Method and apparatus for combined removing sulfur-dioxide and nitrogen oxide by mixed solution

A mixed solution and sulfur dioxide technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as high energy loss, corrosion in the furnace, etc., achieve high overall efficiency, low operating costs, and no secondary pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

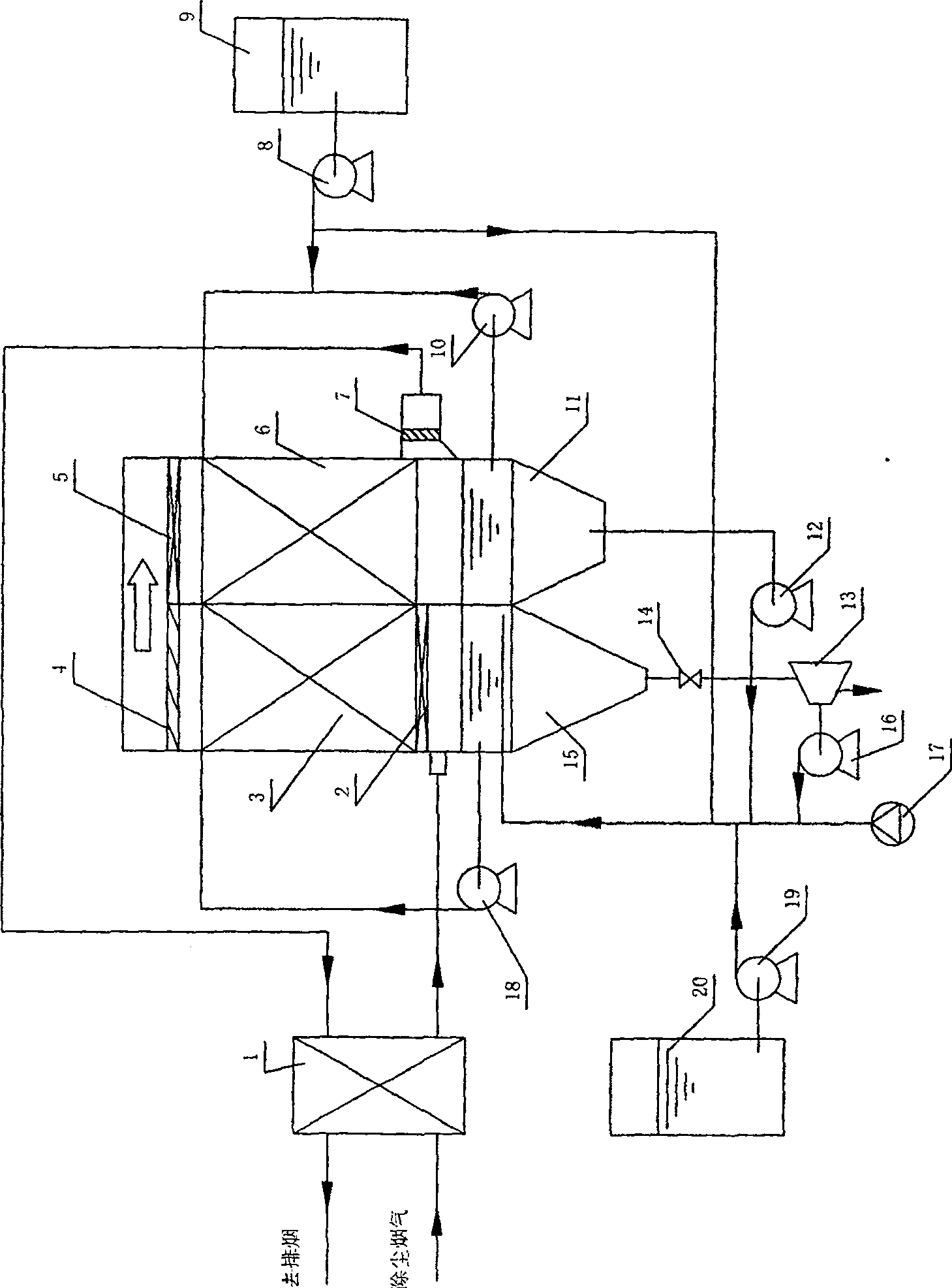

[0059] refer to figure 1 To describe in detail the embodiment of the urea / ammonia / additive solution combined removal method for sulfur dioxide and nitrogen oxides in flue gas of the present invention.

[0060] Contains sulfur dioxide 600mg / Nm 3 ~6000mg / Nm 3 and nitrogen oxides 400mg / Nm 3 ~3000mg / Nm 3 After the flue gas is dedusted at about 160°C, it enters the heat exchanger 1 through the pipeline and cools down to 100-110°C, and then enters the main body of the primary reactor; the flue gas first passes through the primary gas distributor 2 and enters the primary absorption reactor 3 and Blended with additives such as triethanolamine or ethylenediamine, the additives are added to the urea / ammonia mixed solution with a mass percentage of 0.005% to 0.025% of the urea / ammonia solution. The concentration of the primary ammonia solution is 2% to 10% and the concentration of the urea solution is 2%. ~6% are in gas-liquid mixed contact, most of the SO 2 Absorbed and removed her...

Embodiment 2

[0061] Embodiment 2: The method for combined removal of sulfur dioxide and nitrogen oxides by the mixed solution disclosed by the present invention is as follows:

[0062] Step 1: Cool the flue gas after dedusting to 100°C to 110°C, then make the flue gas contact with the urea / ammonia water mixed solution mixed with additives, and the liquid-gas ratio of the mixed solution to the flue gas is 1.5 ~4L / m 3 , the concentration of ammonia water in the mixed solution is 2% to 10%, the concentration of urea in the mixed solution is 2% to 6%, the mixed solution is used as a primary absorption solution and its pH value is maintained at 5 to 7, and the temperature is controlled at 30℃~60℃, SO in flue gas 2 and NO x Absorbed, compressed air is blown into the solution after contacting with flue gas and reacting to oxidize ammonium sulfite to ammonium sulfate, and the addition amount of the above additives is 0.005% to 0.025% by mass of the urea / ammonia solution;

[0063] The second ste...

Embodiment 3

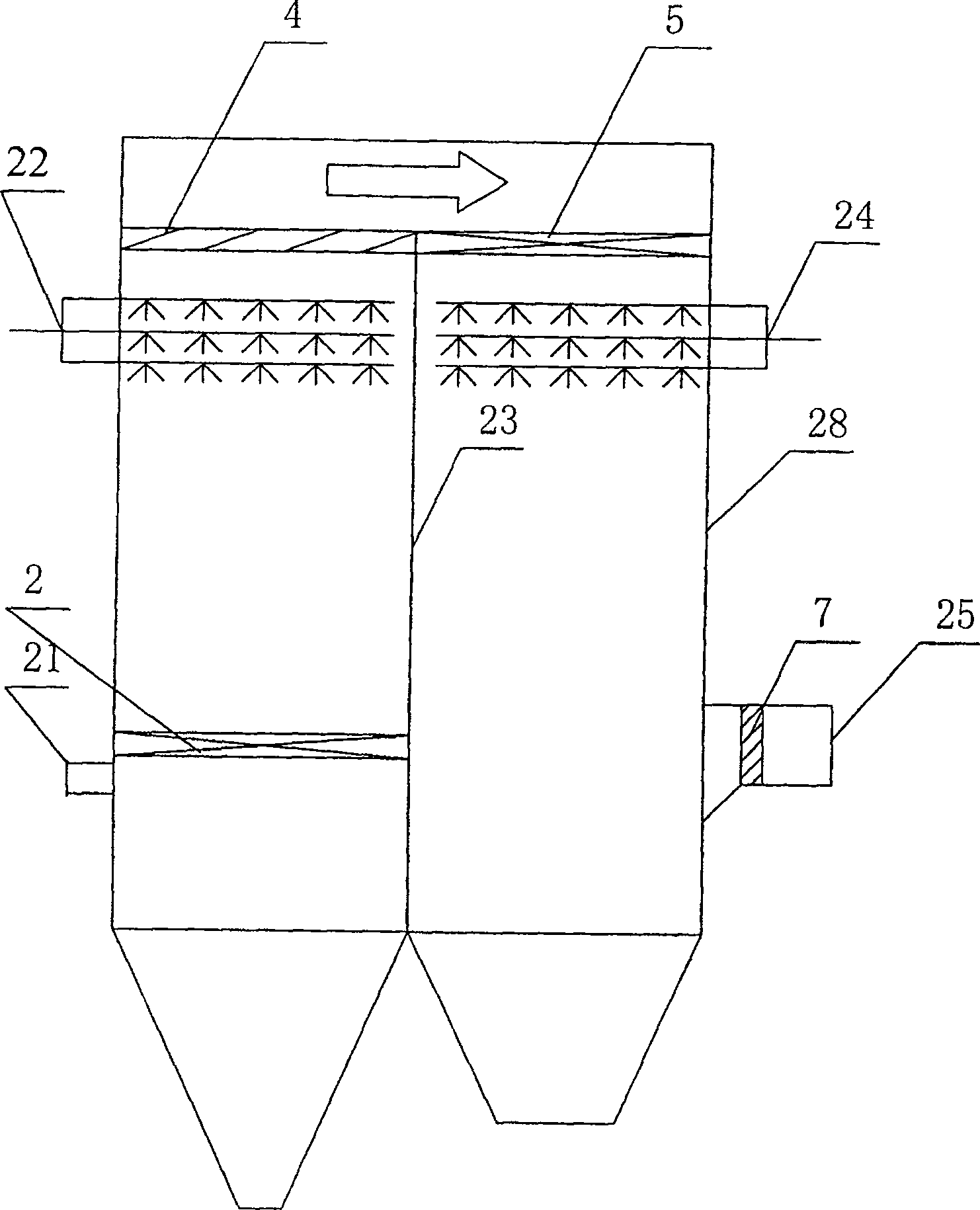

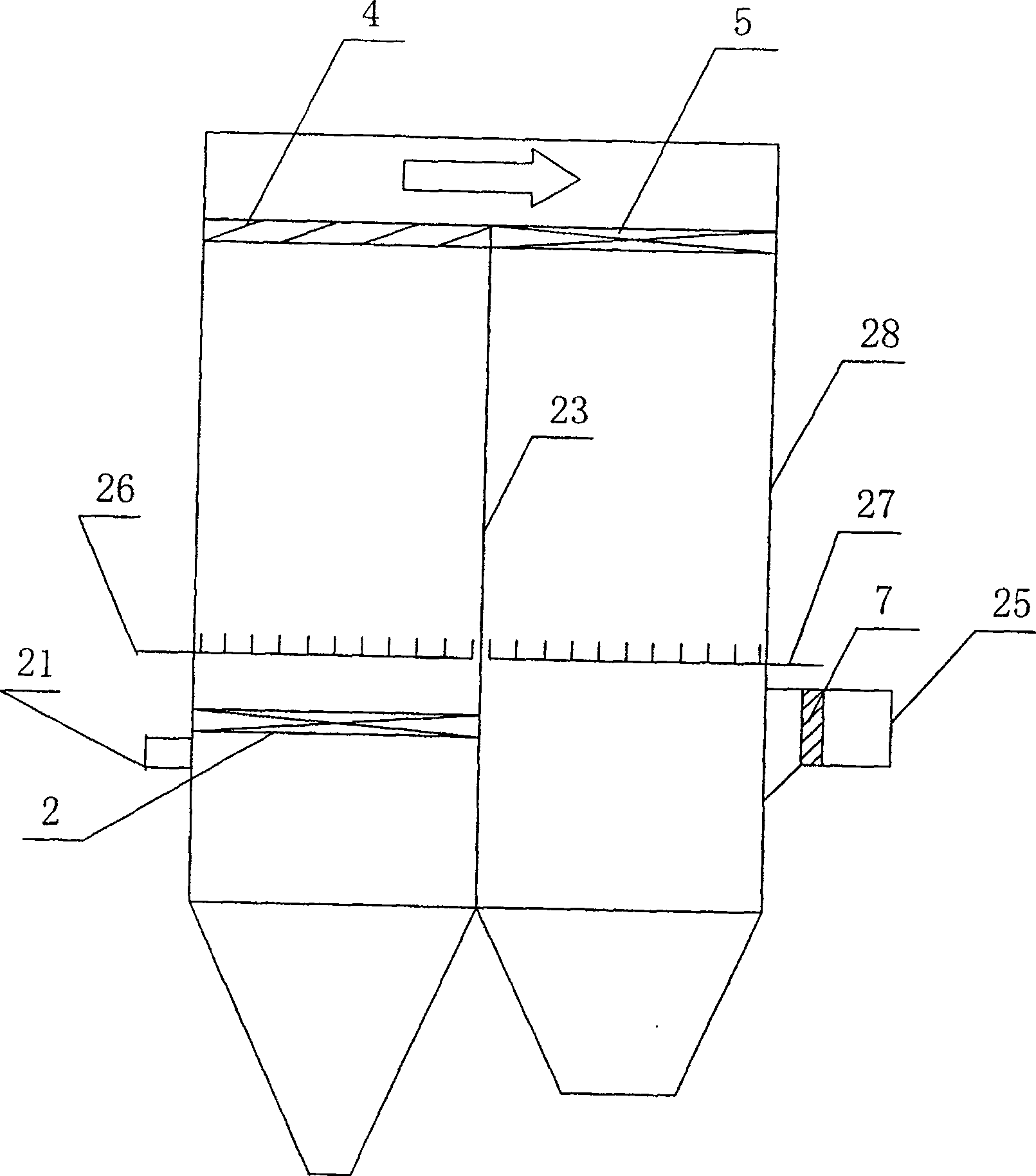

[0066]Embodiment 3: A kind of device that is used to implement described mixed solution joint removal sulfur dioxide and nitrogen oxide method is to be made up of heat exchanger 1, primary gas distributor 2, primary absorption reactor 3, primary mist eliminator 4. Secondary gas distributor 5, Secondary absorption reactor 6, Secondary demister 7, Secondary circulation pump 10, Secondary liquid collection tank 11, Pump 12, Centrifuge 13, Primary liquid collection tank 15, Separation liquid pump 16, air compressor 17, primary circulation pump 18, primary gas distributor 2 is arranged in primary absorption reactor 3, secondary gas distributor 5 is arranged in secondary absorption reactor 6, heat The flue gas outlet of the exchanger 1 is connected to the flue gas inlet 21 of the primary absorption reactor, the flue gas outlet of the primary absorption reactor 3 is connected to the flue gas inlet of the secondary absorption reactor 6, and the primary mist eliminator 4 is located bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com