Deoxidation catalyst, preparation method and application thereof

A deoxidation catalyst and catalyst technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of complex components, waste of resources, high chemical activity, etc. Achieve the effects of simple preparation process, good activity stability and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] 2) Preparation of deoxidation catalyst

[0039] A pore-enlarging agent and a binder (liquid peptizer and solid peptizer) are added to the catalyst precursor for kneading, molding, drying and roasting. The solid peptizer used in the present invention comprises Al(OH) 3, pseudo-boehmite or gibbsite, etc., and other precursors of inorganic refractory oxides with bonding effect, the weight consumption accounts for 10%-80% of the dry basis of the entire catalyst, preferably 20%- 50%; the liquid peptizing agent is nitric acid, and its weight consumption accounts for 1%-8% of the dry basis of the entire catalyst, preferably 2%-4%.

[0040] The pore-enlarging agent used in the present invention is an organic pore-enlarging agent, preferably Tianqing powder and / or citric acid, and its weight consumption accounts for 1%-5% of the whole catalyst dry basis, preferably 1.5%-3.5%. The molded catalyst is dried at 80-120°C for 2-10 hours, and calcined at 450-650°C for 2-8 hours. The ...

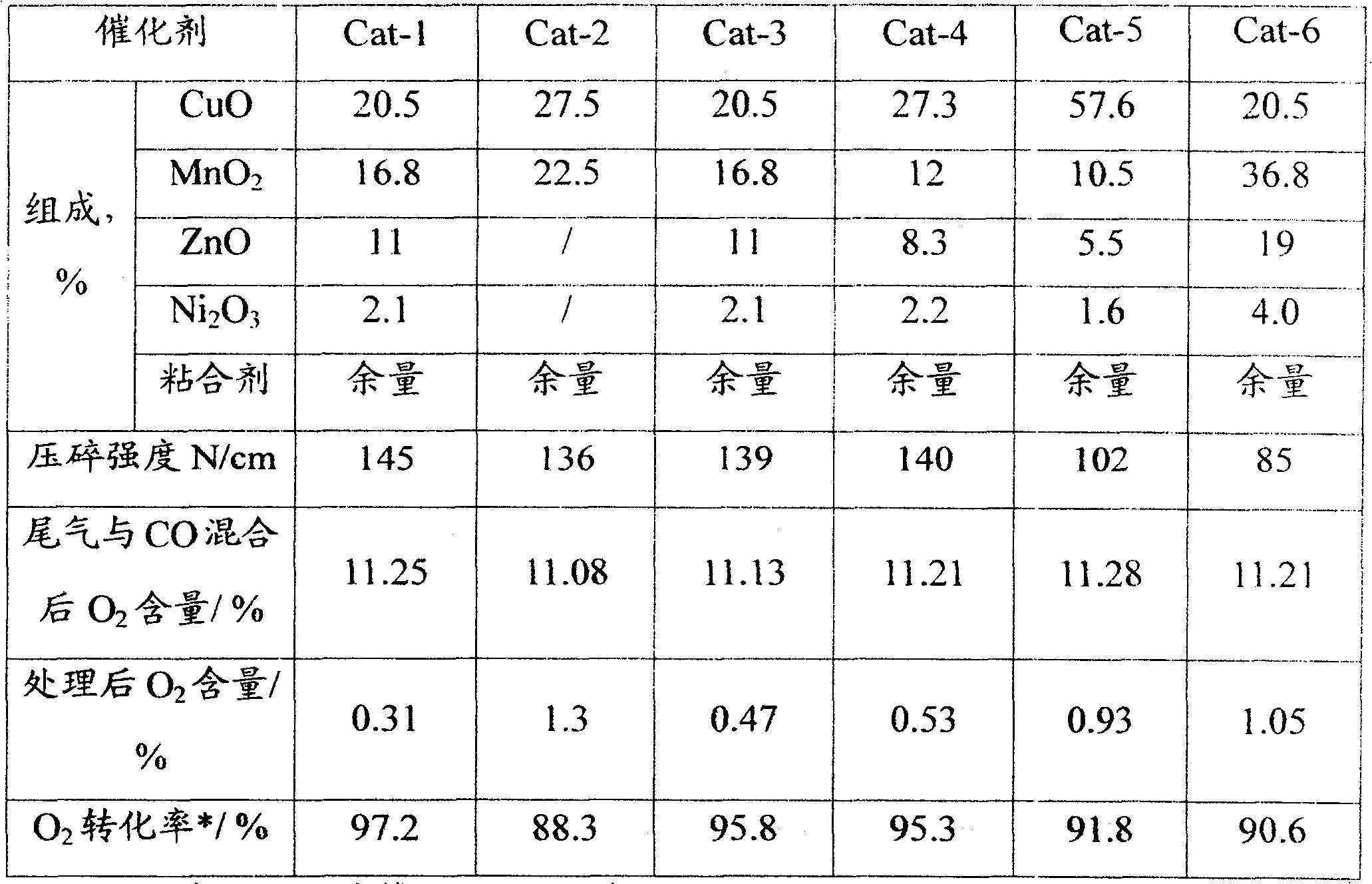

Embodiment 1

[0048] Take the Cu, Zn, Mn, Ni nitrate mixed solution with a total concentration of 0.5mol / L (the molar ratio of Cu:Mn:Zn:Ni is Cu:Mn:Zn:Ni=4:3:2:0.2) In the separatory funnel, take 0.52mol / L of Na 2 CO 3 The solution was placed in another separatory funnel, and the two flowed together to control a certain flow rate and titrated into 15mL of high-speed stirred deionized water, while keeping the pH value of the solution between 7.5-8.5, aging at room temperature for 4h, suction filtration, Washing, drying at 110° C. for 20 hours, and calcining at 550° C. for 4 hours to obtain the catalyst precursor-composite oxide of copper, zinc, manganese and nickel. Add 4g of pore-enlarging agent Tianqing powder, 50g of solid peptizer pseudoboehmite and 7g of liquid peptizer nitric acid into 50g of the catalyst precursor for kneading, molding, drying and roasting. The molded catalyst was calcined at 110°C for 5 hours and 550°C for 4 hours. Its shape was a clover and its size was Φ5×6mm. T...

Embodiment 2

[0050] The preparation method of the deoxidation catalyst is the same as in Example 1, except that the Zn and Ni nitrate mixture is not added. The prepared deoxidation catalyst is designated as Cat-2, and its deoxidation performance and crushing strength are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com