Method for producing high-temperature alpha-amylase by thermococcaceae aeropyrum pernix and product thereof

A technology of thermophilic archaea and cocci, applied in the direction of biochemical equipment and methods, enzymes, bacteria, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

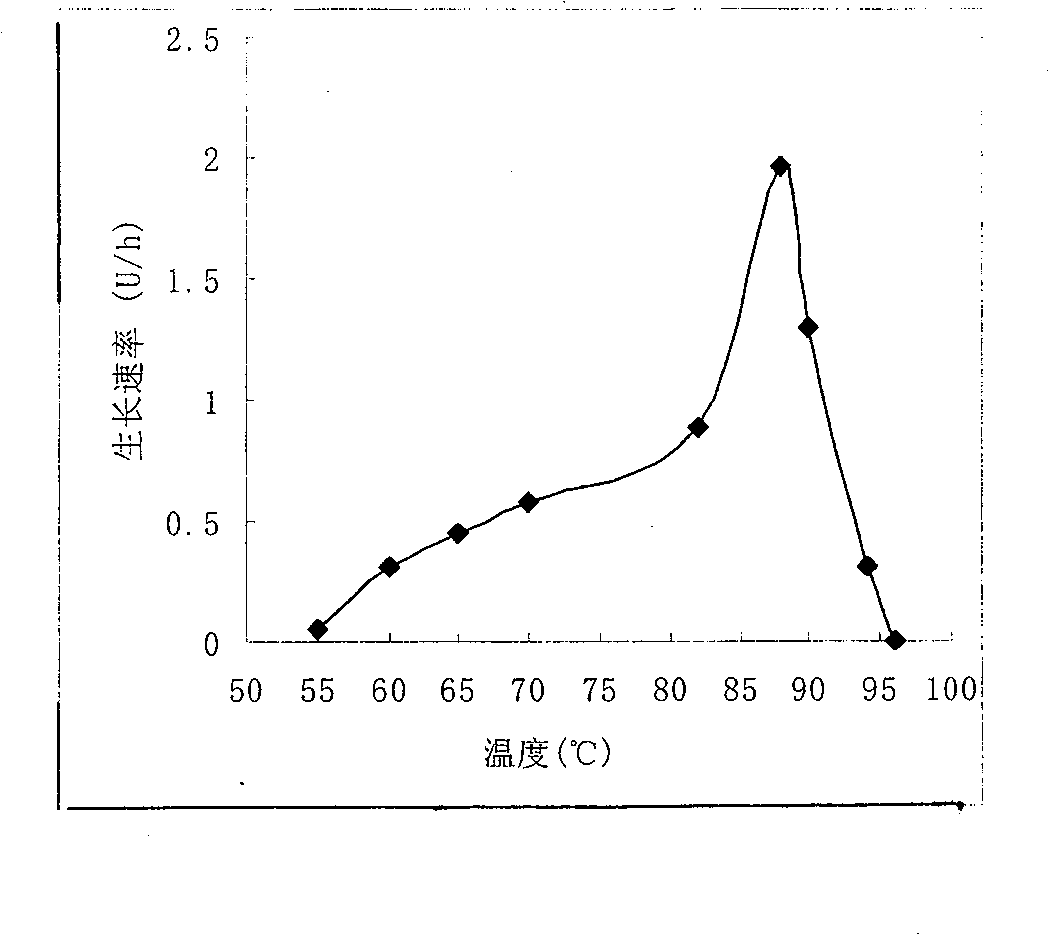

[0063] Example 1. A Thermococcus siculi HJ21 (Thermococcus siculi HJ21) CCTCC NO: M 207010. The strain has the following characteristics: the strain is a strictly anaerobic coccus with a diameter of 0.5-1um; the growth temperature range of the strain is 55-94°C, and its optimum growth temperature is 88°C; the optimum growth pH range is 6.5-7.0, low The strain does not grow at 4.5 or higher than 9.0; the growth NaCl concentration range is 1-5%, 2% is the most suitable NaCl concentration, no NaCl and higher than 5% do not grow; the strain grows well in protein-rich substrates; starch, Maltose, glucose, sucrose, cellobiose, lactose, glycogen, gelatin promote the growth of the strain.

Embodiment 2

[0064] Example 2. Utilize the method for thermostable acid α-amylase produced by Thermococcus thermophilic archaea HJ21 CCTCC NO: M207010 described in Example 1, the steps are as follows,

[0065] (1) Inoculate the strain in YPS medium with a pH of 6.5, and cultivate it at 88°C for 8-9 hours; take out the fermentation broth and cool it to room temperature, filter and remove sulfur particles with a vacuum circulation pump, and then centrifuge at 11000rpm / min for 20min. supernatant to obtain crude enzyme liquid;

[0066](2) Add ammonium sulfate powder to the crude enzyme solution to 70% saturation, stir while adding, continue to stir for 15 minutes after the addition, and then place it in a 4°C incubator for 12 hours; then 11000r / min, 20min Collect the precipitate by centrifugation, add an appropriate amount of 50mM Tris-HCl buffer solution with a pH of 7.5 to dissolve, put the salted out solution in a dialysis bag, place it at 4°C, and dialyze it with a 50mM Tris-HCl buffer so...

Embodiment 3

[0067] Example 3. The high temperature-resistant acid alpha-amylase produced by the method described in embodiment 2, described high temperature resistant acid alpha-amylase has the following characteristics:

[0068] (1) The optimum action temperature of the enzyme is 95°C, and the enzyme has good thermal stability. The enzyme keeps the enzyme activity unchanged at 90°C for 2 hours, 75% of the enzyme activity at 100°C for 1 hour, and 110°C for 2 hours. 40% enzyme activity, is a high temperature resistant α-amylase;

[0069] (2) The optimal pH of the enzyme is 5.0, and the most stable pH of the enzyme is 5.5, which is an acid α-amylase;

[0070] (3)K + 、Sr 2+ , Mg 2+ 、Na + It has a certain promoting effect on the activity of α-amylase; Cu 2+ , Pb 2 + , Hg 2+ , Zn 2+ Strong inhibitory effect on α-amylase;

[0071] (4) IAA, PMSF, SDS have a strong inhibitory effect on the enzyme, EDTA-Na and 2-hydroxyethanol have an inhibitory effect on the enzyme activity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com