Process for preparation of polycaprolactone-chitosan network/hydroxyapatite porous compound support frame material

A technology of hydroxyapatite and polycaprolactone, which is applied in the field of biomedical engineering, can solve the problems affecting the ability to form new tissues, easy sealing of holes on the surface of materials, and difficulty in solvent removal, so as to achieve good biological properties and improve mechanical properties. The effect of improving performance and compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

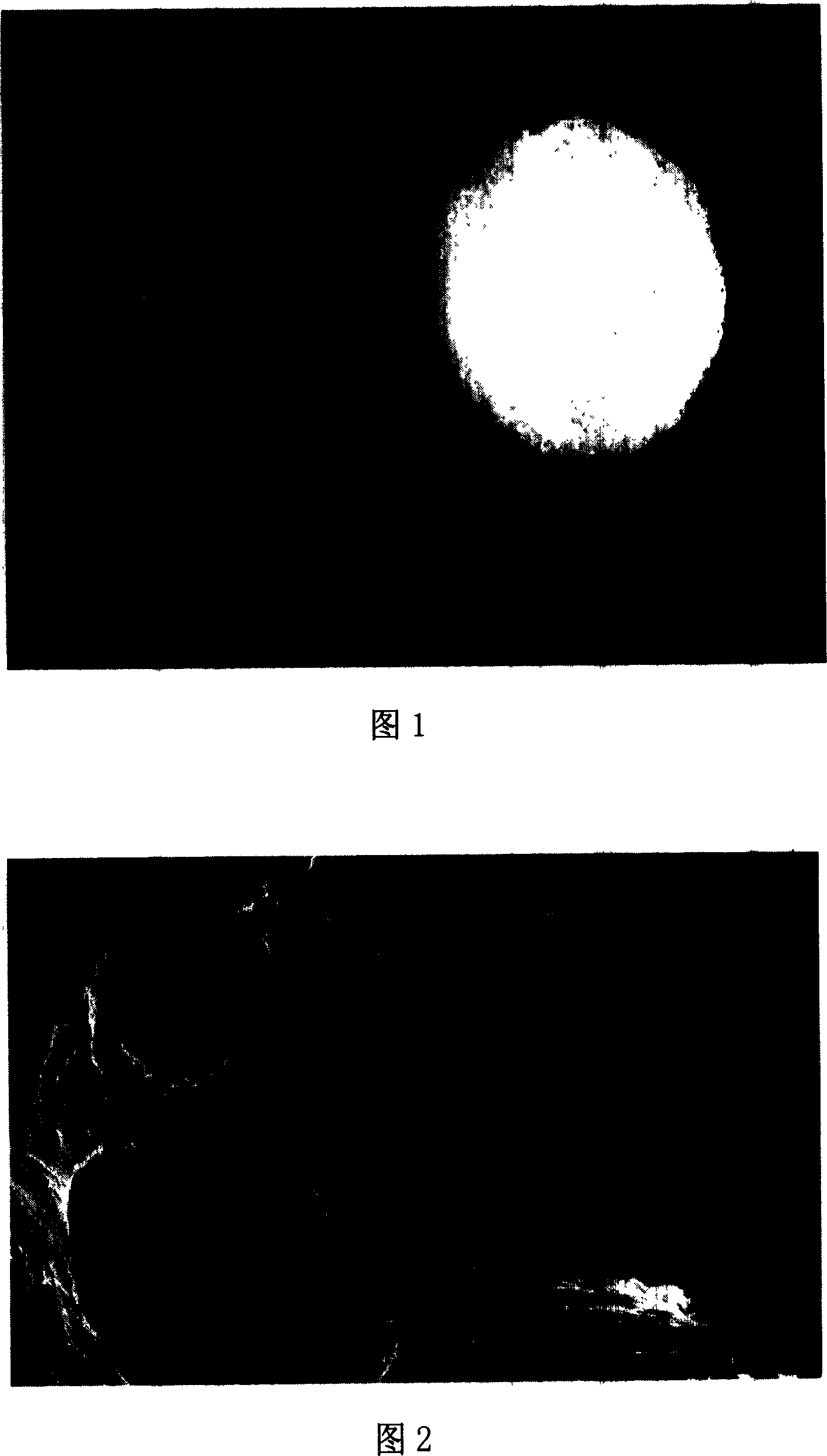

Image

Examples

Embodiment 1

[0020] Prepare a 10% polycaprolactone glacial acetic acid solution, take 30 g of the solution, add 0.75 g of chitosan powder, drop in 0.6 ml of water, and stir magnetically until a uniform solution is obtained. Then the solution was slowly poured into a 100ml beaker containing 30g of 40% NaOH solution under stirring, and left to stand for 24 hours to form. After molding, it was taken out and rinsed with distilled water for 10 times, soaked for 24 hours, and dried at 40° C. to obtain a polycaprolactone-chitosan porous scaffold material.

[0021] Prepare 50 ml of a 10% polyvinyl alcohol aqueous solution, add 5 g of nano-hydroxyapatite powder, and ultrasonically vibrate to prepare a hydroxyapatite / polyvinyl alcohol slurry.

[0022] Put the polycaprolactone-chitosan porous scaffold material into a centrifuge tube with a diameter of about 4 cm, and pour the hydroxyapatite / polyvinyl alcohol slurry. Centrifuge at 4000 rpm for 4 minutes, take it out and dry it in a 40°C constant-temp...

Embodiment 2

[0024] Prepare a polycaprolactone glacial acetic acid solution with a mass fraction of 5%, take 30 g of the solution, add 0.16 g of chitosan powder, drop in 0.15 ml of water, and stir magnetically until a uniform solution is obtained. Then the solution was slowly poured into a 100ml beaker containing 30g of 40% NaOH solution under stirring, and left to stand for 24 hours to form. After molding, it was taken out and rinsed with distilled water for 10 times, soaked for 24 hours, and dried at 40° C. to obtain a polycaprolactone-chitosan porous scaffold material.

[0025] Prepare 50 ml of 10% polyvinyl alcohol aqueous solution, add 2.5 g of nano-hydroxyapatite powder, and ultrasonically vibrate to prepare hydroxyapatite / polyvinyl alcohol slurry.

[0026] Put the polycaprolactone-chitosan porous scaffold material into a centrifuge tube with a diameter of about 4 cm, and pour the hydroxyapatite / polyvinyl alcohol slurry. Centrifuge at 10,000 rpm for 5 minutes, take it out and dry it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com