Coordination type boric acid ester coupler containing sulfur element and its preparing process

A technology of borate coupling agent and trialkyl borate, which is applied in the field of coordination type borate coupling agent and its preparation, can solve the problems of poor hydrolysis stability, achieve strong coupling effect, and simple production process , the effect of high hydrolytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation of the coordination type borate coupling agent containing sulfur element is carried out in two steps. The first step is to react an equimolar trialkyl borate with mercaptoethanol to generate a borate compound containing a sulfur-boron coordination bond Removal of the alcohol by-product R during the reaction 1 OH, making the transesterification continue is one of the keys of the present invention. The reaction temperature should be slightly higher than the alcohol by-product R 1 The boiling point of OH is lower than that of the inert solvent xylene.

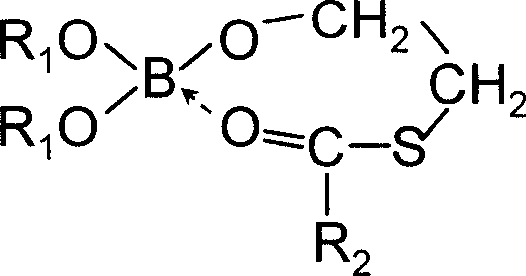

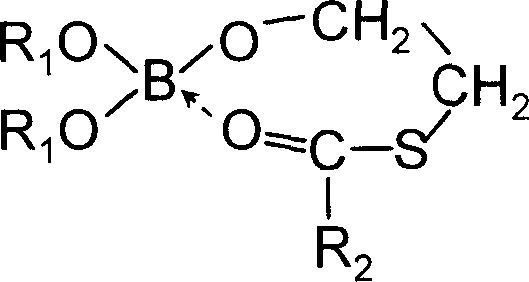

[0022] The sulfur-boron coordination bond is unstable. The second step of the present invention is to react the borate compound containing sulfur-boron coordination bond with fatty acid chloride to generate the borate coupling of sulfur-containing element with thioester bond and (carbonyl) oxygen-boron coordination agent, the reaction principle is

[0023]

[0024] It is one of the keys of the prese...

Embodiment 1

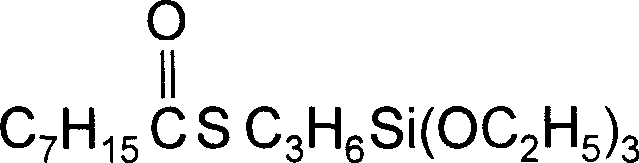

[0027] Using triethyl borate and acetyl chloride as raw materials to prepare the coordination type borate coupling agent containing sulfur elements:

[0028] 1) Weigh 0.1mol (14.58g) of triethyl borate, place it in a round-bottomed three-necked flask, add 277g of xylene, make a solution with a mass concentration of 5%, add 0.1mol (7.80g) of mercaptoethanol, stir, Heating to 80°C, reacting for 7 hours, during which the ethanol by-product was continuously distilled;

[0029] 2) Weigh 0.1mol (8.50g) of pyridine, add it into the solution obtained in step 1), cool to 0°C, stir vigorously and exhaust with nitrogen, add 0.1mol (7.85g) of acetyl chloride dropwise at a speed of 1ml / min, After the dropwise addition, continue to react for 1 h under stirring and exhaust conditions, filter to remove solid salt by-products, and distill under reduced pressure to remove low-boiling fractions to obtain a coordination borate coupling agent containing sulfur elements.

Embodiment 2

[0031] Using tri-n-propyl borate and propionyl chloride as raw materials to prepare the coordination type borate coupling agent containing sulfur elements:

[0032] 1) Weigh 0.1mol (18.78g) of tri-n-propyl borate, place it in a round-bottomed three-neck flask, add 75g of xylene to make a solution with a mass concentration of 20%, add 0.1mol (7.80g) of mercaptoethanol, and stir , heated to 100°C, and reacted for 3 hours, during which the by-product of propanol was continuously distilled;

[0033] 2) Weigh 0.15mol (12.75g) of pyridine, add it to the solution obtained in step 1), cool to 0°C, stir vigorously and exhaust with nitrogen, add 0.1mol (9.25g) propionyl chloride dropwise at a speed of 2ml / min, After the dropwise addition, continue to react for 3 hours under stirring and exhaust conditions, filter to remove solid salt by-products, and distill under reduced pressure to remove low-boiling fractions to obtain a coordination borate coupling agent containing sulfur elements. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com