 5′-GMP (2770×28%) grams; 5'-CMP (2770 x 18%) g; 5'-UMP (2770 x 25%) g.

[0057] The nucleotide loading of the 001×8 ion exchange resin column was 8.0% of the total exchange capacity of the resin, and the separation linear velocity was 1.0 m / h. The loading volume of other concentration columns is: Amberlite IRA-400 negative column AMP loading volume is 40%; GMP+CMP separation column loading volume is 15%; CMP30%; UMP20%, using acid salt eluent (1 % salt, pH 2) for separation a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com