Processing method of three-dimensional implantable microelectrode array

A micro-electrode array, electrode array technology, applied in electrodes, internal electrodes, printed circuit manufacturing, etc., can solve the complex and expensive processing process, the difficulty of promoting and using electrodes, limiting the pace of brain-computer interface and neural prosthesis research, etc. problem, to achieve the effect of low cost, promotion of wide application, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

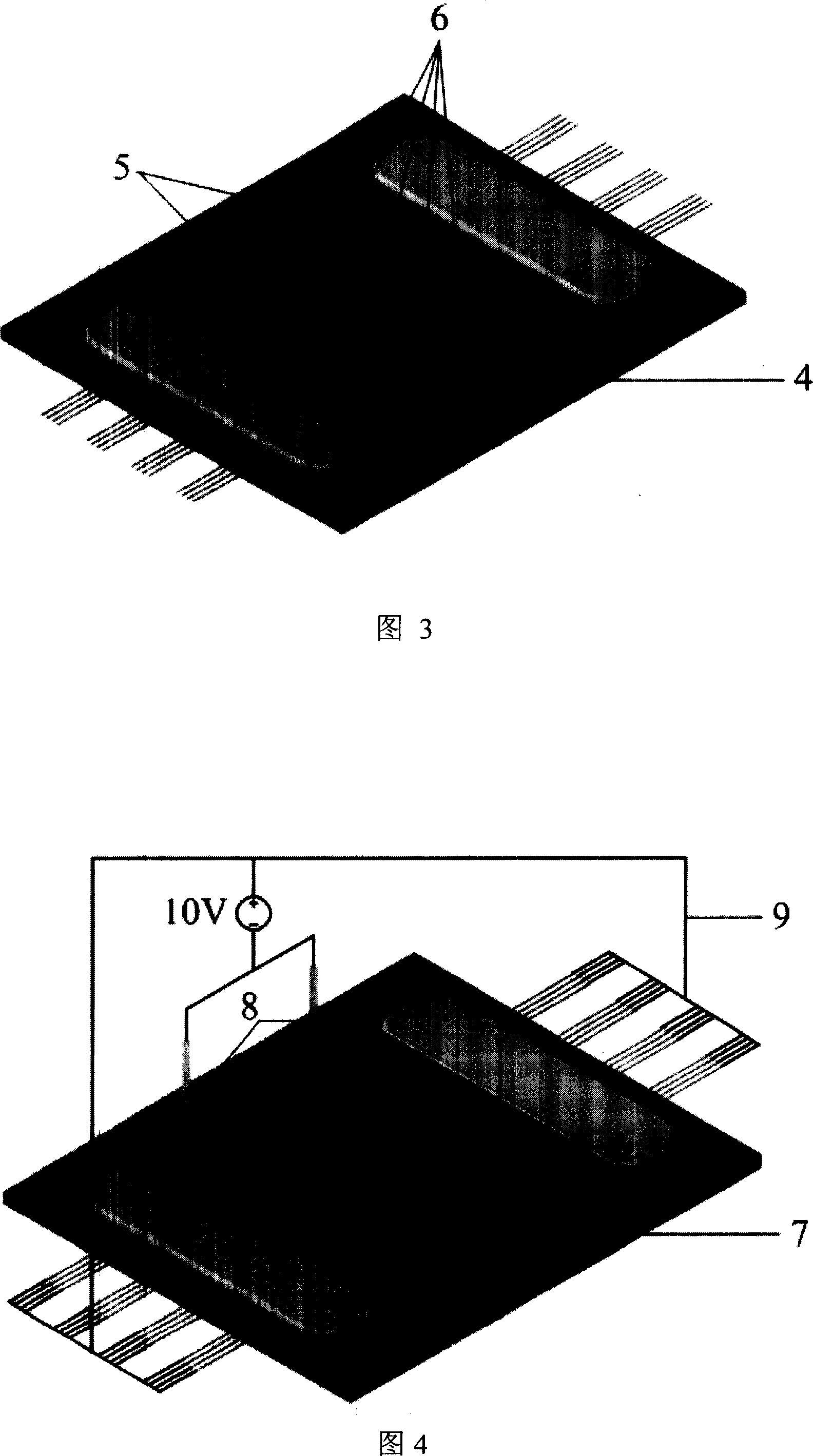

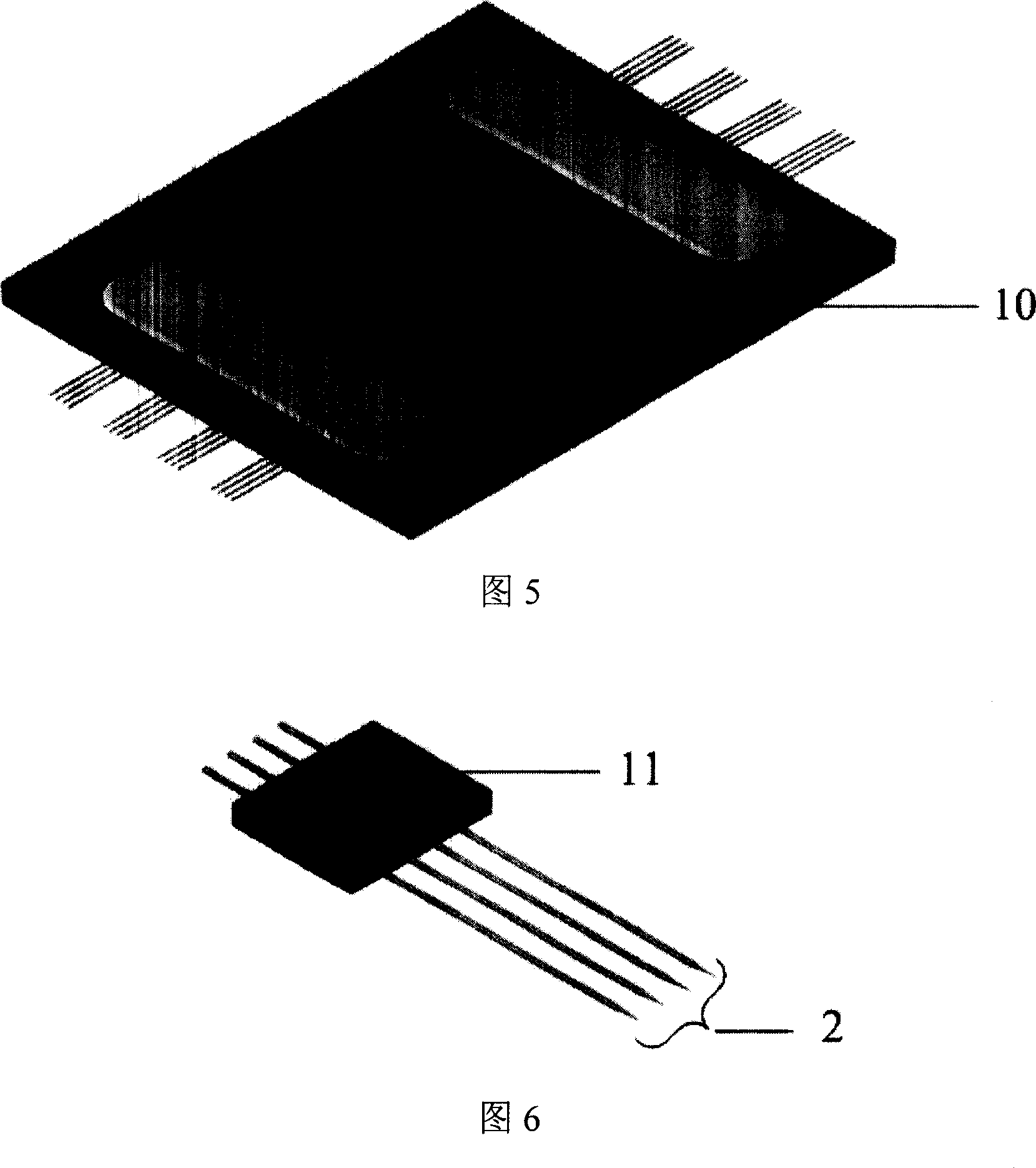

[0017] The manufacturing method of the three-dimensional implanted micro-electrode array of the present invention will be further described below by taking the process of manufacturing a three-dimensional micro-electrode array based on tungsten wire electrode material and glass mold substrate as an example in conjunction with the accompanying drawings.

[0018] 1. First, place the glass substrate in acetone and alcohol for 10 minutes respectively, and clean it with deionized water, and then place it in concentrated H 2 SO 4 Boil in medium for 15 minutes, rinse with deionized water, blow dry with nitrogen gas, and bake in an oven at 200°C for 30 minutes.

[0019] 2. Spin-coat AZ4620 photoresist on the surface of the prepared glass substrate (3000 rpm), and place it in an oven at 80°C for 30 minutes for soft drying, then expose and develop to obtain the desired etching mask layer. graphics, and finally place the developed glass substrate in an oven at 130°C for hard baking for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com