Preparation and application of MoS < 2 >-C double-layer hollow sphere with high specific surface area

A high specific surface area, double-layer hollow technology, applied in the direction of microsphere preparation, carbon preparation/purification, microcapsule preparation, etc., can solve single problems, achieve uniform shape, simultaneous photocatalytic degradation and capacitive adsorption desalination, The effect of improving performance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

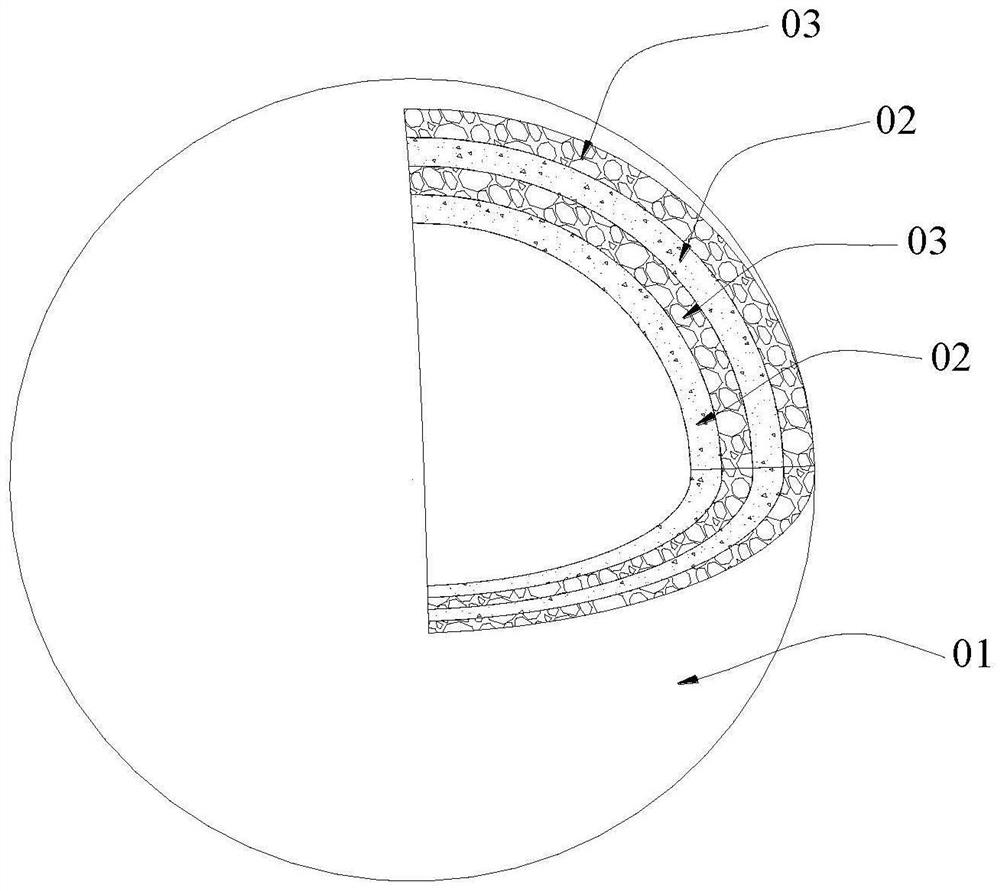

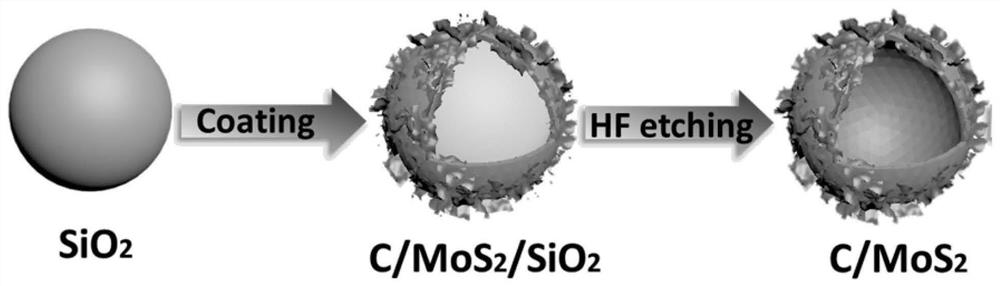

[0048] 1. MoS with high specific surface area 2 Preparation of @C Bilayer Hollow Spheres

[0049] (1) SiO 2 Preparation of Nanosphere Templates

[0050] Deionized water (10 mL), ethanol (70 mL), tetraethyl orthosilicate (TEOS) (3.5 mL) and NH were added to the beaker sequentially 3 ·H 2 O (27wt%) (3mL), vigorously stirred at room temperature for 25min, after a period of stirring, the solution will gradually change from transparent to milky white, and SiO 2 nanospheres;

[0051] (2) MoS 2 @C synthesis of hollow spheres

[0052] With the SiO prepared in step (1) 2 The nanospheres are used as templates. After the solution in step (1) is evenly stirred, 0.4 g of resorcinol and 0.4 g of ammonium tetrathiomolybdate are successively added, and after continuous stirring for 2 h, 0.8 mL of formaldehyde solution (37w%) is added dropwise. ), continue to stir until the solution becomes a uniform suspension, then transfer to a 100ml polytetrafluoroethylene reactor for hydrothermal ...

Embodiment 2

[0059] 1. MoS with high specific surface area 2 Preparation of @C Bilayer Hollow Spheres

[0060] (1) SiO 2 Preparation of Nanosphere Templates

[0061] Deionized water (10 mL), ethanol (70 mL), tetraethyl orthosilicate (TEOS) (3.5 mL) and NH were added to the beaker sequentially 3 ·H 2 O (27wt%) (3mL), vigorously stirred at room temperature for 25min, after a period of stirring, the solution will gradually change from transparent to milky white, and SiO 2 nanospheres;

[0062] (2) MoS 2 @C synthesis of hollow spheres

[0063] With the SiO prepared in step (1) 2 The nanospheres are used as templates. After the solution in step (1) is evenly stirred, an appropriate amount of resorcinol, 0.6 g of ammonium molybdate and 0.6 g of ascorbic acid are successively added, and the theoretical C content is 5%. After adding 0.8g thiourea, add 0.8mL formaldehyde solution (37w%) dropwise, continue stirring until the solution is a uniform suspension, transfer to a 100ml polytetrafluo...

Embodiment 3

[0070] 1. MoS with high specific surface area 2 Preparation of @C Bilayer Hollow Spheres

[0071] (1) SiO 2 Preparation of Nanosphere Templates

[0072] Deionized water (10 mL), ethanol (70 mL), tetraethyl orthosilicate (TEOS) (3.5 mL) and NH were added to the beaker sequentially 3 ·H 2 O (27wt%) (3mL), vigorously stirred at room temperature for 25min, after a period of stirring, the solution will gradually change from transparent to milky white, and SiO 2 Nanospheres.

[0073] (2) MoS 2 @C synthesis of hollow spheres

[0074] With the SiO prepared in step (1) 2 The nanosphere is used as a template. After the solution in step (1) is evenly stirred, an appropriate amount of resorcinol, 0.8 g of ammonium molybdate and 0.5 g of hydroxylamine hydrochloride are successively added, and the theoretical C content is 10%. After continuous stirring for 2 hours, After adding 1.2g of sodium sulfide, add 0.8mL formaldehyde solution (37w%) dropwise, continue to stir until the soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com