Method for improving gallium nitride based transistor material and device performance using indium doping

A gallium nitride-based, transistor-based technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of poor growth repeatability, difficult growth conditions, narrow material growth window, etc. Effects of equipment level, improved electron mobility, and ease of material growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

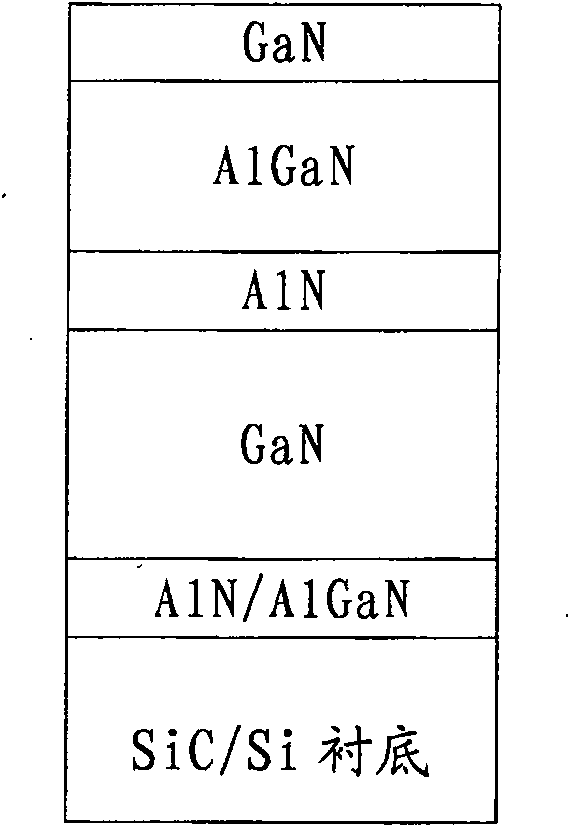

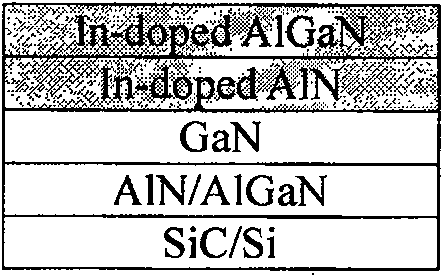

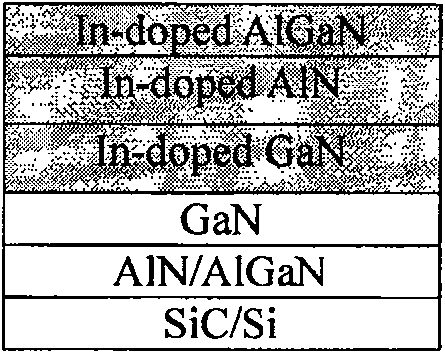

[0018] Figure 2-1 to Figure 2-7 These are several typical structures of indium-doped GaN HEMT materials grown by the technology of the present invention. Its growth equipment uses a metal-organic chemical vapor deposition (MOCVD) epitaxial growth system. The substrate for raw material growth is SiC or Si single crystal substrate. The growth atmosphere is trimethylgallium (TMGa), trimethylaluminum (TMAl ), trimethylindium (TMIn) and ammonia (NH 3 ) respectively as Ga, Al, In and N sources, with hydrogen (H 2 ) is the carrier gas, and the flow rate of trimethylindium (TMIn) is 0-10umol / min during the growth process. Below is Figure 2-1 to Figure 2-7 Growth steps and structural conditions of each structure shown:

[0019] diagram 2-1 To grow a layer of AlN or AlGaN nucleation layer on SiC / Si substrate, then grow GaN buffer layer and channel layer, then grow indi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com