Material for substituting hydraulic oil in use for isostatic pressing die, and preparation method

A technology of hydraulic oil and isostatic pressure, which is applied in the application field of static pressure molds, can solve the problems of difficulty in metal processing of hydraulic mold structures and heavy workload, high total cost of after-sales service costs, easy leakage of hydraulic systems, etc., to achieve Reduced after-sales service costs, good physical and mechanical properties, difficulty in metal processing and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

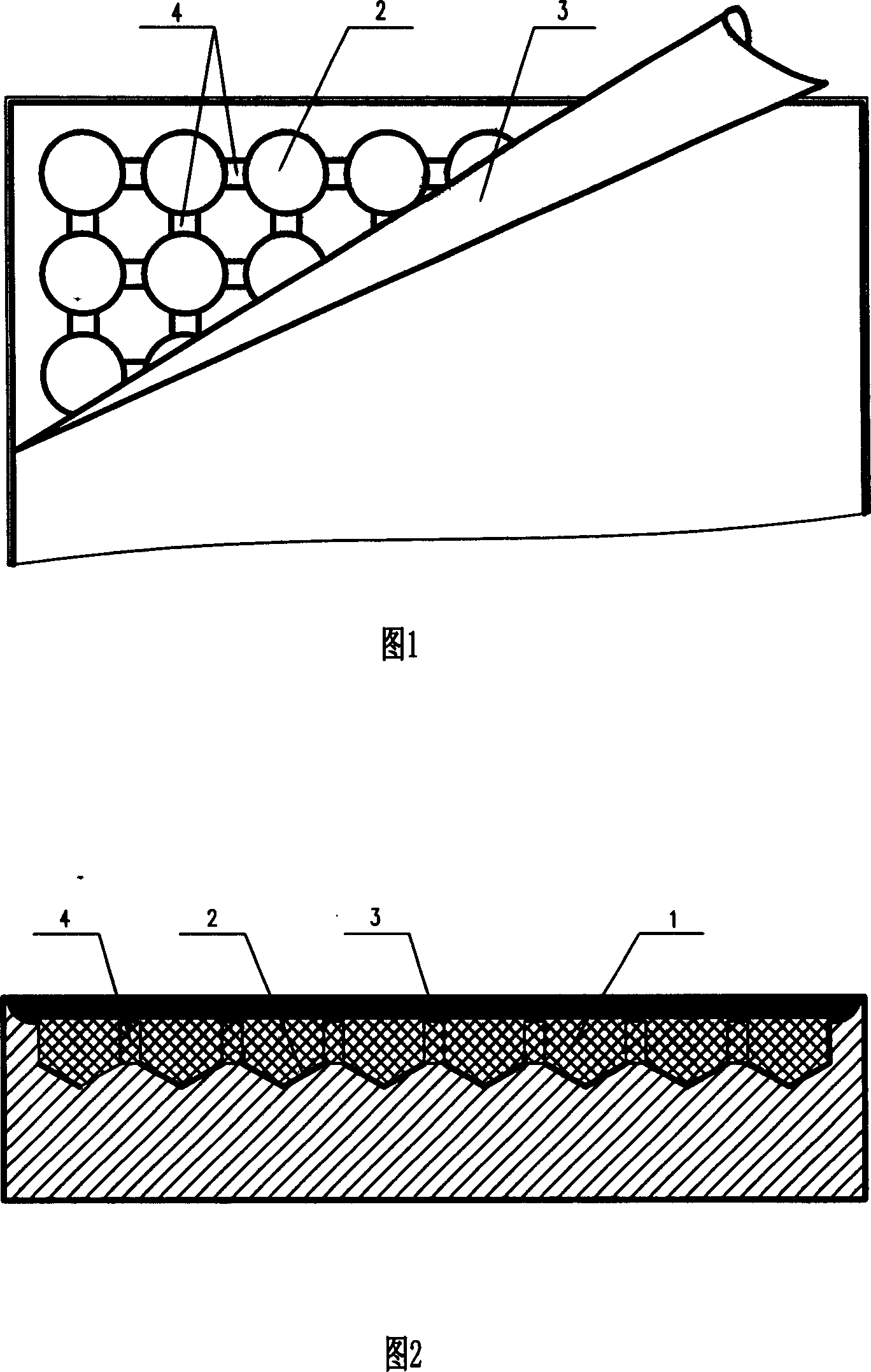

[0020] As shown in Figures 1 and 2, the present invention provides a substitute material for hydraulic oil for isostatic dies, using a quasi-liquid polyurethane elastomer material 1 with a hardness of Shore A0-A20 to replace the hydraulic oil. The quasi-liquid polyurethane elastic The body material is composed of oligomer polyol A containing hydroxyl group, organic substance B containing isocyanate group, plasticizer C, the equivalent ratio of components A and B is 0.6-1.5, and component A is polyoxypropylene polyol , polymer grafted polyether polyol, polyethylene oxide polyol, adipate polyester diol, aromatic polyester diol, dimer polyester diol, polycaprolactone polyol, polypropylene One or more of ester polyols, polyolefin polyols, vegetable oil polyols, component B is toluene diisocyanate, diphenylmethane diisocyanate, polymethylene polyphenyl isocyanate, carbodiimide Modified liquefied, dicyclohexylmethane diisocyanate, one or more of the isocyanate semi-prepolymers synth...

Embodiment 2

[0025] A production method of a substitute material for hydraulic oil for an isostatic mold of the present invention is as follows: firstly, sandblasting the processed metal mold substrate, cleaning and degreasing, and then brushing the adhesive, and then pre-painting it Heat to 80°C for later use.

[0026] Then, prepare the quasi-liquid polyurethane elastomer material 1: take 1000 parts of mixed polyether polyols with a hydroxyl value of 60, 220 parts of liquefied MDI modified by carbodiimide, 10 parts of stannous octoate, dimethyl phthalate 300 parts of oxyethyl ester, fully stirred and mixed at a temperature of 40-80°C, defoamed for 10 minutes, poured into the glue-holding space of the aforementioned spare mold, and should be filled, wait until it is semi-solidified, and then pour the surface glue , and then 80 ~ 120 ° C vulcanization molding, and then post-treatment temperature is 85 ~ 90 ° C, the delay is 11 ~ 16h as a parameter for post-treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com