Method of synchronously cleansing air pollutant by smoke of plasma discharge caused by spreading light

A plasma and streamer discharge technology, which is applied in the field of simultaneous purification of various pollutants in flue gas and flue gas purification, can solve the problems of large flue gas purification systems, high equipment investment and operating costs, key technologies and materials, etc. Achieve the effect of small footprint, saving land, low investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: streamer discharge plasma soot purification

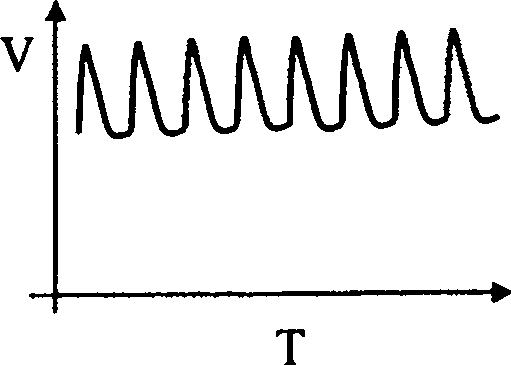

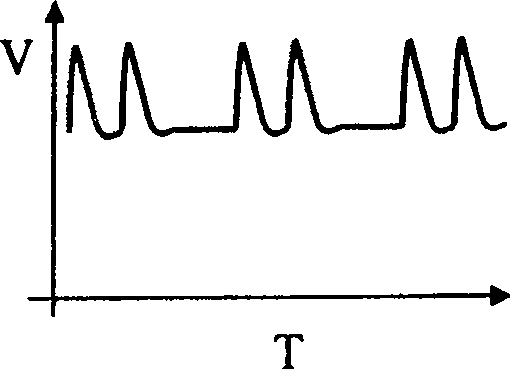

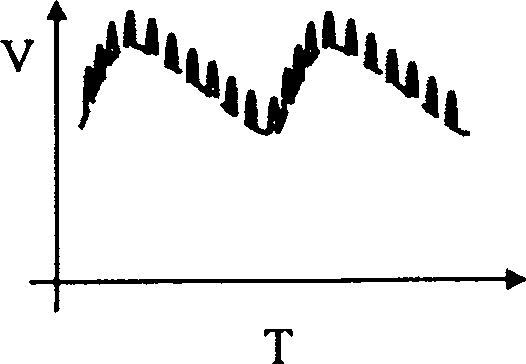

[0039] The high-frequency pulse power supply converts the input 380V AC signal into a 10kHz-15kHz high-frequency pulse through the AC-DC-AC conversion method, and uses a thyristor rectifier to realize DC / AC conversion. The inverter composed of field effect semiconductor power modules The inverter realizes the DC / AC inversion process, and supplies power to the reactor through the pulse transformer. figure 1 DC superimposed positive polarity pulse continuous power supply, DC base voltage is 50kV; pulse voltage is 50kV, pulse frequency is 6kHz. Compared with the previous narrow pulse power supply, the biggest difference is that the DC base voltage is higher than the DC corona inception voltage, and there is no longer any limitation on the rise time and pulse width of the pulse output. The change rate of the pulse voltage is greater than 200V / μs, which can produce better streamer discharge plasma. This power supp...

Embodiment 2

[0041] Example 2: Streamer discharge plasma flue gas conditioning

[0042] When burning low-sulfur coal, the specific resistance of soot is high (>10 10 Ω.cm), so that the traditional electrostatic precipitator often occurs back corona, and the dust removal efficiency is low. At present, the technologies to solve the dust emission of high specific resistance include bag filter, pulse or intermittent power supply electric precipitator and flue gas conditioning. The commonly used conditioning agent is SO 3 and NH 3 .

[0043] In fact, industrial electrostatic precipitators usually use multiple electric fields (3-5), and the streamer discharge plasma generation technology disclosed in this patent can be used to change traditional electric precipitators into plasma reactors or composite electric precipitators, such as Figure 10 As shown, the power supply of the first electric field of the traditional electrostatic precipitator is changed to a positive polarity streamer dischar...

Embodiment 3

[0045] Example 3: streamer discharge plasma electrostatic precipitator-bag dust removal flue gas purification

[0046] Compared with electrostatic precipitator, the combination of electrostatic precipitator and bag filter has higher dust removal efficiency. Compared with bag filter, the cost of electrostatic precipitator and bag filter combination is lower, so the industrial application prospect is better. Dust removal-bag type dust removal combination only plays the role of dust removal, and fails to effectively control harmful gases. Figure 11 Disclosed is a streamer discharge plasma type electric dust removal-bag dust removal method. The flue gas first enters the traditional electrostatic precipitator 14 of the first section to remove larger dust particles, and the flue gas discharged from the electrostatic precipitator 14 enters the streamer discharge plasma reactor 8 of the second section, where the electrostatic precipitator 14 and streamer Humidification facilities ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com