Multilayer optical device

A technology of optical components and lamination, applied in the direction of optical components, optics, coatings, etc., can solve problems such as difficult to manufacture optical components at low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

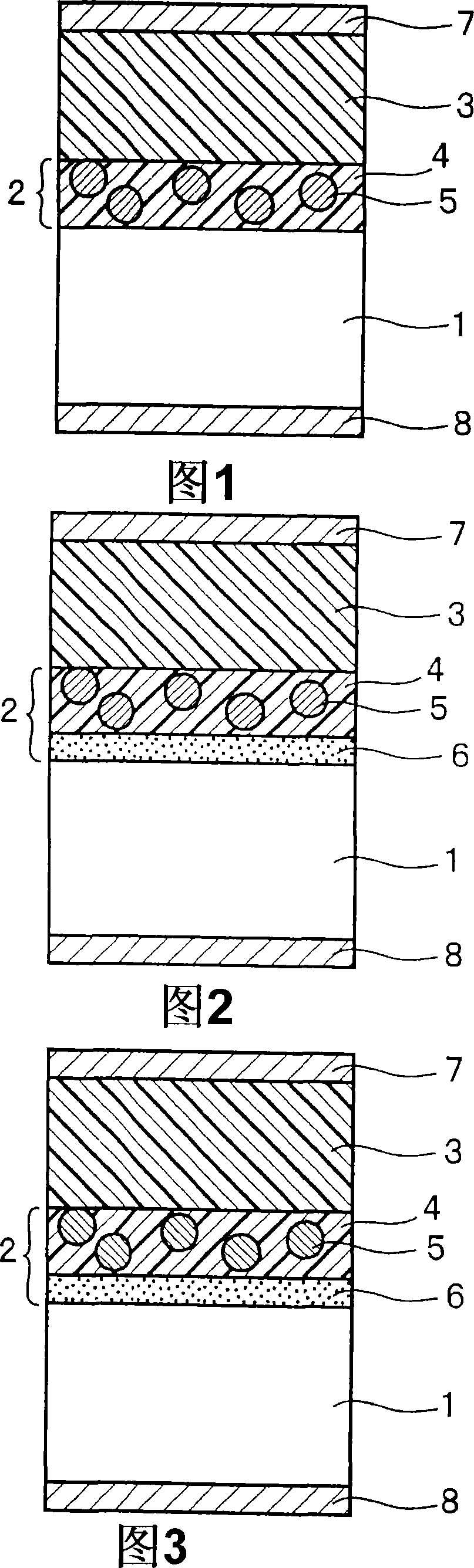

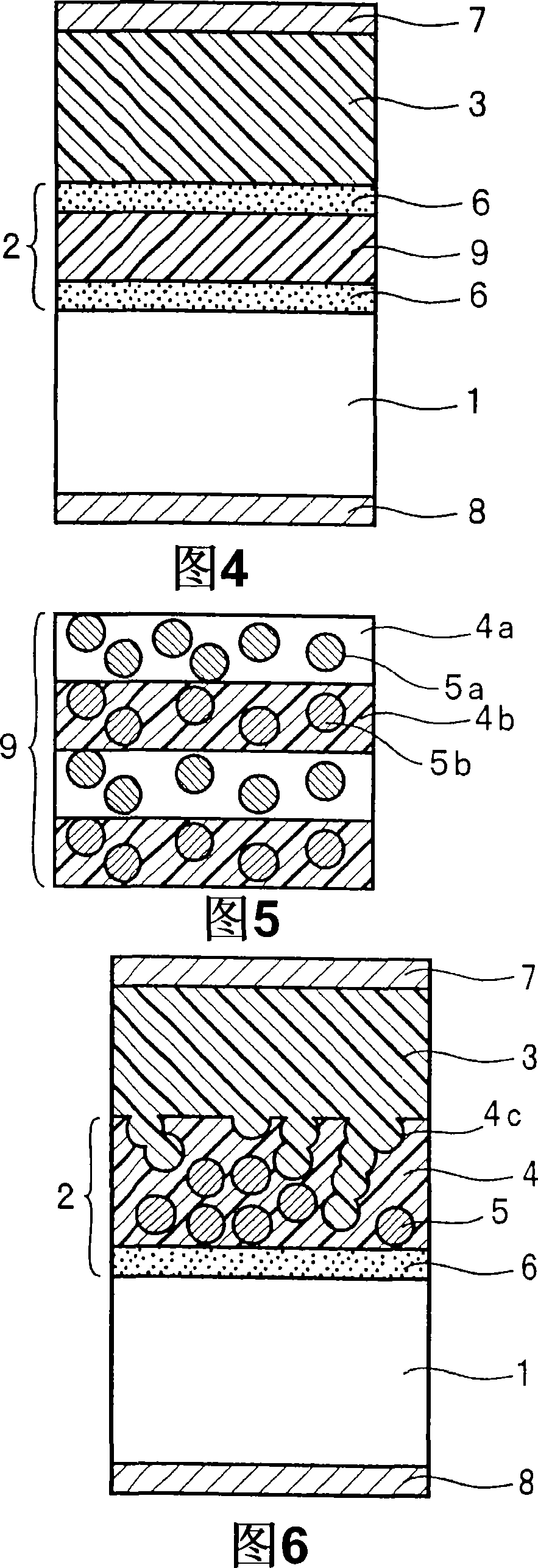

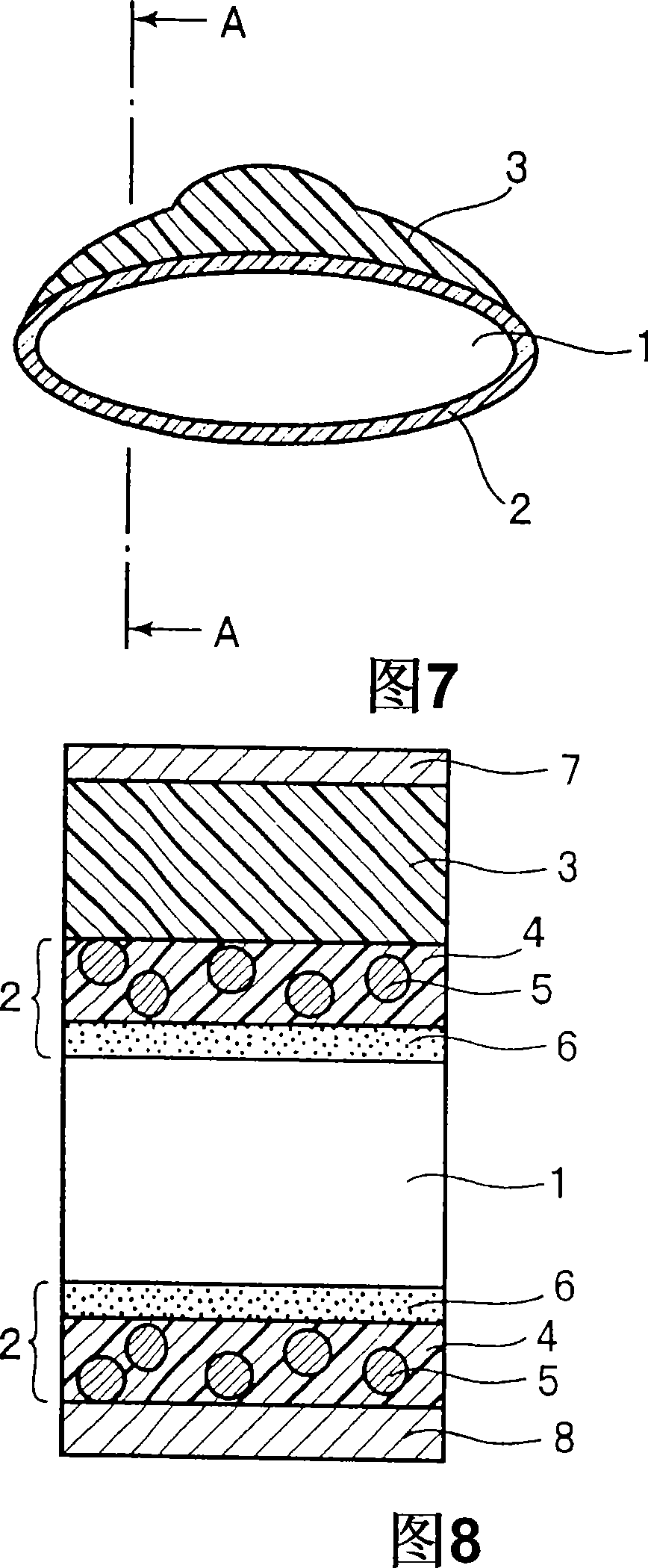

Embodiment 1

[0220]

[0221] A composite aspheric lens was manufactured by the manufacturing process shown in FIG. 11 .

[0222] As shown in FIG. 11( a ), a spherical lens made of glass is used as the optical base 1 , and after the intermediate layer 2 is formed on the optical base 1 , the solution 3 for forming an optical resin layer is dropped thereon. As the optical substrate 1, a high-refractive-index glass spherical lens (refractive index nD of glass = about 1.8) having a diameter of 5 mm and a maximum thickness of 1 mm was used. The intermediate layer 2 was formed by spin-coating a silicon oxide particle dispersion and heating at 100° C. for 1 hour.

[0223] As shown in FIG. 11( b ), the mold 10 made of nickel with an aspheric surface shape on the inner surface is pressed on the solution 3 for forming an optical resin layer, and then, as shown in FIG. 11( c ), irradiates The ultraviolet rays cure the optical resin layer forming solution 3 to form the optical resin layer 3 . Speci...

Embodiment 2

[0229] As shown in FIG. 2 , the intermediate layer 2 is formed by the coupling agent layer 6 provided on the optical substrate 1 and the matrix resin layer 4 in which the silicon oxide particles 5 are dispersed. In the same manner as in Example 1, a composite aspheric lens was produced.

[0230] The coupling agent layer 6 was formed by spin-coating the coupling agent solution 3 and heating at 140° C. for 1 hour. The thickness of the coupling agent layer 6 is 10 nm. The matrix resin layer 4 was formed in the same manner as in Example 1. Its maximum thickness is 200 nm.

[0231] Therefore, the thickness of the intermediate layer 2 in this embodiment is 210 nm.

Embodiment 3

[0233] In this embodiment, niobium oxide particles are used as the fine particles 5 . A composite aspherical lens was produced in the same manner as in Example 2 above except that the niobium oxide particle dispersion liquid was used for forming the matrix resin layer 4 to thereby use the niobium oxide particles as the microparticles 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com