Method for low-temperature synthesis of titanium dioxide nano powder

A technology of titanium dioxide and nano-powder, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of uneven particle size, long production cycle, wide distribution, etc., and achieve short production cycle, The effect of small environmental pollution and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

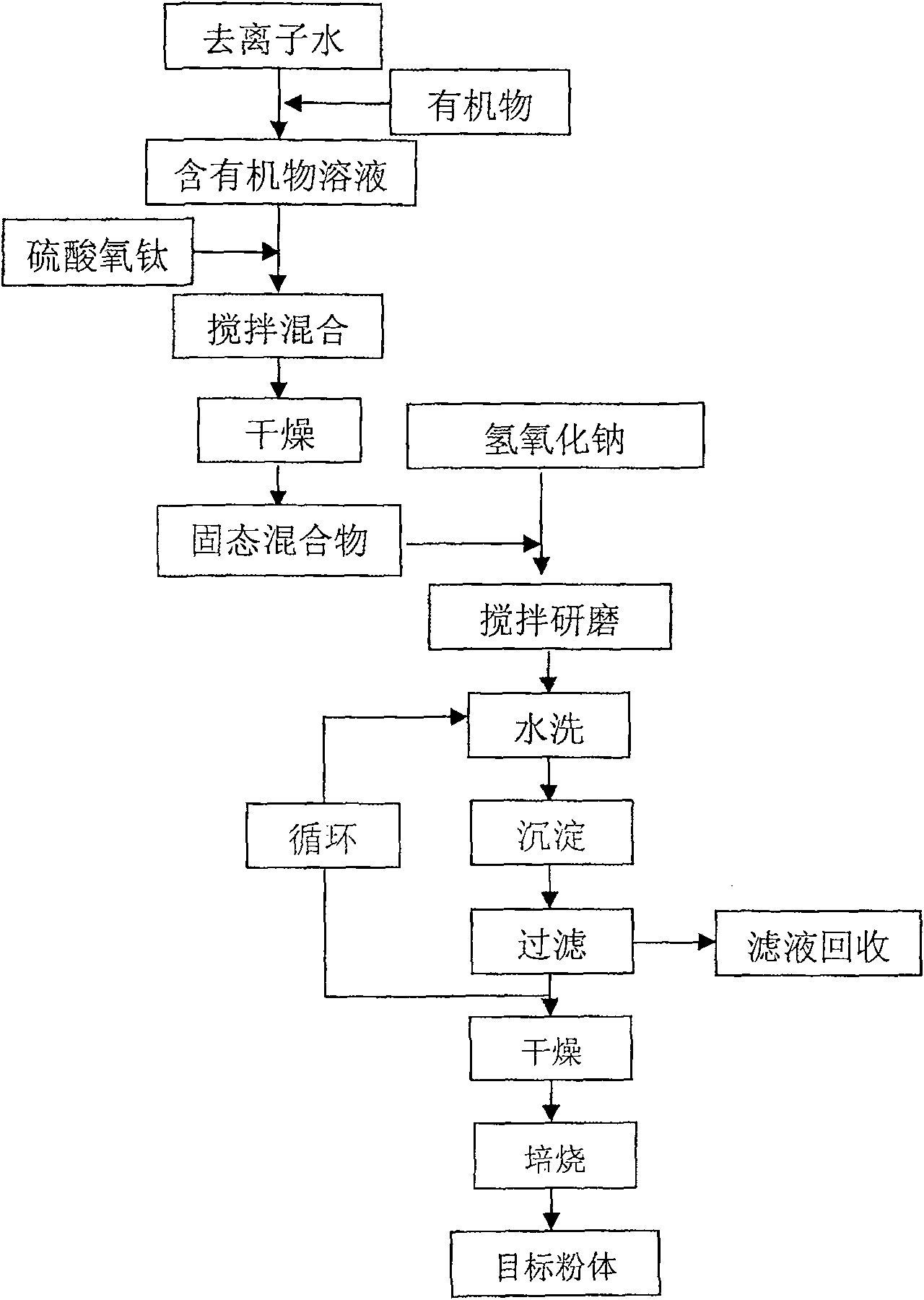

Method used

Image

Examples

Embodiment 1

[0030] Prepare a deionized aqueous solution of ammonium polyacrylate at a molar concentration of 0.001M; weigh 16.8 g of analytically pure sodium hydroxide and 32 g of chemically pure titanyl sulfate at a molar ratio of 2.1:1; dissolve the weighed titanyl sulfate in a concentration of In the ammonium polyacrylate solution of 150ml of 0.001M, stir evenly, dry in drying oven, obtain the solid mixture containing ammonium polyacrylate and titanium; In stirring mill, add sodium hydroxide, then this solid mixture is added to Stirring in the mill, and stirring and grinding for 5 minutes, the rotating speed of the stirring rod is 100rpm, and the white powder is obtained; the reaction product is washed and precipitated for 10 minutes, and then the precipitate is dried in an oven at a temperature of 325K, and the holding time is 3 hours. Obtain nano-titanium dioxide powder; then conduct transmission electron microscope observation; the analysis results show that the transmission electron...

Embodiment 2

[0032] Prepare a deionized aqueous solution of polyethylene glycol 4000 at a molar concentration of 0.1M; weigh 16.8 g of analytically pure sodium hydroxide and 32 g of chemically pure titanyl sulfate at a molar ratio of 2.1:1; dissolve the weighed titanyl sulfate in Concentration is in the polyethylene glycol 4000 solution of 300ml of 0.1M, stir well, dry in drying box, obtain the solid mixture containing polyethylene glycol 4000 and titanium; In stirring mill, add sodium hydroxide, then The solid mixture was gradually added to the stirring mill, stirred and ground for 5 minutes, and the rotating speed of the stirring rod was 600rpm, and a white powder was obtained; the reaction product was washed and precipitated for 360 minutes, and then the precipitate was dried in an oven at a temperature of 385K, and the drying time was 24 hours; place the dried material in a silicon carbide rod furnace, heat it to 473K at a heating rate of 10K / min and keep it warm for 6 hours, then cool ...

Embodiment 3

[0034] Prepare a deionized aqueous solution of Tween 80 at a molar concentration of 0.05M; weigh 180 g of analytically pure sodium hydroxide and 24 g of chemically pure titanyl sulfate at a molar ratio of 30:1; dissolve the weighed titanyl sulfate in a concentration of 0.05 In the Tween 80 solution of 500ml of M, stir evenly, dry in drying box, obtain the solid mixture containing Tween 80 and titanium; In stirring mill, add sodium hydroxide, then add this solid mixture gradually Grinding, stirring and grinding for 30min, the rotating speed of the stirring bar is 600rpm, and the white powder is obtained; the reaction product is washed and precipitated for 60min, and then the precipitate is dried in an oven at a temperature of 355K, and the drying time is 12 hours; In a silicon carbon rod furnace, heat at a heating rate of 5K / min to 773K for 6 hours and then cool with the furnace to obtain a white powder; the obtained white powder does not need to be ground and crushed, and can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com